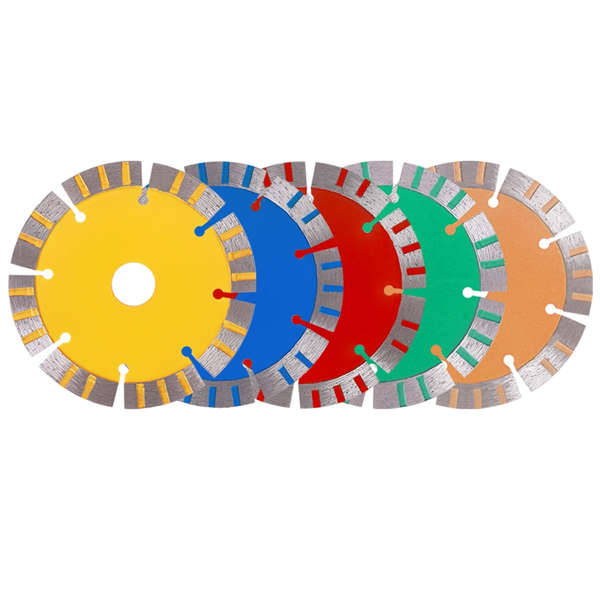

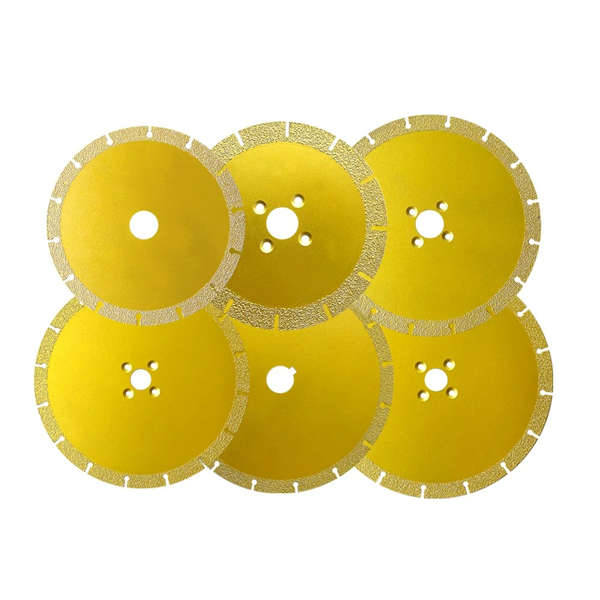

The Releated Products of Carbide-grit Ceramic-tile Hole Saw

Carbide-grit Ceramic-tile Hole Saw

Carbide-grit Ceramic-tile Hole Saw: Precision Cutting for Tough Materials

When it comes to drilling through ceramic tiles, finding the right tool can make all the difference. A carbide-grit ceramic-tile hole saw is specifically designed to handle these demanding tasks with ease and precision. This article will explore the features, benefits, and proper usage of carbide-grit ceramic-tile hole saws, ensuring your next project goes smoothly.

Understanding the Composition of Carbide-grit Ceramic-tile Hole Saws

The key to the effectiveness of a carbide-grit ceramic-tile hole saw lies in its construction. These tools feature a steel body coated with industrial-grade carbide grit. The carbide coating provides superior abrasion resistance and durability compared to standard hole saws. This composition allows the saw to cut through hard materials like ceramic tiles without chipping or breaking the surface, resulting in clean, precise holes.

Benefits of Using Carbide-grit Ceramic-tile Hole Saws

Using a carbide-grit ceramic-tile hole saw offers several advantages over traditional cutting methods. Firstly, they provide increased efficiency and speed when cutting through ceramics. Secondly, the reduced wear and tear on the tool mean you’ll need to replace them less frequently, saving money in the long run. Lastly, because of their specialized design, these hole saws produce minimal dust and debris, making cleanup easier and safer.

Proper Technique for Using Carbide-grit Ceramic-tile Hole Saws

To get the best results from your carbide-grit ceramic-tile hole saw, it’s important to use it correctly. Start by marking the center point of where you want to drill on the tile. Apply light pressure as you begin drilling, allowing the saw to do most of the work. Maintain steady pressure and avoid forcing the tool, which could lead to overheating or damage to the tile. For larger holes, periodically withdraw the saw to clear debris and allow it to cool.

Maintenance and Care of Carbide-grit Ceramic-tile Hole Saws

Like any tool, proper maintenance is crucial for extending the life of your carbide-grit ceramic-tile hole saw. After each use, clean the saw thoroughly to remove any residue or debris. Store it in a dry place to prevent rusting. Periodically inspect the carbide grit coating for signs of wear or damage; if significant wear is observed, consider replacing the saw to maintain optimal performance.

Applications of Carbide-grit Ceramic-tile Hole Saws

Carbide-grit ceramic-tile hole saws are versatile tools that find applications in various industries. They are particularly useful in home renovation projects where installing fixtures or electrical outlets requires drilling through ceramic tiles. In commercial settings, such as restaurants or hotels, these hole saws are indispensable for maintaining and upgrading facilities without causing unnecessary damage to existing structures.

Choosing the Right Size of Carbide-grit Ceramic-tile Hole Saw

Selecting the correct size of carbide-grit ceramic-tile hole saw depends on the specific requirements of your project. Common sizes range from 1/2 inch to 6 inches in diameter. Always measure the space where the hole needs to be made and choose a saw that matches or slightly exceeds this measurement. Larger holes may require special techniques or multiple passes to achieve the desired result.

By understanding the features, benefits, and proper usage of carbide-grit ceramic-tile hole saws, you can tackle even the toughest cutting jobs with confidence. Whether you’re a professional contractor or a DIY enthusiast, investing in quality tools like these will undoubtedly improve your workmanship and efficiency.

Request for Quotation

报错: 未找到这个表单