The Releated Products of Ceramic Tile Chipping Wet Saw

Ceramic Tile Chipping Wet Saw

The Precision and Power of Ceramic Tile Chipping Wet Saws

Understanding Ceramic Tile Chipping Wet Saws

Ceramic tile chipping wet saws are indispensable tools for professionals and DIY enthusiasts alike who require precise cuts without damaging the delicate edges of ceramic tiles. These specialized saws not only ensure clean, straight cuts but also minimize chipping, a common issue when working with hard, brittle materials like ceramics.

When choosing a ceramic tile chipping wet saw, it’s essential to consider several factors such as blade size, water flow rate, and adjustability. A good wet saw will have a powerful motor capable of handling various tile thicknesses while maintaining steady, controlled cutting speeds. Additionally, the inclusion of a water pump system helps keep the blade cool and reduces dust, making the workspace safer and cleaner.

Benefits of Using a Ceramic Tile Chipping Wet Saw

One of the primary benefits of using a ceramic tile chipping wet saw is its ability to reduce material waste. By minimizing chipping and breakage during the cutting process, these saws help save on both time and resources. Another advantage is the precision they offer. With adjustable guides and fences, users can achieve accurate cuts repeatedly, which is crucial for creating complex patterns or fitting tiles into tight spaces.

Moreover, wet saws designed specifically for ceramic tiles often come equipped with features that enhance user comfort and safety. Ergonomic handles, anti-vibration technology, and splash guards are just some of the elements that make working with these tools more pleasant and secure. Lastly, the continuous water supply ensures that the blade remains free from overheating, extending its lifespan significantly.

How to Choose the Right Ceramic Tile Chipping Wet Saw

Selecting the right ceramic tile chipping wet saw depends largely on your specific needs and the scale of your projects. For instance, if you’re frequently working with large-format tiles or undertaking commercial installations, investing in a model with a larger cutting capacity would be beneficial. On the other hand, those engaged in smaller, more intricate jobs might prefer a compact unit with finer control over cut angles and depths.

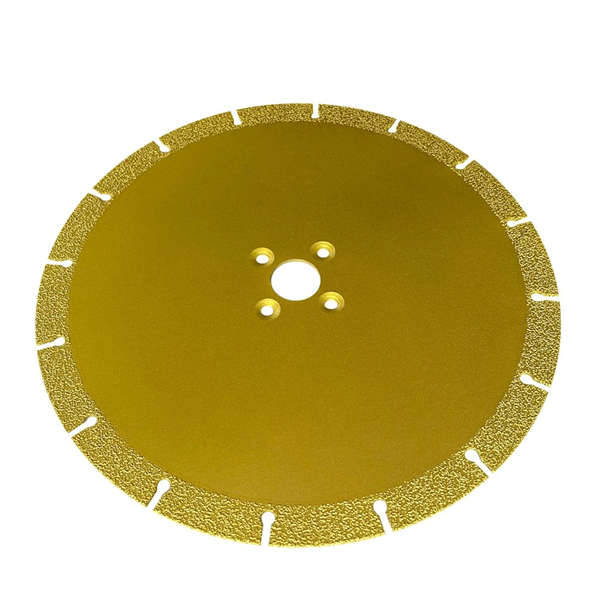

Consider also the power output of the saw. Higher wattage motors provide more torque, allowing for faster cutting through denser materials. Blade quality is equally important; diamond blades, for example, are ideal for cutting ceramics due to their durability and sharpness. Finally, look for a wet saw with easy-to-use adjustments and a robust construction that can withstand regular use.

Maintaining Your Ceramic Tile Chipping Wet Saw

Proper maintenance is key to ensuring your ceramic tile chipping wet saw performs optimally throughout its service life. Regular cleaning of the saw’s components, particularly the water pump and filtration system, prevents clogging and ensures efficient operation. It’s also advisable to inspect the blade periodically for signs of wear or damage and replace it when necessary to maintain cutting accuracy.

Lubricating moving parts like pivot points and guide rods can help reduce friction and extend the saw’s longevity. Storing the tool in a dry place when not in use protects against rust formation, especially on metal parts. Lastly, always refer to the manufacturer’s guidelines for any specific care instructions or recommended maintenance schedules.

Tips for Safe Operation of Ceramic Tile Chipping Wet Saws

Safety should always come first when operating any power tool, including ceramic tile chipping wet saws. Always wear appropriate personal protective equipment (PPE), such as safety glasses, gloves, and ear protection, to shield yourself from flying debris and noise. Ensure that the work area is well-lit and free from clutter to avoid accidents.

Before starting the saw, double-check that all guards are in place and functioning correctly. Never force the blade through the material; allow the saw to do the work at its own pace to prevent kickback or loss of control. If possible, clamp down the tile being cut to keep it stable and reduce the risk of slipping.

By following these guidelines and investing in a high-quality ceramic tile chipping wet saw, you’ll be well-equipped to tackle even the most challenging tiling projects with confidence and precision.

Request for Quotation

报错: 未找到这个表单