The Releated Products of Customized Diamond Cutting Wire Saw

Customized Diamond Cutting Wire Saw

Customized Diamond Cutting Wire Saw: Precision Engineering for Advanced Material Processing

Customized Diamond Cutting Wire Saw: A New Era in Precision Cutting

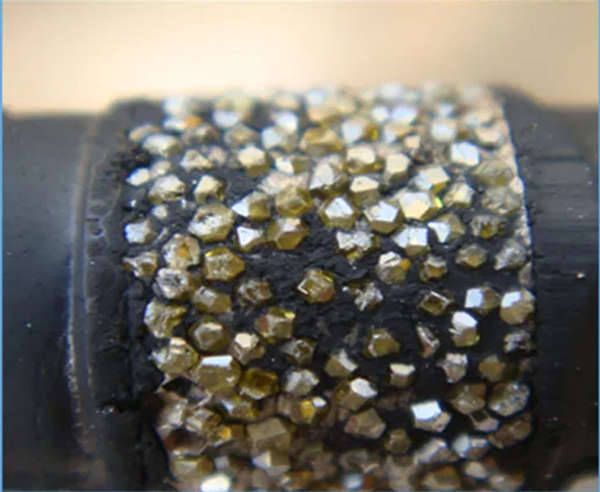

In the realm of industrial cutting technologies, the introduction of the customized diamond cutting wire saw has revolutionized how materials are processed. This innovative tool combines the strength of diamonds with the flexibility of wire, allowing for precise cuts through some of the hardest materials known to man. From construction to manufacturing, industries are witnessing a significant leap in efficiency and accuracy thanks to these advanced saws.

The core advantage of using a customized diamond cutting wire saw lies in its ability to adapt to various applications. Manufacturers can tailor the saw’s specifications, such as diameter, length, and diamond concentration, to meet specific project requirements. This customization ensures that whether you’re working on intricate gemstone carving or large-scale concrete demolition, there’s a diamond cutting wire saw designed specifically for the task.

Benefits of Using Customized Diamond Cutting Wire Saws

Enhanced Precision and Control

One of the most notable benefits of employing a customized diamond cutting wire saw is the unparalleled precision it offers. Unlike traditional blade saws, which can struggle with maintaining accuracy over time due to wear and tear, wire saws maintain their sharpness throughout their lifespan. This characteristic is particularly beneficial when dealing with thin cuts or when working on projects where dimensional accuracy is critical.

Versatility Across Multiple Industries

The customized diamond cutting wire saw finds applications across numerous sectors, including but not limited to mining, construction, and manufacturing. Its ability to cut through diverse materials—from metals and ceramics to stone and reinforced concrete—makes it an indispensable tool for professionals looking to tackle challenging projects efficiently.

Improved Safety Standards

Safety is paramount in any industrial setting, and the customized diamond cutting wire saw contributes significantly to this aspect. By reducing the need for manual intervention during the cutting process, these saws minimize the risk of accidents associated with handling heavy machinery. Additionally, they produce minimal dust and noise, creating a safer and more comfortable work environment.

Applications of Customized Diamond Cutting Wire Saws

Construction and Demolition Projects

In the construction industry, the customized diamond cutting wire saw is used extensively for demolition purposes, especially when precision is required to preserve surrounding structures. Its ability to make clean cuts without causing collateral damage makes it ideal for removing concrete slabs, bridge decks, and other large structures.

Gemstone Cutting and Polishing

For artisans and jewelers, the customized diamond cutting wire saw provides a means to achieve intricate designs with utmost precision. The fine wire embedded with microscopic diamonds allows for detailed work on precious stones, enhancing both beauty and value.

Industrial Manufacturing Processes

From cutting silicon wafers for semiconductor chips to slicing ceramic components for medical devices, the customized diamond cutting wire saw plays a crucial role in ensuring high-quality products across various manufacturing processes. Its adaptability to different materials and thicknesses ensures consistent performance and reliability.

Conclusion: Embracing the Future with Customized Diamond Cutting Wire Saws

As technology continues to evolve, so too does the demand for tools capable of delivering exceptional results with minimal effort. The customized diamond cutting wire saw stands out as a testament to human ingenuity, offering solutions that were once considered impossible. Whether your needs lie in the realm of artistry or heavy-duty industrial operations, investing in a diamond cutting wire saw customized to your specifications promises unparalleled performance and satisfaction.

Request for Quotation

报错: 未找到这个表单