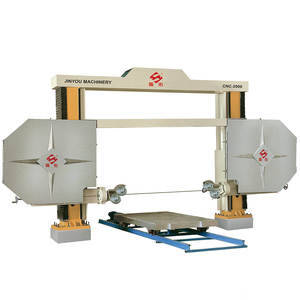

The Releated Products of Diamond Cut Grinding Wheel

Diamond Cut Grinding Wheel

Understanding Diamond Cut Grinding Wheels: Precision in Every Turn

In the realm of industrial cutting and grinding, precision and durability are paramount. This is where diamond cut grinding wheels shine, offering unparalleled performance and longevity. Whether you’re dealing with hard metals, ceramics, or composite materials, these specialized tools have become indispensable in modern manufacturing processes. Let’s delve deeper into what makes them so effective and explore their applications across various industries.

Diamond Cut Grinding Wheel Materials and Construction

Diamond cut grinding wheels are meticulously engineered to deliver superior results. At their core, they consist of a rigid base made from materials such as steel or aluminum. Embedded into this base are thousands of diamond particles, which serve as the cutting edges. These diamonds can either be electroplated onto the surface or sintered for enhanced bonding strength. The choice between electroplating and sintering depends largely on the specific application and desired longevity of the wheel.

Applications of Diamond Cut Grinding Wheels

The versatility of diamond cut grinding wheels is one of their most significant advantages. They find extensive use in industries ranging from automotive manufacturing to aerospace engineering. In construction, they are invaluable for cutting through concrete and asphalt with minimal effort. For jewelers and artisans, these wheels provide the precision needed for intricate designs on precious stones and metals. By adapting to diverse needs, diamond cut grinding wheels ensure efficiency and accuracy across a broad spectrum of tasks.

Advantages of Using Diamond Cut Grinding Wheels

When it comes to choosing the right tool for the job, understanding the benefits of diamond cut grinding wheels can help make an informed decision. Firstly, their hardness allows them to maintain sharpness even when working with extremely hard materials. This translates into longer service intervals and reduced downtime for maintenance. Additionally, the high thermal conductivity of diamond helps dissipate heat quickly, preventing damage to both the workpiece and the wheel itself. Lastly, because they require less force to operate compared to conventional wheels, operators experience less fatigue during prolonged use.

Maintenance and Care of Diamond Cut Grinding Wheels

To ensure optimal performance and extend the life of your diamond cut grinding wheel, proper care and maintenance are essential. Regular inspection should be performed to check for any signs of wear or damage. Cleaning the wheel thoroughly after each use removes debris that could interfere with its operation. If necessary, reconditioning services offered by manufacturers can restore the wheel’s cutting efficiency. By following these guidelines, users can maximize the lifespan and effectiveness of their diamond cut grinding wheels.

Choosing the Right Diamond Cut Grinding Wheel for Your Needs

Selecting the appropriate diamond cut grinding wheel involves considering several factors, including the material being worked on, the required finish quality, and operational conditions. For softer materials, a wheel with a softer bond is preferable as it will allow for better self-sharpening action. Conversely, harder materials necessitate a stronger bond to prevent premature wear. Tailoring the selection process to match specific requirements ensures that the chosen wheel performs optimally in its intended application.

Future Innovations in Diamond Cut Grinding Technology

As technology advances, so too does the design and functionality of diamond cut grinding wheels. Research is ongoing into developing new bonding agents that enhance adhesion while reducing environmental impact. Additionally, efforts are being made to improve the manufacturing process, aiming for higher precision and consistency in the placement of diamond particles. These innovations promise not only improved performance but also greater sustainability, aligning with global initiatives towards greener manufacturing practices.

By embracing the capabilities of diamond cut grinding wheels, industries worldwide stand to benefit from increased productivity, cost savings, and superior product quality. As we continue to innovate within this field, the future looks bright for those who rely on these powerful tools to get the job done right every time.

Request for Quotation

报错: 未找到这个表单