The Releated Products of Cutting Ceramic With Circular Saw

Cutting Ceramic With Circular Saw

Cutting Ceramic With Circular Saw: Precision and Power

Cutting ceramic can be a challenging task, especially when precision and clean edges are required. However, with the right tools and techniques, even DIY enthusiasts can achieve professional results. One such tool that stands out for its versatility and power is the circular saw. While traditionally used for wood and metal, a circular saw can also be adapted for cutting ceramic with impressive accuracy and efficiency. In this article, we will explore how to cut ceramic using a circular saw, ensuring your projects are completed with finesse.

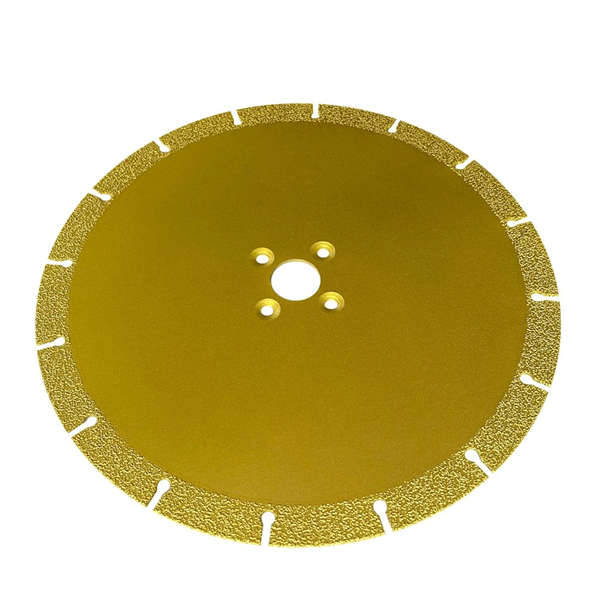

Selecting the Right Blade for Cutting Ceramic

The first step towards successful ceramic cutting with a circular saw is choosing the correct blade. A diamond blade is essential because it’s designed specifically for cutting through hard materials like ceramic tiles, porcelain, and stone. These blades feature a rim embedded with industrial diamonds that grind through the material rather than slicing it. For best results, opt for a wet-cut diamond blade, as water helps cool the blade and reduce dust during the cutting process.

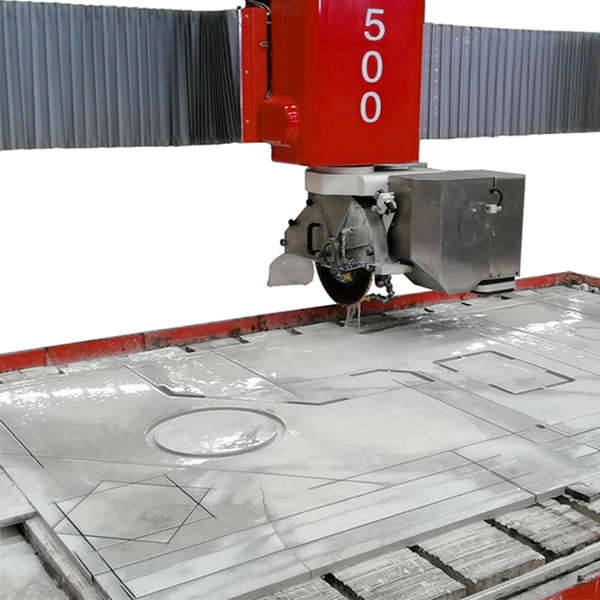

Preparing Your Workspace for Cutting Ceramic

Before you start cutting ceramic with your circular saw, ensure your workspace is properly set up. Lay down a thick plastic sheet or drop cloth to protect the surface and minimize mess. Position your workpiece on a sturdy, flat surface, and secure it using clamps or a vice to prevent movement during cutting. If possible, set up a water supply nearby to keep the blade cool and manage dust effectively.

Techniques for Cutting Ceramic Smoothly

Proper technique is crucial when cutting ceramic with a circular saw. Start by marking your cutting line clearly on the tile using a pencil or marker. Adjust the depth of the saw so that the blade just cuts through the thickness of the tile, avoiding unnecessary wear on the blade. Begin cutting slowly, applying steady pressure, and follow the marked line carefully. Maintain a consistent speed throughout the cut to ensure a smooth edge and prevent chipping.

Maintaining Safety While Cutting Ceramic

Safety should always be a top priority when working with power tools. Wear appropriate personal protective equipment (PPE) such as safety glasses, ear protection, and a dust mask to shield yourself from flying debris and harmful dust particles. Keep your hands away from the blade at all times, and never attempt to cut freehand. Always use a guide or fence to control the direction of the cut and maintain accuracy.

Troubleshooting Common Issues When Cutting Ceramic

Despite careful preparation and execution, you may encounter some issues while cutting ceramic with a circular saw. Chipping along the edges is a common problem, often caused by moving the blade too quickly or not maintaining a steady hand. To fix this, slow down your cutting pace and ensure the blade is aligned perfectly with your marked line. If you notice excessive heat buildup, stop cutting and allow the blade to cool down before continuing. This prevents damage to both the material and the tool.

Cleaning Up After Cutting Ceramic

After completing your cuts, it’s important to clean up properly. Dispose of the ceramic waste responsibly, following local regulations for hazardous materials. Clean your tools thoroughly to remove any residue or dust that could affect future performance. Store your circular saw and blades in a dry place, ideally covered or enclosed, to prevent rust and prolong their lifespan.

By following these guidelines, you’ll be well-equipped to tackle ceramic cutting projects with confidence using a circular saw. Remember, practice makes perfect, so don’t be discouraged if your first few attempts aren’t flawless. With time and experience, you’ll master the art of cutting ceramic efficiently and beautifully.

Request for Quotation

报错: 未找到这个表单