The Releated Products of Ceramic Tile Hole Saw Manufacturer

Ceramic Tile Hole Saw Manufacturer

Understanding Ceramic Tile Hole Saw Manufacturers

Ceramic tile hole saws are essential tools for professionals and DIY enthusiasts working with ceramics, porcelain, and other hard surfaces. These specialized cutting tools allow for precise and clean cuts, making them indispensable in various applications such as plumbing, electrical work, and decorative installations. As the demand for high-quality ceramic tile hole saws increases, so does the importance of choosing the right manufacturer.

Selecting the Right Ceramic Tile Hole Saw Manufacturer

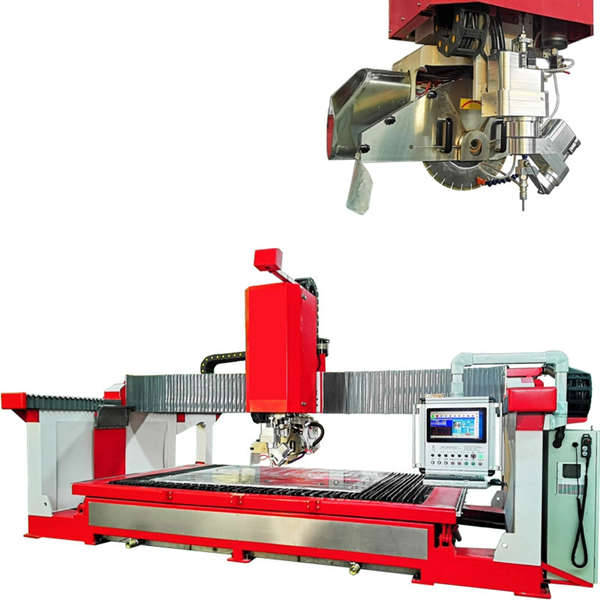

When selecting a ceramic tile hole saw manufacturer, consider factors like reputation, product quality, and customer service. A reputable manufacturer will have a track record of producing durable, efficient hole saws that meet industry standards. They should also offer a wide range of sizes to accommodate different project needs, from small-diameter holes for faucets to larger ones for electrical fixtures.

Benefits of Working with a Ceramic Tile Hole Saw Manufacturer

Partnering with a reliable ceramic tile hole saw manufacturer can significantly enhance your project outcomes. High-quality hole saws reduce the risk of chipping or cracking tiles during the drilling process, ensuring a professional finish. Moreover, manufacturers often provide technical support and advice on best practices, helping users achieve optimal results.

The Role of Technology in Ceramic Tile Hole Saw Manufacturing

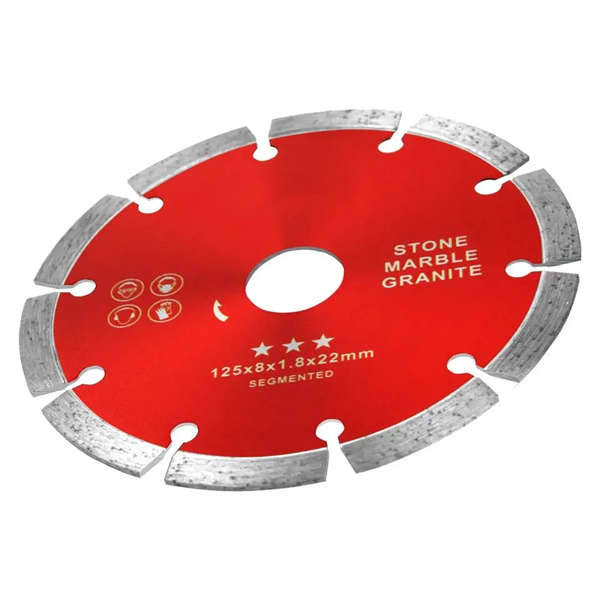

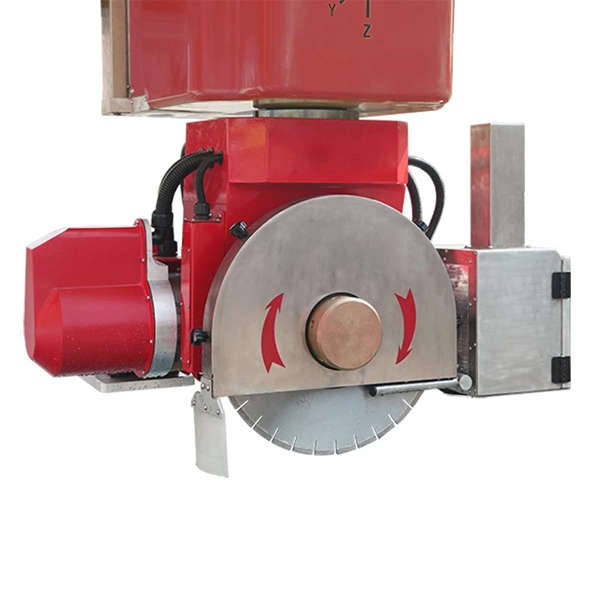

Advancements in manufacturing technology have led to the development of more efficient and effective ceramic tile hole saws. Techniques such as laser welding and diamond coating improve the durability and performance of these tools. Laser welding ensures that the cutting segment remains securely attached to the steel body, even under heavy use. Diamond coating provides enhanced abrasion resistance, allowing the hole saw to cut through dense materials with ease.

Custom Solutions from Ceramic Tile Hole Saw Manufacturers

Many ceramic tile hole saw manufacturers offer custom solutions tailored to specific project requirements. This could include special sizes, coatings, or design modifications that better suit unique applications. Customization ensures that you have the right tool for every job, improving efficiency and reducing waste.

Ensuring Quality in Ceramic Tile Hole Saw Production

Quality control is crucial in the production of ceramic tile hole saws. Leading manufacturers implement rigorous testing procedures throughout the manufacturing process to ensure that each product meets stringent standards. This includes checking for consistency in the diamond grit distribution, verifying the strength of welds, and assessing overall durability.

Sustainability Initiatives by Ceramic Tile Hole Saw Manufacturers

Increasingly, ceramic tile hole saw manufacturers are adopting sustainable practices in their operations. This might involve using recycled materials in packaging, optimizing production processes to reduce energy consumption, or investing in renewable energy sources. Such initiatives not only benefit the environment but also contribute to a positive brand image and customer loyalty.

By focusing on these aspects, manufacturers can continue to innovate and deliver top-tier ceramic tile hole saws that meet the evolving needs of their customers. Whether you’re a seasoned professional or a DIY enthusiast, partnering with a dedicated ceramic tile hole saw manufacturer will undoubtedly elevate your projects and ensure lasting results.

Request for Quotation

报错: 未找到这个表单