The Releated Products of Diamond Wire Rock Cutting Machine

Diamond Wire Rock Cutting Machine

Table of Contents

Diamond Wire Rock Cutting Machine: Precision and Efficiency in Stone Extraction

In the dynamic landscape of modern construction and mining, the Diamond Wire Rock Cutting Machine has emerged as a game-changer. This advanced machinery combines cutting-edge technology with unparalleled precision to deliver efficient and clean cuts through even the hardest rocks. Whether it’s granite, marble, or limestone, these machines offer a level of control and accuracy previously unattainable with traditional methods.

Diamond Wire Rock Cutting Machine Technology

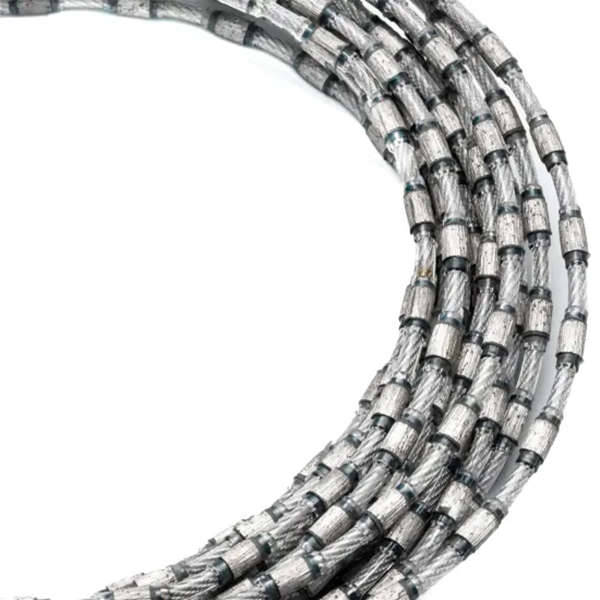

Understanding the core technology behind the Diamond Wire Rock Cutting Machine is crucial for appreciating its capabilities. At its heart lies a thin wire embedded with diamond particles, which is continuously fed through the material to be cut. The wire, typically made of steel, moves at high speeds, ensuring smooth and precise cuts. This method not only reduces waste but also allows for complex shapes and designs to be carved out effortlessly.

The continuous loop design of the wire ensures consistent pressure and speed, resulting in cleaner edges and minimal chipping. Moreover, the ability to adjust the tension and speed of the wire makes the Diamond Wire Rock Cutting Machine versatile, capable of tackling various types of stone with ease.

Benefits of Using a Diamond Wire Rock Cutting Machine

The adoption of Diamond Wire Rock Cutting Machines brings numerous benefits to industries relying heavily on stone extraction and processing. One of the most significant advantages is the reduction in noise pollution compared to traditional blasting techniques. Additionally, these machines produce less dust, making them environmentally friendlier and safer for workers.

Another key benefit is the substantial increase in productivity. By using a Diamond Wire Rock Cutting Machine, quarries can operate more efficiently, cutting through stone faster and with greater precision. This leads to higher yields and reduced downtime, ultimately translating into cost savings for businesses.

Maintenance and Operational Costs of Diamond Wire Rock Cutting Machine

While investing in a Diamond Wire Rock Cutting Machine represents a significant upfront cost, the long-term operational costs are relatively low. Regular maintenance primarily involves checking the condition of the diamond wire and ensuring the machine’s components are functioning correctly. Unlike other cutting methods that require frequent replacement of blades or bits, the diamond wire has a longer lifespan, reducing maintenance frequency and costs.

Furthermore, the efficiency gains from using a Diamond Wire Rock Cutting Machine often outweigh initial expenses, making it a cost-effective solution over time. The reduction in waste material also contributes positively to the bottom line by minimizing raw material costs.

Safety Features in Diamond Wire Rock Cutting Machine

Safety is paramount in any industrial setting, and Diamond Wire Rock Cutting Machines incorporate several features to ensure operator safety. These include automatic shut-off mechanisms in case of malfunction, ergonomic controls, and protective barriers around moving parts. Training operators thoroughly on the proper use and handling of the machine is essential for maintaining a safe working environment.

Advanced models of the Diamond Wire Rock Cutting Machine may also come equipped with real-time monitoring systems that alert users to potential issues, further enhancing workplace safety.

Applications of Diamond Wire Rock Cutting Machine

From architectural projects requiring intricate stone carvings to large-scale mining operations, the applications of Diamond Wire Rock Cutting Machines are vast. In construction, these machines are used for creating precise stone slabs and tiles, contributing to the aesthetic appeal of buildings. In mining, they facilitate the extraction of valuable minerals from rock formations with minimal damage to the surrounding area.

The versatility of the Diamond Wire Rock Cutting Machine makes it indispensable across multiple sectors, driving innovation and improving industry standards worldwide.

By integrating Diamond Wire Rock Cutting Machines into their operations, companies can achieve higher levels of productivity, safety, and sustainability. As technology continues to evolve, we can expect these machines to become even more sophisticated, further pushing the boundaries of what’s possible in stone cutting and processing.

Request for Quotation

报错: 未找到这个表单