The Releated Products of Diamond Wire Coping Saw

Diamond Wire Coping Saw

Diamond Wire Coping Saw: Precision Cutting for Modern Applications

In the realm of advanced cutting technologies, the diamond wire coping saw has emerged as a game-changer. This specialized tool offers unparalleled precision and efficiency, making it indispensable across various industries. From construction to manufacturing, understanding the capabilities and benefits of diamond wire coping saws can significantly enhance project outcomes.

What Is a Diamond Wire Coping Saw?

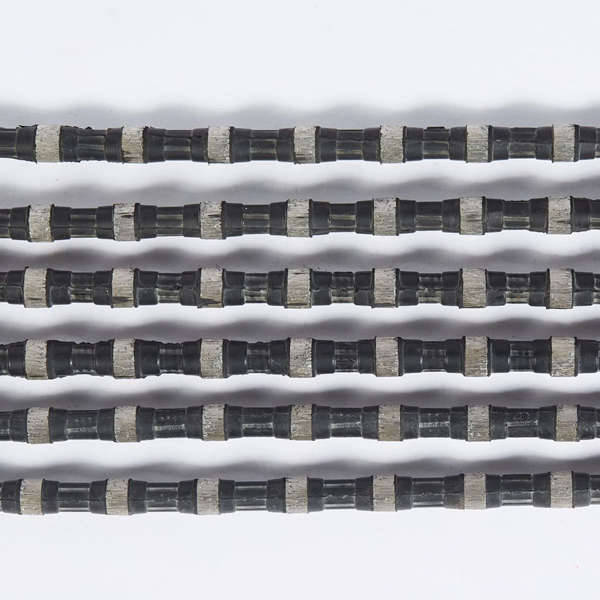

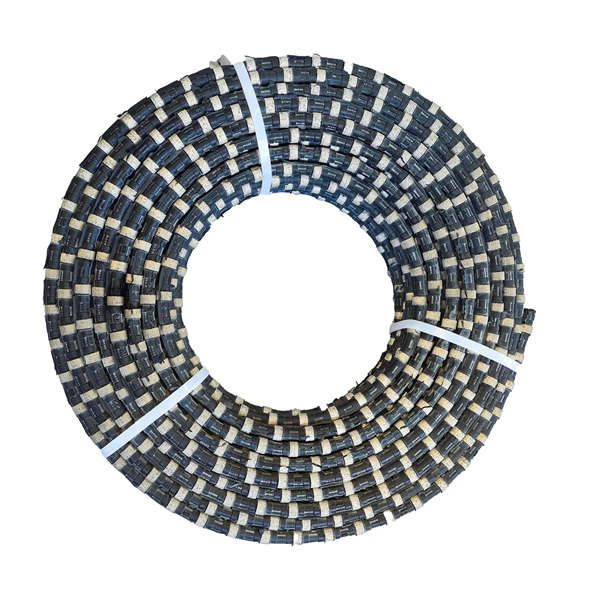

A diamond wire coping saw is a sophisticated piece of machinery designed for precise cutting applications. It utilizes a thin, flexible wire embedded with industrial diamonds. These diamonds act as abrasive cutting edges, allowing the saw to slice through hard materials like stone, concrete, and reinforced metals with minimal effort.

How Does a Diamond Wire Coping Saw Work?

The working principle of a diamond wire coping saw revolves around the continuous motion of the wire. Motors drive the wire at high speeds, ensuring that the diamond-impregnated segments continuously abrade the material being cut. This method ensures clean, straight cuts with minimal material loss, ideal for intricate designs and tight spaces.

Benefits of Using a Diamond Wire Coping Saw

Precision and Accuracy

One of the primary advantages of using a diamond wire coping saw is its ability to achieve highly precise cuts. The thinness of the wire allows for detailed work, making it perfect for creating complex shapes and patterns without compromising structural integrity.

Versatility

The diamond wire coping saw is incredibly versatile, capable of handling a wide range of materials. Whether you’re working with granite, marble, or steel, this tool can deliver consistent results with minimal wear and tear on the wire itself.

Cost-Effectiveness

Despite its advanced features, the diamond wire coping saw can be more cost-effective than traditional cutting methods over time. Its durability means fewer replacements, while its efficiency reduces labor costs associated with longer cutting times.

Applications of Diamond Wire Coping Saws

From architectural projects requiring custom stone work to industrial settings where precision is paramount, diamond wire coping saws find their place across diverse sectors. They are particularly useful in:

– Stone carving and sculpture

– Fabrication of countertops and tiles

– Repair and restoration of historic buildings

Maintenance and Care of Diamond Wire Coping Saws

To ensure optimal performance and longevity, proper maintenance of your diamond wire coping saw is crucial. Regular cleaning, inspection, and replacement of worn parts are essential practices. Additionally, using the correct wire type for specific materials can prevent premature wear and tear.

Conclusion

As technology continues to advance, tools like the diamond wire coping saw play a pivotal role in pushing the boundaries of what’s possible in cutting and shaping materials. By investing in such equipment, professionals can elevate their craft, achieving levels of precision and efficiency previously unattainable. Whether you’re a seasoned artisan or a large-scale manufacturer, the benefits of incorporating a diamond wire coping saw into your workflow are undeniable.

Request for Quotation

报错: 未找到这个表单