The Releated Products of Bridge Saw

Bridge Saw

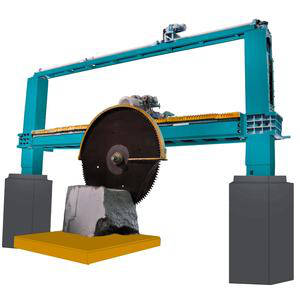

Understanding the Bridge Saw: A Precision Tool for Stone Fabrication

In the world of stone fabrication, precision and efficiency are paramount. This is where the bridge saw shines, offering unparalleled accuracy and speed in cutting hard materials like granite, marble, and quartz. Whether you’re a seasoned professional or just starting out in the industry, understanding the intricacies of a bridge saw can significantly enhance your workflow and final product quality.

Bridge Saw Basics: How It Works

A bridge saw consists of a large frame that supports a bridge-like structure. This structure houses the cutting head, which moves along rails on the bridge, allowing for precise linear cuts. The cutting head typically includes a water-cooled diamond blade, essential for slicing through dense stone materials. Water not only cools the blade but also helps in dust suppression, ensuring a safer work environment.

Key Components of a Bridge Saw

Several key components contribute to the functionality and durability of a bridge saw:

– Bridge Frame: This robust structure provides stability during operation.

– Cutting Head: Equipped with a powerful motor and diamond blade, it’s responsible for making clean, accurate cuts.

– Rails and Linear Guides: These ensure smooth movement of the cutting head across the material.

– Control Panel: Modern bridge saws feature advanced control systems for setting cut parameters and controlling machine functions.

Benefits of Using a Bridge Saw

The advantages of using a bridge saw over traditional hand-held tools or other cutting methods are numerous:

– Increased Productivity: With its ability to make quick, straight cuts, a bridge saw can process more material in less time.

– Enhanced Accuracy: Digital controls and laser guides improve cut precision, reducing waste and improving overall quality.

– Safety Improvements: Automated processes reduce operator exposure to dust and sharp edges, contributing to a safer workplace.

Applications of Bridge Saws in Industry

Bridge saws find extensive use across various industries dealing with stone and similar materials:

– Countertop Fabrication: Ideal for creating custom countertops from slabs of granite or marble.

– Tile Cutting: Perfect for producing tiles of specific dimensions from larger sheets of stone.

– Memorial Stones and Sculptures: Used by artisans to carve intricate designs and shapes into solid blocks of stone.

Maintenance Tips for Your Bridge Saw

To keep your bridge saw running smoothly and extend its lifespan, regular maintenance is crucial:

– Blade Care: Regularly inspect and replace worn blades to maintain cutting efficiency.

– Lubrication: Apply lubricants to moving parts as recommended by the manufacturer.

– Cleaning: Remove debris and dust regularly, especially from the rail system, to prevent wear and tear.

Choosing the Right Bridge Saw for Your Needs

Selecting the appropriate bridge saw depends on several factors, including the scale of your operations, types of materials you work with, and budget constraints. Consider consulting with industry experts or equipment suppliers to determine the best fit for your business. By investing in a high-quality bridge saw tailored to your specific requirements, you can achieve superior results while maximizing productivity and cost-effectiveness.

Bridge saws represent a significant investment for any workshop or fabrication facility. However, their ability to deliver consistent, high-quality cuts makes them indispensable tools in the modern stonework industry. Proper selection, usage, and maintenance will ensure that your bridge saw continues to be a valuable asset for years to come.

Request for Quotation

报错: 未找到这个表单