The Releated Products of Cutting Granite Blade

Cutting Granite Blade

Choosing the Right Cutting Granite Blade for Your Project

When it comes to working with granite, selecting the right cutting granite blade can make all the difference. Whether you’re a seasoned professional or a DIY enthusiast, understanding the nuances of these specialized tools is essential. A high-quality cutting granite blade not only ensures precision and efficiency but also extends the life of your equipment. Let’s delve into what makes a great cutting granite blade and how to choose one that best suits your needs.

Factors to Consider When Selecting a Cutting Granite Blade

Before making a purchase, consider several key factors that will influence the performance and longevity of your cutting granite blade. These include the size of the blade, its material composition, and the type of bond used. Larger blades generally offer deeper cuts, which can be beneficial for bigger projects. However, they also require more power from your saw. The material of the blade—typically diamond—is crucial because it determines the blade’s hardness and ability to cut through tough materials like granite.

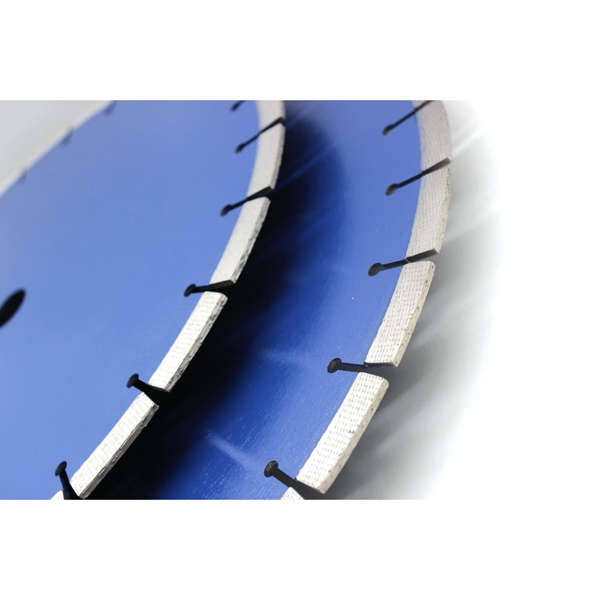

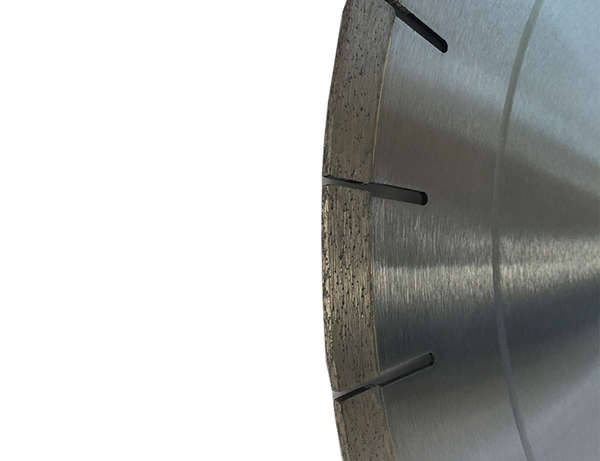

Diamond Segments: The Heart of a Cutting Granite Blade

Diamond segments are the cutting edges of a cutting granite blade, composed of synthetic diamonds embedded in a metal matrix. These segments wear down as the blade cuts, exposing new diamonds to continue the cutting process. The concentration and quality of diamonds, along with the segment height, play significant roles in determining the blade’s effectiveness on granite.

Maintenance and Care of Your Cutting Granite Blade

Proper maintenance is vital to ensure your cutting granite blade operates efficiently and has a long lifespan. After each use, clean the blade thoroughly to remove any debris that could interfere with future cuts. Store your blade in a dry place away from extreme temperatures. Regular inspections for damage such as cracks or chips are also important. Addressing issues promptly can prevent further damage and potential accidents.

Sharpening Your Cutting Granite Blade

While some wear is normal, dull blades can lead to overheating and decreased performance. Sharpening your cutting granite blade periodically can help maintain its cutting efficiency. Professional sharpening services are available, but if you prefer doing it yourself, there are specific tools designed for this purpose. Always follow manufacturer guidelines to avoid damaging the blade during the sharpening process.

Applications of Cutting Granite Blades

Cutting granite blades are versatile tools used across various industries, including construction, countertop fabrication, and landscaping. In construction, they are indispensable for creating precise cuts in granite slabs used for flooring and facades. Countertop fabricators rely on them to produce custom sizes and shapes for kitchens and bathrooms. Landscapers often use these blades for shaping stone elements in outdoor designs, ensuring clean, professional results.

Specialized Blades for Unique Projects

For unique or specialized projects, such as intricate designs or curved edges, specialized cutting granite blades are available. These blades feature different configurations and diamond segment layouts optimized for specific tasks. When tackling complex projects, investing in these specialized tools can greatly enhance the final product’s quality and reduce the time required for completion.

Conclusion

Investing in a high-quality cutting granite blade is a smart decision for anyone working with granite. By considering factors like blade size, diamond segment quality, and proper maintenance practices, you can ensure optimal performance and longevity. Whether you’re tackling a large-scale construction project or a small DIY job, having the right tool makes all the difference. Remember, regular care and occasional sharpening will keep your cutting granite blade performing at its best, saving you both time and money in the long run.

Request for Quotation

报错: 未找到这个表单