The Releated Products of Circular Saw Blade For Cutting Granite

Circular Saw Blade For Cutting Granite

Table of Contents

Circular Saw Blade for Cutting Granite: Precision and Durability

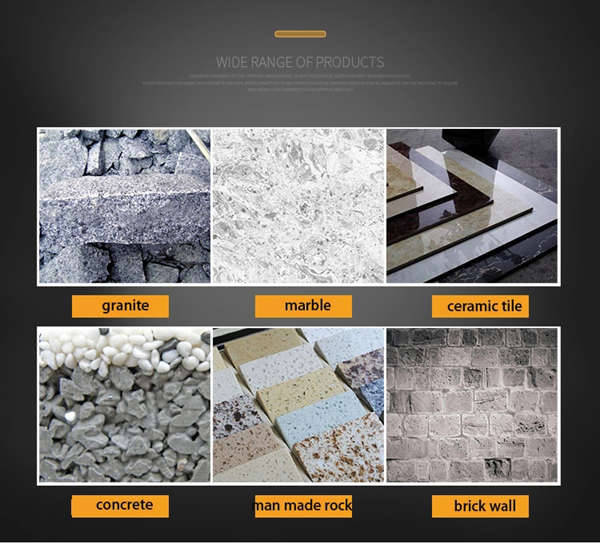

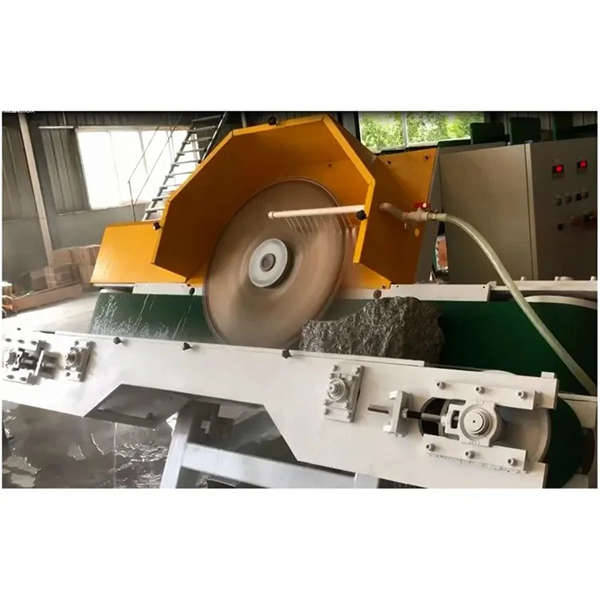

When it comes to cutting granite, a material known for its hardness and durability, choosing the right tool is crucial. A circular saw blade for cutting granite must be designed specifically to handle this demanding task. Not all blades are created equal, and using the wrong one can lead to poor cuts, decreased blade life, and even dangerous kickbacks. This article will guide you through the key considerations when selecting a circular saw blade for cutting granite, ensuring that your projects are completed with precision and safety.

Choosing the Right Diameter for Your Circular Saw Blade for Cutting Granite

The diameter of your circular saw blade for cutting granite plays a significant role in how effectively it performs. Larger diameters allow for deeper cuts, which is essential when working on thick slabs of granite. However, larger blades also require more power from the saw, so ensure that your saw has enough horsepower to handle the load. Smaller blades are more suitable for thinner materials or when maneuverability is a priority. When selecting the diameter, consider the thickness of the granite and the type of cuts required.

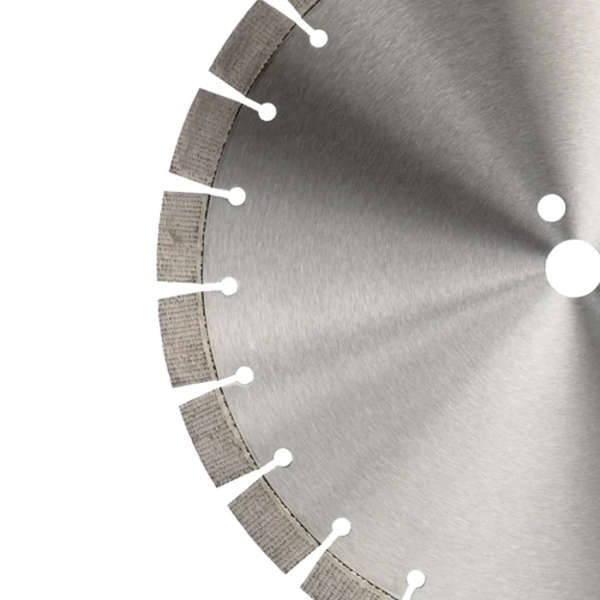

Understanding the Importance of Tooth Configuration on Your Circular Saw Blade for Cutting Granite

Tooth configuration is another critical factor to consider when choosing a circular saw blade for cutting granite. The number and type of teeth on the blade determine its cutting speed and quality. For granite, a high tooth count is typically preferred as it provides a smoother cut. Additionally, the type of tooth (such as carbide-tipped) is important because it directly affects the blade’s ability to withstand the abrasive nature of granite. Carbide-tipped teeth are ideal due to their exceptional hardness and durability, making them perfect for cutting through dense materials like granite.

Tips for Maintaining Your Circular Saw Blade for Cutting Granite

Maintaining your circular saw blade for cutting granite properly can extend its lifespan and ensure optimal performance. After each use, clean the blade thoroughly to remove any debris or dust that could affect its cutting efficiency. Regularly inspect the blade for signs of wear or damage, such as chipped teeth or cracks. Prompt replacement of worn blades not only improves cutting results but also enhances safety during operation. Following the manufacturer’s guidelines for maintenance and storage is crucial for keeping your blade in top condition.

Safety Precautions When Using a Circular Saw Blade for Cutting Granite

Safety should always be a top priority when operating any power tool, especially when working with a circular saw blade for cutting granite. Always wear appropriate personal protective equipment (PPE), including safety glasses, ear protection, and a dust mask. Ensure that the work area is well-lit and free of clutter to avoid accidents. Keep the blade guard in place and use a push stick or other holding devices to maintain control over the material being cut. Never force the blade; let the saw do the work to prevent kickbacks and other hazards.

Selecting the Correct Arbor Size for Your Circular Saw Blade for Cutting Granite

The arbor is the shaft that holds the circular saw blade for cutting granite in place. It’s essential to choose a blade with the correct arbor size to fit your specific saw model. An ill-fitting arbor can cause the blade to wobble, leading to uneven cuts and potential safety issues. Most saws have a standard arbor size, but double-check your model’s specifications before purchasing a new blade. Adapters are available if you need to use a blade with a different arbor size, but using the correct fit is always preferable.

Conclusion: Making Informed Choices About Your Circular Saw Blade for Cutting Granite

By considering factors such as blade diameter, tooth configuration, maintenance needs, safety precautions, and arbor size, you can make informed decisions about the best circular saw blade for cutting granite. These choices will not only improve your project outcomes but also enhance your overall experience and safety when working with this challenging material. Remember, investing in a high-quality blade is just as important as having the right technique and mindset. With the right tools and knowledge, cutting granite can be both efficient and enjoyable.

Request for Quotation

报错: 未找到这个表单