The Releated Products of Automatic Stone Cutting Machine

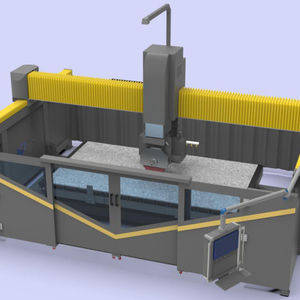

Automatic Stone Cutting Machine

Enhancing Efficiency with Automatic Stone Cutting Machines

In the dynamic landscape of construction and manufacturing, precision and efficiency are paramount. This is where automatic stone cutting machines come into play, revolutionizing how we process natural and engineered stones. These machines offer unparalleled accuracy, speed, and safety, making them indispensable in modern workshops.

Automatic Stone Cutting Machine: A Game-Changer in Precision

One of the most significant advantages of using an automatic stone cutting machine lies in its precision. With advanced technology such as computer numerical control (CNC), these machines can cut stones to exact specifications, ensuring minimal waste and maximum output quality. Whether it’s marble, granite, or quartz, the automatic stone cutting machine delivers flawless cuts every time, significantly reducing human error and increasing production efficiency.

Boosting Productivity Through Automation

Automation in stone cutting processes not only enhances precision but also boosts productivity levels. Traditional methods often require skilled labor and can be time-consuming. In contrast, an automatic stone cutting machine operates continuously without breaks, leading to a substantial increase in daily output. This makes it particularly beneficial for large-scale projects where deadlines are tight and quality must remain consistent.

Safety Features of Automatic Stone Cutting Machines

Safety is another critical aspect that sets automatic stone cutting machines apart from manual alternatives. Equipped with state-of-the-art safety features like emergency stop buttons, protective shields, and automated dust collection systems, these machines greatly reduce the risk of accidents in the workplace. Operators can focus on their tasks with peace of mind, knowing that stringent safety protocols are in place.

Maintenance Requirements for Automatic Stone Cutting Machines

To ensure optimal performance and longevity, regular maintenance of your automatic stone cutting machine is essential. Routine checks on key components such as blades, motors, and control systems help identify potential issues early on, preventing costly downtime. Manufacturers typically provide detailed guidelines on recommended maintenance schedules, which should be strictly followed to keep the machine running smoothly.

Environmental Benefits of Using Automatic Stone Cutting Machines

Beyond enhancing operational efficiency, automatic stone cutting machines contribute positively to environmental sustainability efforts. By optimizing material usage and reducing waste, they promote a more eco-friendly approach to stone processing. Additionally, advanced dust extraction technologies minimize airborne particulates, improving air quality both within the facility and surrounding areas.

Customization Options for Automatic Stone Cutting Machines

Recognizing the diverse needs of different industries, manufacturers now offer a wide range of customization options for automatic stone cutting machines. From compact models suitable for small workshops to heavy-duty industrial units, there’s a solution tailored to meet specific requirements. Customizable features such as blade size, cutting capacity, and automation level allow businesses to choose the configuration that best suits their operations.

By investing in an automatic stone cutting machine, companies can achieve higher standards of quality, productivity, and safety while contributing to sustainable practices. As technology continues to evolve, so too will the capabilities of these machines, promising even greater benefits for the future of stone processing.

Request for Quotation

报错: 未找到这个表单