The Releated Products of Ceramic Saw

Ceramic Saw

Understanding Ceramic Saws: Precision Cutting for Advanced Materials

In the realm of advanced cutting technologies, ceramic saws have emerged as indispensable tools for precision work. Whether you’re dealing with ceramics, glass, or other brittle materials, these specialized machines offer unparalleled accuracy and efficiency. This article delves into the world of ceramic saws, exploring their applications, benefits, and how they operate.

Ceramic Saws: A Brief Overview

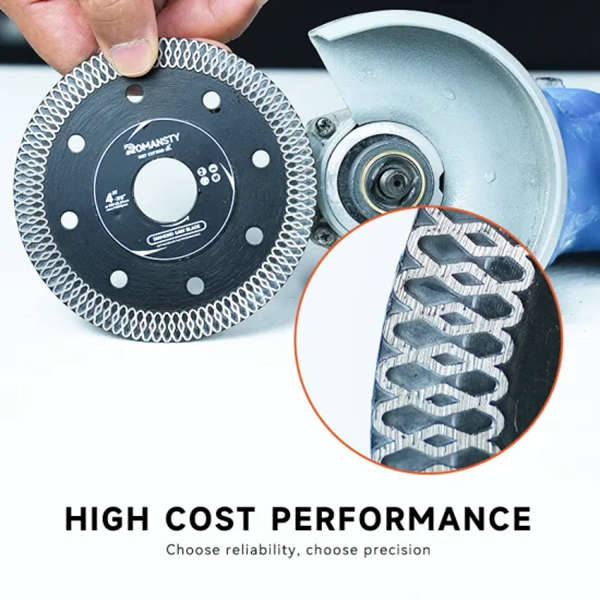

Ceramic saws are designed specifically to cut through hard, brittle materials like ceramics, porcelain, and certain types of glass. These saws use diamond blades, which are incredibly durable and can maintain sharpness even when slicing through some of the toughest materials. The key to their effectiveness lies in the blade’s composition and the machine’s ability to control the cutting process with high precision.

Applications of Ceramic Saws in Industry

The versatility of ceramic saws makes them essential across various industries. In electronics manufacturing, they are used to cut silicon wafers with incredible accuracy. Similarly, in construction and architecture, ceramic saws enable precise cuts on tiles and other decorative materials, ensuring a seamless finish. Moreover, their use extends to the aerospace sector where precision is paramount in material processing.

How Ceramic Saws Work

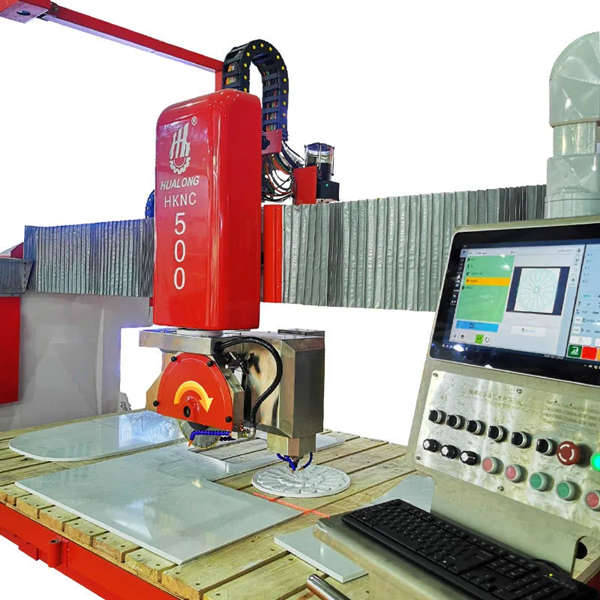

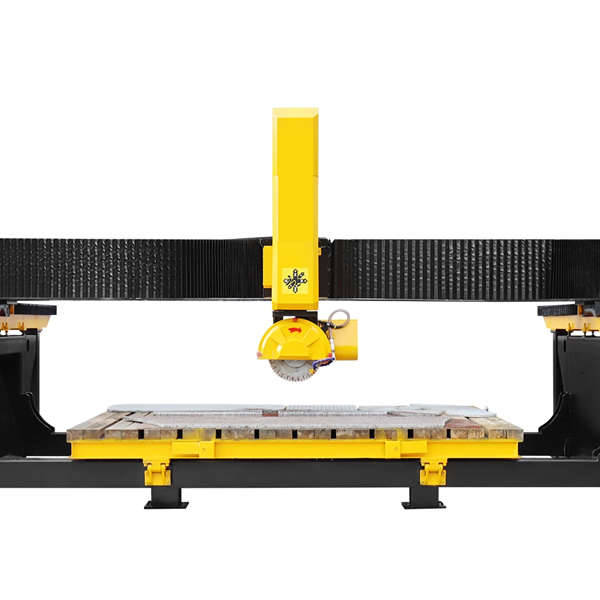

Understanding how ceramic saws function provides insight into why they are so effective. These machines typically consist of a motor-driven diamond blade, a water cooling system to prevent overheating, and a sturdy frame to hold everything together. The operator controls the speed and depth of the cut, allowing for adjustments based on the material being cut and the desired outcome.

Benefits of Using Ceramic Saws

The primary benefit of using ceramic saws is their ability to achieve clean, straight cuts without chipping or cracking the material. This is particularly important when working with expensive or delicate items. Additionally, these saws are relatively easy to operate once you understand the basics, making them accessible to both professionals and hobbyists alike.

Maintenance and Care for Ceramic Saws

Like any piece of machinery, ceramic saws require regular maintenance to ensure optimal performance and longevity. Keeping the diamond blade clean and free from debris is crucial. It’s also important to check the water supply system regularly to avoid issues related to overheating. Proper storage and occasional servicing by a professional technician will help keep your ceramic saw running smoothly.

Choosing the Right Ceramic Saw

When selecting a ceramic saw, consider factors such as the size of the blade, the power of the motor, and additional features like adjustable cutting angles. For most DIY projects, a smaller, more portable model might suffice. However, industrial applications often demand larger, more robust machines capable of handling continuous heavy-duty use.

By understanding the capabilities and proper usage of ceramic saws, users can maximize their potential and achieve outstanding results in their respective fields. Whether you’re a professional looking to upgrade your workshop equipment or a hobbyist seeking new tools, investing in a quality ceramic saw is a step towards achieving precision and excellence in your work.

Request for Quotation

报错: 未找到这个表单