The Releated Products of Cnc Diamond Wire Saw Machine Factory

Cnc Diamond Wire Saw Machine Factory

Table of Contents

CNC Diamond Wire Saw Machine Factory: Precision Engineering for Modern Manufacturing

In the dynamic landscape of modern manufacturing, precision and efficiency are paramount. The CNC Diamond Wire Saw Machine Factory stands as a beacon of innovation, offering unparalleled accuracy and speed in material cutting processes. This article delves into the intricacies of these factories, exploring their capabilities, applications, and the technological advancements driving their evolution.

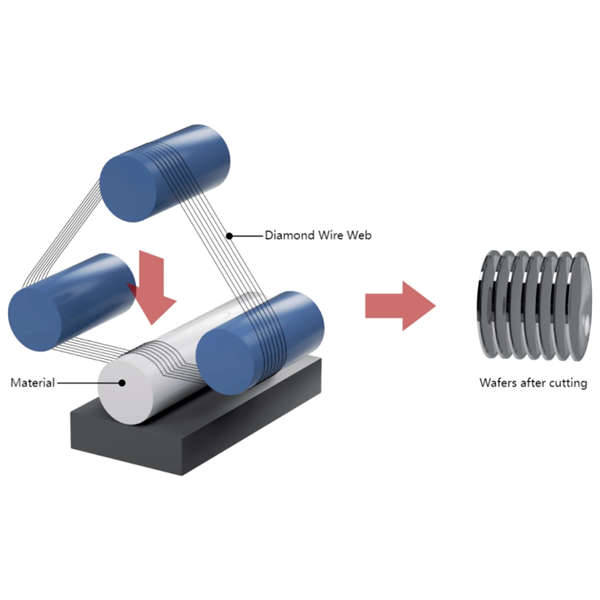

The Role of CNC Technology in Diamond Wire Saw Machines

Computer Numerical Control (CNC) technology has revolutionized the way diamond wire saw machines operate within factories. By integrating advanced software with hardware, CNC Diamond Wire Saw Machines achieve a level of precision unattainable through manual operations. These systems can cut through hard materials like stone, concrete, and metals with remarkable accuracy, making them indispensable in industries requiring high-quality cuts and finishes.

Advantages of Using CNC Diamond Wire Saws in Manufacturing

The adoption of CNC Diamond Wire Saw Machines in factories has led to numerous advantages over traditional cutting methods. One key benefit is the significant reduction in material waste due to precise cutting. Additionally, automation allows for continuous operation, increasing productivity and reducing labor costs. The versatility of these machines also enables them to handle a wide range of materials efficiently, further enhancing their value in diverse manufacturing environments.

Innovations in CNC Diamond Wire Saw Technology

To stay competitive, CNC Diamond Wire Saw Machine Factories continuously invest in research and development to improve their products. Recent innovations focus on enhancing machine durability, improving cutting speeds, and developing more sustainable cutting solutions. For instance, the introduction of eco-friendly coolants and the use of recycled materials in manufacturing processes reflect a commitment to environmental responsibility alongside technological advancement.

Customization Options for CNC Diamond Wire Saw Machines

Understanding that every factory has unique needs, CNC Diamond Wire Saw Machine Manufacturers offer customizable solutions tailored to specific requirements. This includes variations in machine size, cutting capacity, and software features designed to optimize performance for particular applications. Customization ensures that businesses can acquire equipment perfectly suited to their operational demands, thereby maximizing efficiency and profitability.

Maintenance and Support Services for CNC Diamond Wire Saw Machines

Given the complexity of CNC Diamond Wire Saw Machines, regular maintenance is crucial for ensuring optimal performance and longevity. Leading factories provide comprehensive support services, including on-site installation, training, and ongoing maintenance. Such services not only help in troubleshooting issues promptly but also contribute to the overall reliability of the machinery, thereby minimizing downtime and maintaining high production standards.

Future Prospects of CNC Diamond Wire Saw Machine Factories

Looking ahead, the future of CNC Diamond Wire Saw Machine Factories looks promising. As technology continues to evolve, we can expect even more sophisticated machines capable of handling complex tasks with greater ease. Moreover, the integration of artificial intelligence and IoT technologies promises to enhance automation levels, leading to smarter, more efficient manufacturing processes. With ongoing advancements, these factories will undoubtedly play a pivotal role in shaping the future of industrial cutting technologies.

Request for Quotation

报错: 未找到这个表单