The Releated Products of Cnc Diamond Wire Saw Machine

Cnc Diamond Wire Saw Machine

CNC Diamond Wire Saw Machine: Precision Cutting Redefined

In the realm of advanced cutting technologies, the CNC Diamond Wire Saw Machine stands as a beacon of precision and efficiency. This state-of-the-art equipment has revolutionized how materials are processed, offering unparalleled accuracy and speed. Whether you’re dealing with hard metals, stone, or composites, understanding the capabilities and benefits of a CNC Diamond Wire Saw Machine can significantly enhance your manufacturing processes.

The Core Components of a CNC Diamond Wire Saw Machine

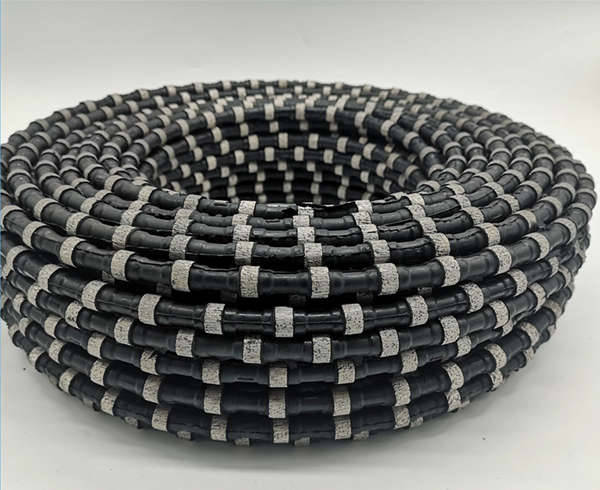

A CNC Diamond Wire Saw Machine consists of several critical components that work together to achieve precise cuts. At its heart is the computer numerical control (CNC) system, which ensures that every cut is made according to the digital blueprint provided. The diamond wire, embedded with industrial-grade diamonds, is the cutting tool that slices through materials with minimal effort. Supporting these elements are robust frame structures, motors for driving the wire, and tensioning systems to keep the wire taut and operational.

Applications of CNC Diamond Wire Saw Machines

From aerospace engineering to construction and stonemasonry, the applications of CNC Diamond Wire Saw Machines are vast. In the aerospace industry, they are used for cutting intricate parts from titanium and other high-strength alloys. For stonemasons, these machines offer a way to carve marble and granite into complex sculptures and architectural pieces. Additionally, they play a crucial role in solar panel manufacturing, where silicon wafers need to be cut with extreme precision.

Advantages of Using a CNC Diamond Wire Saw Machine

The CNC Diamond Wire Saw Machine offers numerous advantages over traditional cutting methods. One of the most significant is its ability to make clean, straight cuts with minimal material waste. This not only saves on raw materials but also reduces production costs. Another key advantage is the machine’s adaptability; it can easily switch between different types of materials and thicknesses, making it highly versatile. Furthermore, the automation aspect increases productivity by reducing the need for manual intervention, thereby improving safety and reducing labor costs.

Maintenance and Operational Considerations for CNC Diamond Wire Saw Machines

To ensure optimal performance and longevity, proper maintenance of a CNC Diamond Wire Saw Machine is essential. Regular checks on the wire’s condition, alignment of guides, and lubrication of moving parts are necessary. Operators must also be trained to handle the machine correctly and understand the importance of following safety protocols. Regular software updates and calibration checks help maintain the machine’s cutting precision over time.

Future Innovations in CNC Diamond Wire Saw Technology

As technology continues to advance, so too does the CNC Diamond Wire Saw Machine. Research is ongoing into developing even stronger diamond coatings for the wire, aiming to increase durability and cutting efficiency. There’s also a focus on integrating artificial intelligence (AI) into CNC systems, allowing for real-time adjustments based on material properties and wear patterns. These innovations promise to further enhance the capabilities of these machines, pushing the boundaries of what’s possible in precision cutting.

By investing in a CNC Diamond Wire Saw Machine, businesses can unlock new levels of efficiency, precision, and flexibility in their operations. Whether you’re looking to upgrade your current setup or exploring new manufacturing techniques, this powerful tool represents a significant step forward in achieving high-quality results with consistency and reliability.

Request for Quotation

报错: 未找到这个表单