The Releated Products of Diamond Rope Saw Manufacturers

Diamond Rope Saw Manufacturers

Table of Contents

Diamond Rope Saw Manufacturers: Pioneering Precision in Cutting Technology

In the realm of industrial cutting solutions, diamond rope saws have emerged as a powerful tool for precision and efficiency. These specialized tools, crafted by leading diamond rope saw manufacturers, are revolutionizing industries from construction to mining and beyond. This article delves into the world of these innovative manufacturers, exploring their contributions to modern technology and the benefits they bring to various sectors.

The Evolution of Diamond Rope Saws

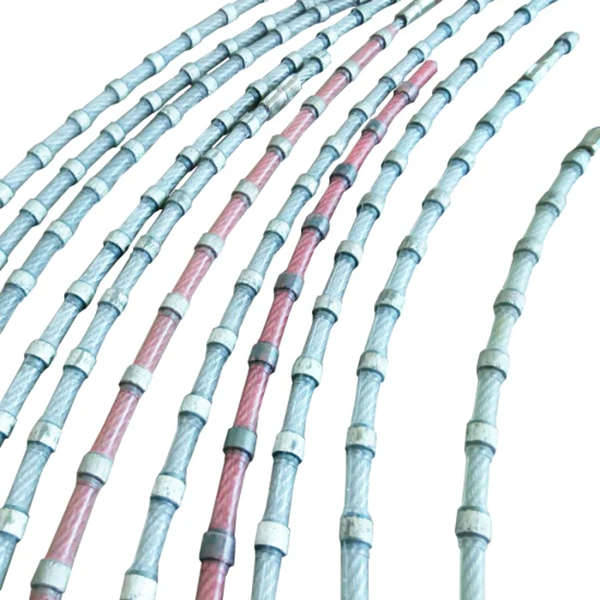

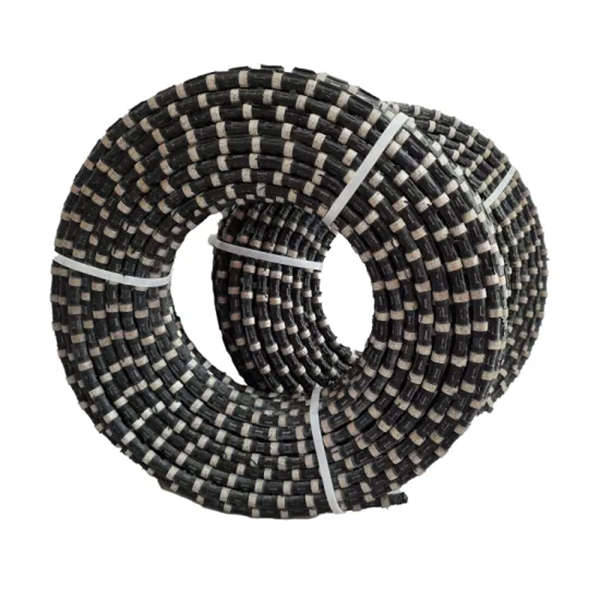

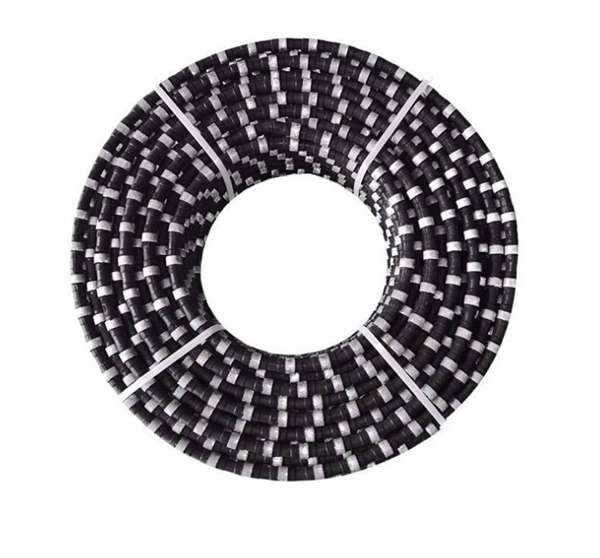

The journey of diamond rope saw manufacturers begins with the evolution of cutting technology. Initially used in the stone quarrying industry, diamond rope saws have evolved significantly over the years. Today’s advanced designs incorporate high-strength steel cables embedded with synthetic diamonds, ensuring unparalleled cutting performance across a range of materials. Diamond rope saw manufacturers continue to innovate, pushing the boundaries of what these tools can achieve.

Innovative Techniques by Diamond Rope Saw Manufacturers

To stay ahead in a competitive market, diamond rope saw manufacturers invest heavily in research and development. They explore new materials, manufacturing processes, and design configurations to enhance durability and cutting efficiency. Techniques such as laser welding and electroplating are commonly employed to attach diamond segments to the rope, a process critical for maintaining the saw’s integrity under extreme conditions.

Custom Solutions from Diamond Rope Saw Manufacturers

Recognizing that every project has unique requirements, top diamond rope saw manufacturers offer custom solutions tailored to specific applications. Whether it’s cutting through reinforced concrete or extracting precious stones from hard rock, these manufacturers can provide customized saws designed to meet the exact needs of their clients. This flexibility is crucial in ensuring optimal performance and cost-effectiveness in diverse industrial settings.

Sustainability Efforts by Diamond Rope Saw Manufacturers

As environmental concerns become increasingly important, diamond rope saw manufacturers are also focusing on sustainability. Many are adopting practices that reduce waste and lower the carbon footprint of their operations. For instance, recycling used diamond segments and optimizing production processes to minimize energy consumption are steps being taken by conscientious manufacturers. These efforts not only benefit the environment but also contribute to long-term business sustainability.

Global Reach of Diamond Rope Saw Manufacturers

The impact of diamond rope saw manufacturers extends far beyond their local markets. With a global network of distributors and customers, these companies are contributing to projects around the world. From skyscraper construction in urban centers to remote mining operations, their products are integral to numerous industries. This global reach underscores the importance of maintaining high standards in manufacturing and customer service.

Future Prospects for Diamond Rope Saw Manufacturers

Looking ahead, the future of diamond rope saw manufacturers seems bright. Advancements in material science and automation technologies promise further improvements in product quality and production efficiency. Moreover, as industries adopt more sustainable practices, there will be increased demand for eco-friendly cutting solutions. Diamond rope saw manufacturers who can adapt and innovate will undoubtedly play a key role in shaping the future of industrial cutting.

By focusing on innovation, customization, sustainability, and global outreach, diamond rope saw manufacturers are setting new benchmarks in their field. Their contributions are not just technological; they are also helping to build a more efficient, sustainable, and interconnected world. As we move forward, the importance of these manufacturers in driving progress cannot be overstated.

Request for Quotation

报错: 未找到这个表单