The Releated Products of Diamond Rubber Wire Saw

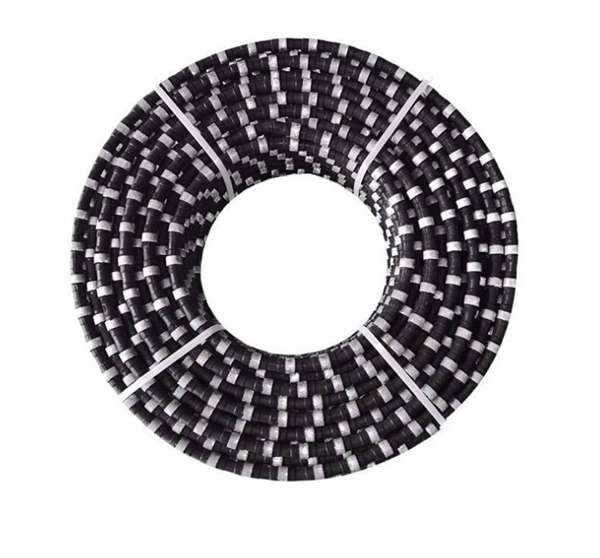

Diamond Rubber Wire Saw

Diamond Rubber Wire Saw: Precision Cutting for Tough Materials

In the realm of industrial cutting tools, the Diamond Rubber Wire Saw has emerged as a versatile and efficient solution for slicing through dense materials. From construction to mining operations, this specialized tool offers unparalleled precision and durability. Let’s delve into the specifics of what makes the diamond rubber wire saw a standout choice in the industry.

Advantages of Using a Diamond Rubber Wire Saw

The Diamond Rubber Wire Saw boasts several advantages over traditional cutting methods. Its design incorporates a thin wire embedded with diamond grains, allowing for precise cuts even in hard-to-reach areas. This makes it ideal for applications requiring accuracy and minimal material loss. Additionally, the rubber coating on the wire reduces vibration, enhancing operator comfort and control during use.

Applications of the Diamond Rubber Wire Saw

From quarrying granite and marble to cutting concrete structures, the Diamond Rubber Wire Saw finds its application across various sectors. Its ability to cut continuously without overheating is particularly beneficial in continuous operation scenarios. Whether it’s in bridge demolition or tunnel construction, this tool ensures clean, straight cuts every time.

How Does a Diamond Rubber Wire Saw Work?

Understanding how the Diamond Rubber Wire Saw operates provides insight into its efficiency and effectiveness. Essentially, the saw consists of a looped wire coated with synthetic diamonds that rotate at high speeds. When pressed against the material, these diamonds grind away at the surface, creating a smooth cut. The rubber coating helps maintain tension and stability throughout the process, preventing slippage and ensuring safety.

Maintenance and Care of Your Diamond Rubber Wire Saw

Proper maintenance is crucial for extending the lifespan of your Diamond Rubber Wire Saw. Regular inspection of the wire for wear and tear is essential, as is cleaning the saw after each use to remove debris. Lubricating moving parts and storing the tool in a dry place can also prevent corrosion and ensure optimal performance over time.

Choosing the Right Diamond Rubber Wire Saw

Selecting the appropriate Diamond Rubber Wire Saw depends on several factors including the type of material being cut and the specific requirements of your project. Factors such as wire thickness, diamond concentration, and loop length all play a role in determining the best tool for the job. Consulting with a professional or conducting thorough research can help you make an informed decision.

Safety Precautions When Using a Diamond Rubber Wire Saw

Safety must always be a priority when operating any industrial machinery, including the Diamond Rubber Wire Saw. Always wear protective gear such as goggles, gloves, and ear protection. Ensure the work area is well-lit and free from obstructions. Follow manufacturer guidelines closely and undergo proper training if necessary to avoid accidents.

In conclusion, the Diamond Rubber Wire Saw represents a significant advancement in cutting technology, offering users a powerful combination of precision, durability, and ease-of-use. By understanding its features, applications, and proper usage, operators can harness its full potential, contributing to more efficient and safer work environments.

Request for Quotation

报错: 未找到这个表单