The Releated Products of Diamond Cutting Tools For Stone

Diamond Cutting Tools For Stone

Table of Contents

Diamond Cutting Tools for Stone: Precision and Durability

Diamond cutting tools for stone have revolutionized the industry by providing unparalleled precision and durability. These tools are essential in various applications, from construction to artistry, where accuracy and efficiency are paramount. By leveraging the natural hardness of diamonds, these tools can cut through even the toughest materials with ease.

Advantages of Using Diamond Cutting Tools for Stone

The primary advantage of diamond cutting tools for stone lies in their ability to maintain sharpness over extended periods. Unlike traditional metal blades, which can dull quickly when faced with abrasive materials like granite or marble, diamond tools retain their edge longer. This durability translates into reduced downtime for maintenance and replacement, making them cost-effective solutions for high-volume projects.

Moreover, the use of diamond cutting tools for stone ensures cleaner cuts with minimal chipping or cracking. This characteristic is particularly beneficial when working with delicate stones that require precise shaping without compromising structural integrity.

Types of Diamond Cutting Tools for Stone

A wide range of diamond cutting tools for stone is available on the market, each designed to meet specific needs within the industry. Common types include:

– Segmented Blades: Ideal for cutting concrete, brick, and softer stones, segmented blades feature a series of diamond segments welded around the perimeter of the blade.

– Continuous Rim Blades: Perfect for finer materials such as marble and granite, continuous rim blades offer smoother cuts due to their solid diamond coating around the entire edge.

– Core Drills: Used primarily for creating holes in stone surfaces, core drills come in various sizes depending on the required diameter of the hole.

Each type of tool offers unique benefits suited to different tasks, ensuring there’s a solution for every application involving stone.

Selection Criteria for Diamond Cutting Tools for Stone

Choosing the right diamond cutting tool for stone depends on several factors, including the material being cut, the desired finish, and the project scale. For instance, harder stones may necessitate tools with higher diamond concentrations to achieve efficient cutting performance.

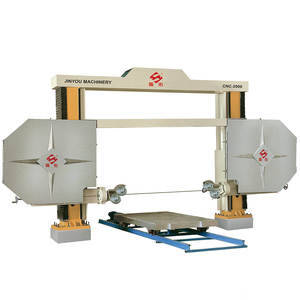

Other considerations include the size and power of the equipment used to operate these tools. Larger projects often require more robust machinery capable of handling heavier-duty blades. Additionally, safety features such as dust collection systems become increasingly important as project sizes grow.

Maintenance and Care of Diamond Cutting Tools for Stone

Proper maintenance plays a crucial role in extending the lifespan of diamond cutting tools for stone. Regular cleaning helps prevent buildup of debris that could otherwise interfere with cutting efficiency. It’s also advisable to inspect tools periodically for signs of wear or damage, replacing them promptly to avoid accidents or subpar results.

Following manufacturer guidelines regarding operating temperatures and speeds is essential for maximizing performance while minimizing wear. By adhering to these recommendations, users can ensure their investment remains productive throughout its service life.

Innovations in Diamond Cutting Tools for Stone

As technology advances, so too does the design and functionality of diamond cutting tools for stone. Recent innovations focus on enhancing both the cutting capabilities and user experience. For example, some manufacturers now offer laser-welded diamond segments that provide superior bonding strength compared to traditional methods.

Furthermore, advancements in diamond synthesis have led to the creation of synthetic diamonds that rival natural counterparts in terms of hardness and durability. These developments promise to further improve the effectiveness of diamond cutting tools for stone, setting new standards for performance across industries.

By staying abreast of these trends, professionals can leverage state-of-the-art tools to achieve exceptional results in their work with stone.

Request for Quotation

报错: 未找到这个表单