The Releated Products of Buy Diamond Wire Saw

Buy Diamond Wire Saw

Table of Contents

Buying Diamond Wire Saws: A Comprehensive Guide

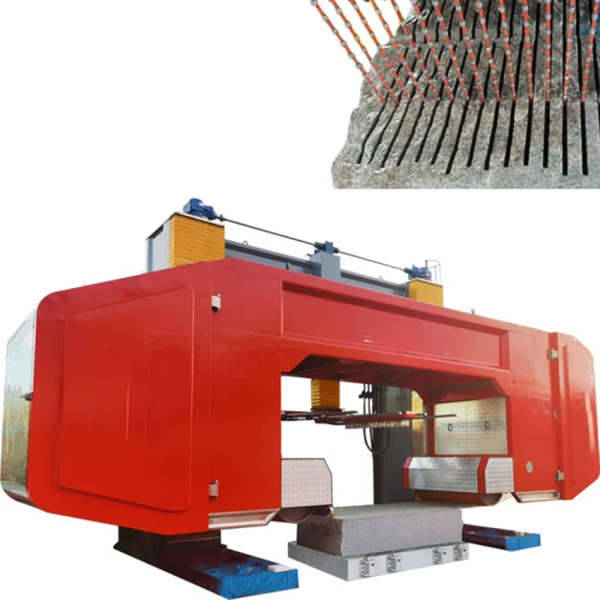

When it comes to precision cutting in hard materials such as stone, concrete, or reinforced concrete, diamond wire saws stand out as one of the most effective tools available today. Their ability to cut through tough materials with minimal vibration and maximum accuracy makes them indispensable in various industries. If you’re considering buying diamond wire saws, this guide will walk you through the essential factors to consider, helping you make an informed decision.

Why Buy Diamond Wire Saws?

Before diving into the specifics, it’s important to understand why these tools are so highly regarded. Diamond wire saws offer several advantages over traditional cutting methods. They can cut in any direction, making them versatile for complex projects. Additionally, they produce minimal noise and dust, improving working conditions and reducing environmental impact. The wire’s thin profile also means less material waste, which can be a significant cost-saving factor in large-scale operations.

Factors to Consider When Buying Diamond Wire Saws

Blade Quality Determines Performance

One of the primary considerations when buying diamond wire saws is the quality of the blade. The blade’s durability and efficiency depend largely on the grade and concentration of diamonds embedded in the wire. Higher quality diamonds will ensure a longer-lasting tool capable of handling more demanding tasks without frequent replacement. It’s also crucial to match the blade type to the specific material being cut for optimal performance.

Machine Compatibility and Configuration

When buying diamond wire saws, compatibility with your existing machinery is another critical aspect. Not all saws fit every machine, so ensuring that the saw you purchase works seamlessly with your setup can save you from potential headaches later. Additionally, consider the configuration of the saw—whether it’s suitable for indoor or outdoor use, wet or dry cutting, and whether it meets the specific requirements of your project.

Cost vs. Benefits Analysis

Investing in diamond wire saws involves weighing the initial cost against the long-term benefits. While these tools might come with a higher price tag compared to some alternatives, their longevity and efficiency often justify the expense. By reducing downtime and increasing productivity, they can quickly pay for themselves. Always look for models that offer the best value for money based on your operational needs and budget constraints.

Maintenance and Support Services

The longevity and reliability of diamond wire saws are significantly influenced by how well they are maintained. Before making a purchase, inquire about the manufacturer’s maintenance recommendations and the availability of support services. Regular servicing and access to spare parts can extend the life of your saw, ensuring continuous operation and minimizing costly downtimes.

Conclusion

Buying diamond wire saws is a decision that should not be taken lightly. With the right considerations in mind, you can choose a tool that enhances your capabilities, improves efficiency, and stands up to the demands of your projects. Whether you’re tackling small-scale jobs or large industrial applications, investing in high-quality diamond wire saws will undoubtedly elevate your work processes. Remember, the key lies in understanding your specific needs and selecting a product that aligns with those requirements.

Request for Quotation

报错: 未找到这个表单