The Releated Products of Diamond Wire Saw For Granite Quarrying

Diamond Wire Saw For Granite Quarrying

Table of Contents

Diamond Wire Saw for Granite Quarrying: Precision and Efficiency in Stone Extraction

In the world of stone extraction and processing, efficiency and precision are paramount. Among the various tools used today, the diamond wire saw stands out as a revolutionary technology that has transformed granite quarrying. This article delves into the benefits, applications, and advancements of diamond wire saws specifically designed for granite quarrying, highlighting how they enhance productivity and sustainability.

The Evolution of Diamond Wire Saws in Granite Quarrying

The journey of diamond wire saw technology began several decades ago but has seen significant advancements in recent years. Initially developed to cut softer stones, improvements in diamond segment technology and wire strength have made these saws indispensable for cutting harder materials like granite. Today, diamond wire saws for granite quarrying offer unparalleled precision and efficiency, making them a preferred choice over traditional methods such as channeling or flame cutting.

Advantages of Using Diamond Wire Saws for Granite Quarrying

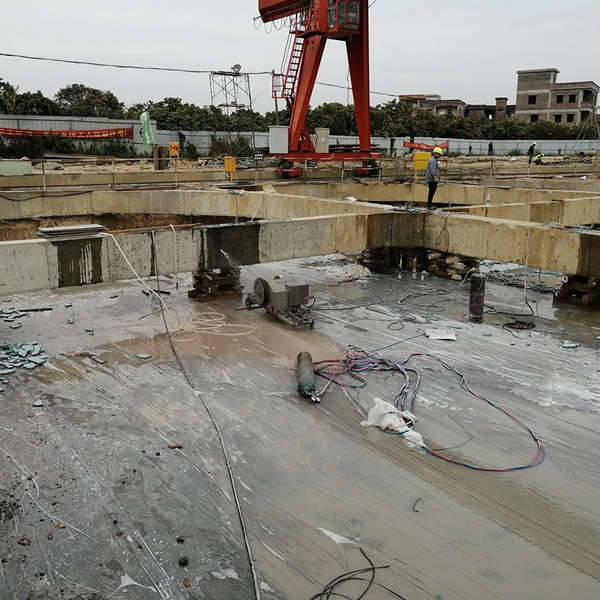

When it comes to extracting granite blocks from quarries, the use of diamond wire saws provides numerous advantages. These include smoother cuts, reduced waste, and the ability to work on complex shapes and sizes. Additionally, the process is quieter and generates less dust compared to other cutting methods, contributing positively to both worker safety and environmental concerns.

Technological Innovations in Diamond Wire Saws for Granite Quarrying

Recent innovations in diamond wire saw technology have further enhanced its capabilities in granite quarrying. Manufacturers are now producing saws with improved diamond concentration and bond hardness, which allows for faster cutting speeds and longer tool life. Electronic controls and GPS tracking systems have also been integrated, enabling operators to monitor and adjust cutting parameters in real-time for optimal performance.

Sustainability and Environmental Impact of Diamond Wire Saws in Granite Quarrying

One of the most compelling reasons for adopting diamond wire saws in granite quarrying is their contribution to sustainable practices. By minimizing material loss during extraction, these saws help conserve natural resources. Moreover, the reduction in noise and dust levels leads to a healthier working environment and lesser impact on surrounding communities. This aligns well with global initiatives aimed at promoting greener manufacturing processes.

Selecting the Right Diamond Wire Saw for Your Granite Quarrying Needs

Choosing the appropriate diamond wire saw for granite quarrying depends on several factors, including the type and hardness of the stone, desired block size, and specific quarry conditions. Consulting with experienced suppliers who can provide tailored solutions based on your operational requirements is crucial. They can guide you through selecting the right wire diameter, diamond concentration, and saw configuration to ensure maximum productivity and cost-effectiveness.

Training and Best Practices for Operating Diamond Wire Saws in Granite Quarrying

To fully leverage the benefits of diamond wire saws, proper training and adherence to best practices are essential. Operators must be well-versed in setup procedures, maintenance routines, and safety protocols. Regular training sessions and updates on the latest technological advancements will keep your team proficient and your operations running smoothly. Implementing these practices not only enhances safety but also maximizes the lifespan and performance of your diamond wire saws.

By embracing the power of diamond wire saws for granite quarrying, businesses can achieve higher yields, better quality products, and a more sustainable approach to stone extraction. As technology continues to evolve, so too will the capabilities of these remarkable tools, promising even greater benefits for the industry in the future.

Request for Quotation

报错: 未找到这个表单