The Releated Products of Ceramic Hack Saw

Ceramic Hack Saw

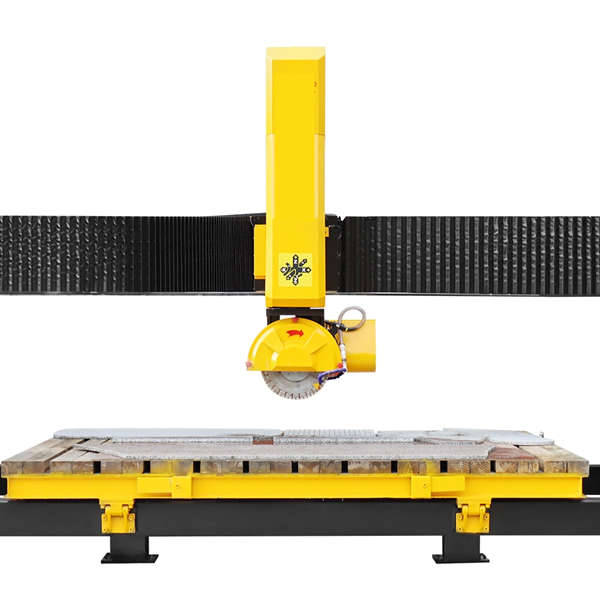

Ceramic Hack Saw: Precision Cutting for Advanced Materials

Ceramic hack saws have become indispensable tools in industries requiring precise and efficient cutting of hard materials such as ceramics, certain types of metals, and composite materials. These specialized saws offer a level of precision and durability that traditional metal-bladed saws cannot match when it comes to working with non-ferrous materials. In this article, we explore the benefits, applications, and maintenance of ceramic hack saws, highlighting their role in modern manufacturing processes.

Ceramic Hack Saw Blades: A Closer Look

The key component of any ceramic hack saw is its blade. Unlike conventional steel blades, ceramic blades are made from highly durable materials like tungsten carbide or silicon carbide. These materials are chosen for their exceptional hardness and resistance to wear, making them ideal for cutting through tough materials without significant degradation. The result is a tool capable of maintaining sharpness over prolonged periods, reducing downtime associated with frequent blade changes.

Applications of Ceramic Hack Saws

From aerospace engineering to microelectronics, the application of ceramic hack saws spans across various sectors where precision and accuracy are paramount. In the production of semiconductor wafers, for instance, these saws enable clean, accurate cuts that preserve the integrity of delicate materials. Similarly, in the fabrication of ceramic components used in high-temperature environments (e.g., jet engines), ceramic hack saws provide the necessary precision to ensure parts meet stringent specifications.

Benefits of Using Ceramic Hack Saws

One major benefit of using ceramic hack saws lies in their ability to achieve cleaner cuts compared to traditional alternatives. This is particularly important when working with materials that are prone to chipping or cracking under stress. Additionally, because ceramic blades retain their edge longer, they contribute to increased productivity by minimizing the frequency of blade replacements. This translates into cost savings over time, as well as improved efficiency on the shop floor.

Maintenance and Care of Ceramic Hack Saws

To ensure optimal performance and longevity, proper maintenance of ceramic hack saws is essential. Regular cleaning of the blade to remove debris and residue is crucial. Special care must be taken during storage to prevent accidental damage to the blade’s edge. It’s also advisable to periodically inspect the blade for signs of wear or damage, replacing it as needed to maintain cutting quality and safety standards.

Advancements in Ceramic Hack Saw Technology

Innovation continues to drive improvements in ceramic hack saw technology, pushing the boundaries of what these tools can achieve. Recent developments focus on enhancing blade composition to further improve durability and cutting efficiency. Some manufacturers are experimenting with new coatings designed to reduce friction and heat generation during operation, which could lead to even cleaner cuts and extended blade life. As research progresses, we can expect ceramic hack saws to play an increasingly important role in advanced manufacturing techniques.

Choosing the Right Ceramic Hack Saw

Selecting the appropriate ceramic hack saw for your specific needs involves considering several factors, including the type of material being cut, the required precision level, and the frequency of use. For occasional cutting tasks, a basic model might suffice. However, for regular industrial applications, investing in a higher-end saw with features like variable speed control and adjustable guides can significantly enhance both comfort and productivity. Consulting with experts or experienced users within your industry can provide valuable insights when making this decision.

Ceramic hack saws represent a significant advancement in cutting technology, offering unparalleled precision and durability for demanding applications. By understanding their capabilities and limitations, manufacturers can leverage these tools to improve efficiency, quality, and ultimately, their competitive edge in today’s global marketplace.

Request for Quotation

报错: 未找到这个表单