The Releated Products of Diamond Rope Saw

Diamond Rope Saw

Table of Contents

Diamond Rope Saw: A Revolutionary Tool for Precise Cutting

In the world of industrial cutting, precision and efficiency are paramount. One tool that has significantly transformed the industry is the diamond rope saw. This advanced technology offers unparalleled accuracy and speed, making it indispensable in various applications from quarrying to construction. Below, we explore the features, benefits, and uses of diamond rope saws, highlighting why they are becoming the go-to solution for professionals worldwide.

Diamond Rope Saw Technology

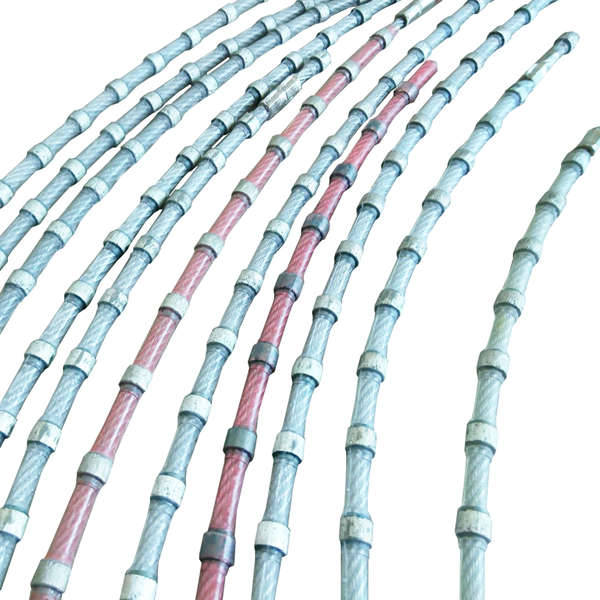

The diamond rope saw is a specialized cutting tool designed for slicing through hard materials like stone, concrete, and reinforced metals. Its core component is a thin, flexible cable embedded with diamond grains, which act as cutting edges. These diamonds are typically synthetic and are bonded to the wire using metal alloys. The diamond rope saw operates by oscillating back and forth at high speeds, allowing it to cut precisely and smoothly through even the toughest materials.

Advantages of Using a Diamond Rope Saw

There are numerous reasons why the diamond rope saw stands out among other cutting tools. Firstly, its ability to make clean, straight cuts without producing excessive heat or dust makes it ideal for environments where safety and cleanliness are critical. Additionally, the diamond rope saw can operate continuously without overheating, ensuring consistent performance over extended periods. This reliability is particularly beneficial in large-scale projects where downtime can be costly.

Applications of Diamond Rope Saws

The versatility of the diamond rope saw allows it to excel in a wide range of applications. In quarries, these saws are used to extract blocks of stone with minimal waste and damage to the surrounding rock. In construction, they facilitate the removal of concrete slabs and the cutting of openings in walls. For restoration projects, the diamond rope saw provides a precise method for removing old structures without affecting nearby historical elements.

Maintenance and Care of Diamond Rope Saws

To ensure optimal performance and longevity, proper maintenance of the diamond rope saw is essential. Regular inspections should be conducted to check for wear and tear on the diamond-impregnated wire. Lubrication of moving parts and cleaning of the saw after each use help prevent corrosion and extend its service life. Following manufacturer guidelines for storage and handling also contributes to maintaining the integrity of the diamond rope saw.

Environmental Impact of Diamond Rope Saws

One often-overlooked benefit of using a diamond rope saw is its environmental impact. Compared to traditional methods such as blasting, this technology generates less noise pollution and produces fewer harmful emissions. Moreover, the precision of the cut reduces material waste, contributing to more sustainable practices in industries like mining and construction. By choosing a diamond rope saw, companies can demonstrate their commitment to reducing their carbon footprint while improving operational efficiency.

Future Innovations in Diamond Rope Saw Technology

As technology continues to advance, so too does the development of the diamond rope saw. Research is ongoing into new materials and techniques that could further enhance the capabilities of these saws. Potential improvements include longer-lasting diamond coatings, more efficient cooling systems, and smarter control mechanisms that adapt to different cutting conditions. These innovations promise to make the diamond rope saw even more effective and versatile in the years to come.

By investing in a diamond rope saw, businesses can achieve higher productivity, better quality results, and improved safety standards. As the technology evolves, it will undoubtedly continue to play a crucial role in shaping the future of industrial cutting.

Request for Quotation

报错: 未找到这个表单