The Releated Products of Best Diamond Wire Saw For Concrete

Best Diamond Wire Saw For Concrete

Table of Contents

Best Diamond Wire Saw For Concrete: Cutting Through Solid Structures with Precision

Diamond Wire Saws: The Ultimate Tool for Concrete Cutting

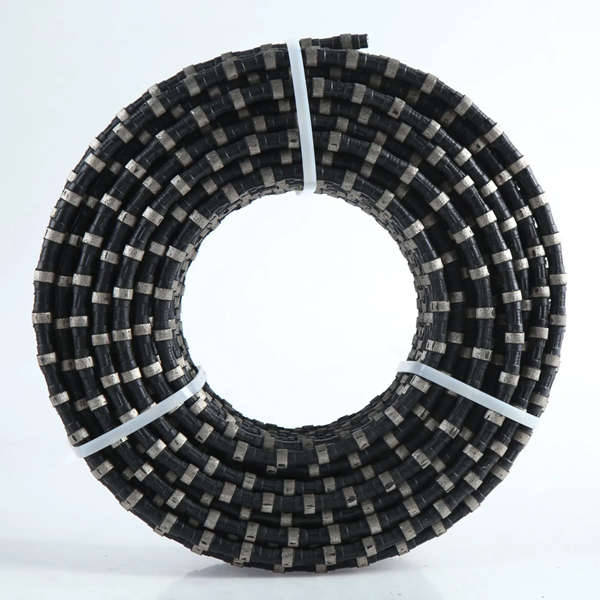

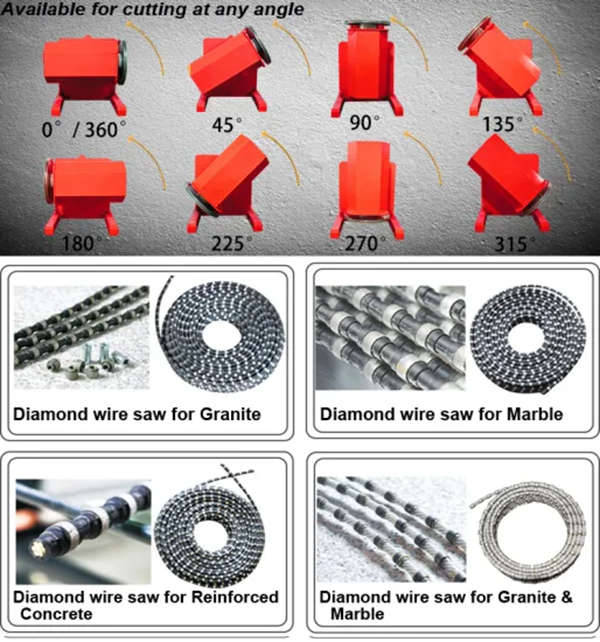

When it comes to cutting through dense materials like concrete, diamond wire saws stand out as one of the most effective tools available today. These saws utilize a thin, flexible wire embedded with diamond grains that rotate at high speeds to cut through even the toughest materials. A best diamond wire saw for concrete not only ensures precision but also increases efficiency on construction sites. Whether you’re working on demolition projects or making precise cuts in reinforced concrete, choosing the right diamond wire saw can make all the difference.

Choosing the Right Diamond Segments for Your Concrete Cutting Needs

The effectiveness of a diamond wire saw largely depends on the quality and type of diamond segments used. For concrete applications, selecting segments designed specifically for this material is crucial. Hardness, grain size, and concentration of diamonds within the segment all play a role in determining how well the saw will perform. A best diamond wire saw for concrete should feature robust segments capable of handling both fresh and hardened concrete, ensuring smooth operation and longevity.

Maintaining Optimal Performance: Tips for Using a Diamond Wire Saw on Concrete

To get the most out of your diamond wire saw when cutting concrete, proper usage and maintenance are key. Always ensure that the wire is properly tensioned before starting work. This prevents unnecessary wear and tear while maintaining cutting accuracy. Additionally, keeping the wire lubricated reduces friction and heat buildup, extending its life. Regular inspection of the wire and machine components helps identify potential issues early, ensuring uninterrupted performance during critical tasks.

Advantages of Using a High-Quality Diamond Wire Saw for Concrete Projects

Investing in a best diamond wire saw for concrete offers numerous benefits over traditional cutting methods. These include cleaner cuts with minimal material loss, reduced noise levels compared to other power tools, and the ability to cut intricate shapes and patterns with ease. Furthermore, because these saws produce less dust and debris, they contribute positively to workplace safety and environmental concerns. The versatility of diamond wire saws makes them indispensable in modern construction and demolition operations.

Factors to Consider When Selecting the Best Diamond Wire Saw for Concrete

Selecting the ideal diamond wire saw involves considering several factors tailored to your specific project requirements. Key considerations include the depth and thickness of the cut required, the hardness of the concrete, and whether the job involves wet or dry cutting conditions. It’s also important to evaluate the power source (electric vs. hydraulic), portability, and overall durability of the machine. Consulting with industry experts can provide valuable insights into choosing a best diamond wire saw for concrete that meets your unique needs.

Innovations in Diamond Wire Saw Technology for Enhanced Concrete Cutting

Recent advancements in diamond wire saw technology have significantly improved their performance in concrete cutting applications. Newer models often incorporate features such as advanced cooling systems, improved diamond segment designs, and more efficient motors. These innovations result in faster cutting speeds, increased precision, and longer operational lifespans. As manufacturers continue to refine these technologies, users can expect even better results from their diamond wire saws in the future.

By focusing on these aspects, professionals can confidently select and use a best diamond wire saw for concrete, enhancing productivity and achieving superior results in every project.

Request for Quotation

报错: 未找到这个表单