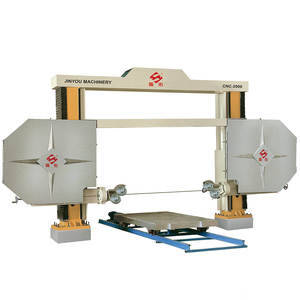

The Releated Products of Diamond Rock Cutter

Diamond Rock Cutter

Diamond Rock Cutter: Precision and Power in Modern Mining

In the realm of mining and construction, precision and efficiency are paramount. This is where the diamond rock cutter emerges as a game-changer. By harnessing the natural hardness of diamonds, these tools deliver unmatched performance in cutting through the toughest materials. Let’s explore the features, applications, and benefits of diamond rock cutters, which have become indispensable in various industries.

The Unmatched Hardness of Diamond Rock Cutters

The core strength of a diamond rock cutter lies in its composition. These tools are embedded with synthetic or natural diamonds, which are among the hardest materials known to man. When combined with robust steel structures, they form a tool capable of cutting through rock, concrete, and even reinforced materials with ease. The durability of diamonds ensures that the cutter remains sharp for extended periods, reducing downtime and maintenance costs.

Applications of Diamond Rock Cutters in Construction

From road construction to bridge building, diamond rock cutters play a crucial role in shaping our infrastructure. They can effortlessly slice through asphalt and concrete, making them ideal for creating precise cuts during renovations or new constructions. Additionally, their ability to work without producing significant heat means that they can be used safely around existing structures without risk of damage due to thermal expansion.

How Diamond Rock Cutters Enhance Efficiency

One of the key advantages of using a diamond rock cutter is its contribution to operational efficiency. These tools allow for faster cutting speeds compared to traditional methods, thereby reducing project timelines. Moreover, the clean and accurate cuts produced by diamond blades minimize material waste, leading to cost savings for projects of all sizes. Whether it’s cutting granite countertops or drilling through bedrock, these cutters ensure that tasks are completed swiftly and accurately.

Safety Features of Diamond Rock Cutters

Safety is non-negotiable when working with heavy machinery and powerful tools like diamond rock cutters. Manufacturers incorporate several safety features into these devices to protect operators and bystanders. Water-fed systems help control dust and reduce friction, while ergonomic handles provide better grip and control. Regular inspections and adherence to manufacturer guidelines are essential to maintaining optimal performance and ensuring the safety of everyone involved.

Environmental Impact of Using Diamond Rock Cutters

While often overlooked, the environmental impact of construction and mining activities is significant. Diamond rock cutters contribute positively here as well. Their ability to make precise cuts reduces the need for additional material removal, thus lowering overall waste production. Furthermore, the reduced noise levels associated with diamond cutting technology make it a more environmentally friendly option compared to traditional cutting methods.

Future Innovations in Diamond Rock Cutting Technology

As technology advances, so does the potential of diamond rock cutters. Research is ongoing to develop even harder diamond compounds and more durable bonding agents. This will likely lead to tools that are not only more efficient but also longer-lasting. Additionally, advancements in automation could see diamond cutters integrated into robotic systems, further enhancing productivity and safety in industrial settings.

The diamond rock cutter represents a pinnacle of engineering innovation, blending natural strength with human ingenuity. As industries continue to evolve, these tools will undoubtedly play a pivotal role in shaping the future of construction and mining operations worldwide.

Request for Quotation

报错: 未找到这个表单