The Releated Products of Diamond Wire Saw Cutting Granite

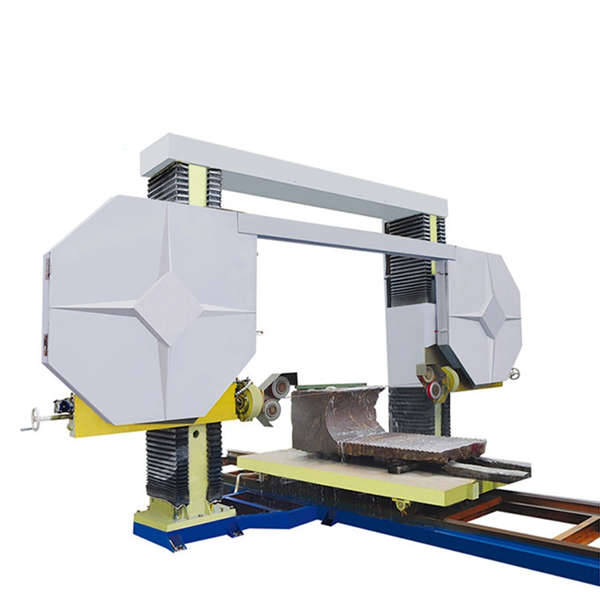

Diamond Wire Saw Cutting Granite

Diamond Wire Saw: Precision in Granite Cutting

In the realm of stone cutting, precision and efficiency are paramount. One technology that has revolutionized the industry is diamond wire saw cutting. Specifically designed for granite, this method offers unparalleled accuracy and speed. Whether it’s for construction projects or artistic endeavors, diamond wire saws have become indispensable tools. Let’s delve into how they work and why they’re so effective.

Diamond Wire Saw Cutting Granite: Efficiency and Speed

The core principle behind diamond wire saw cutting granite lies in its design. A thin metal cable embedded with diamond grains rotates rapidly, slicing through even the hardest materials like granite with ease. This process is not only faster than traditional methods but also reduces noise pollution and dust emissions significantly. For large-scale projects requiring rapid turnaround times, the benefits are clear—increased productivity without compromising on quality.

Benefits of Using Diamond Wire Saws for Granite

When considering the use of diamond wire saws for granite, several advantages come to light. Firstly, the flexibility of the wire allows for complex cuts that would be challenging or impossible with other tools. Additionally, because the wire can be as long as necessary, it can cut slabs of any size. This versatility makes it ideal for both small workshops and large quarries alike. Moreover, minimal material loss during cutting translates into higher yields and lower costs over time.

Applications in Modern Construction and Design

From skyscrapers to sculptures, diamond wire saw cutting granite plays a crucial role in modern architecture and art. Its ability to achieve clean, precise cuts means architects and designers can push the boundaries of creativity without worrying about practical limitations. In construction, it enables the creation of intricate facades and unique interior designs, enhancing aesthetic appeal while maintaining structural integrity.

Maintenance and Longevity of Diamond Wire Saws

To ensure optimal performance and longevity, proper maintenance of diamond wire saws is essential. Regular inspections help identify wear and tear early, preventing costly downtime. Lubrication of moving parts and timely replacement of worn segments are key practices. By following these guidelines, users can extend the life span of their equipment, ensuring consistent performance and reducing operational costs.

Environmental Impact of Diamond Wire Saw Technology

One often overlooked aspect of diamond wire saw cutting granite is its environmental footprint. Compared to traditional cutting techniques, this method generates less waste and consumes less energy. The reduction in noise levels also contributes positively to surrounding communities. As sustainability becomes increasingly important across industries, adopting such eco-friendly technologies can make a significant difference.

Training and Safety Considerations

While diamond wire saw cutting granite offers numerous benefits, safety remains paramount. Operators must receive thorough training on the proper use and handling of these machines. Safety protocols including the use of personal protective equipment (PPE) and adherence to manufacturer guidelines are non-negotiable. Proper training ensures not only worker safety but also maximizes the efficiency and effectiveness of the cutting process.

Diamond wire saw technology continues to evolve, offering new possibilities for those working with granite. From enhancing project timelines to improving safety standards, the advantages are numerous. As we look toward the future, innovations in this field promise even more efficient and sustainable solutions for granite cutting applications.

Request for Quotation

报错: 未找到这个表单