The Releated Products of Diamond Wire Saw For Quarry

Diamond Wire Saw For Quarry

Table of Contents

Diamond Wire Saw for Quarry: Precision Cutting in Stone Extraction

In the world of stone extraction and quarrying, precision and efficiency are paramount. One tool that has revolutionized the industry is the diamond wire saw for quarry. This advanced cutting technology offers unparalleled accuracy and speed, making it indispensable for modern quarries. Let’s delve into the specifics of how this remarkable piece of machinery operates and why it’s become a staple in the industry.

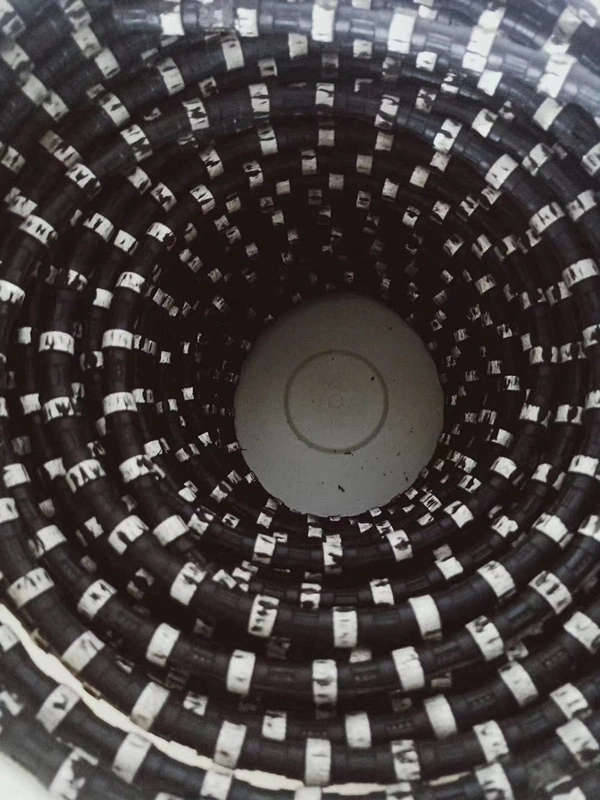

Diamond Wire Saw for Quarry: How It Works

A diamond wire saw for quarry consists of a thin, flexible wire embedded with diamond grains. This wire is continuously fed between two pulleys, which rotate at high speeds. The diamonds on the wire cut through the stone as it moves, creating precise cuts with minimal waste. Unlike traditional methods such as drilling and blasting, the diamond wire saw for quarry provides a cleaner, more controlled cut.

Benefits of Using a Diamond Wire Saw for Quarry

The advantages of using a diamond wire saw for quarry are numerous. Firstly, it allows for silent cutting, reducing noise pollution significantly. Secondly, it can work on any angle, making it highly versatile. Additionally, because the saw uses water to cool the wire and suppress dust, it creates a safer working environment. Lastly, the ability to make straight cuts without causing thermal damage to the stone ensures higher quality end products.

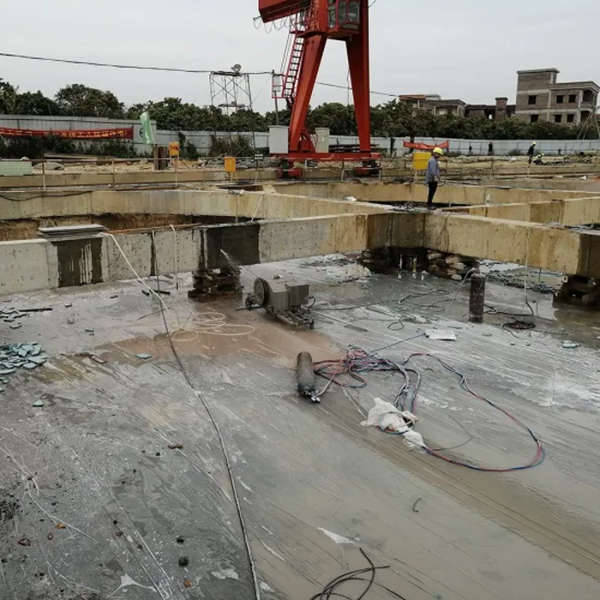

Applications of Diamond Wire Saws in Quarry Operations

From granite to marble, the diamond wire saw for quarry is suitable for extracting a wide range of natural stones. Its application extends beyond basic cutting; it can be used for creating channels, splitting blocks, and even sculpting intricate designs directly from the quarry face. This versatility makes it an essential tool for both large-scale industrial projects and artisanal craftsmanship.

Maintenance and Operation of Diamond Wire Saws for Quarry

To ensure optimal performance and longevity, regular maintenance of your diamond wire saw for quarry is crucial. This includes checking the tension of the wire regularly, ensuring proper alignment of the guide wheels, and replacing worn-out segments promptly. Operators must also receive adequate training to handle the equipment safely and efficiently, maximizing productivity while minimizing risks.

Advancements in Diamond Wire Saw Technology for Quarry

Recent innovations in diamond wire saw for quarry technology have further enhanced its capabilities. Newer models feature improved diamond grit compositions that increase cutting speed and reduce wear. Some advanced systems incorporate GPS tracking and automated controls, allowing for remote operation and precise cutting patterns. These technological upgrades continue to push the boundaries of what’s possible in quarry operations.

Environmental Impact of Diamond Wire Saws in Quarry

While traditionally quarrying has been associated with significant environmental impacts, the use of diamond wire saw for quarry represents a step towards more sustainable practices. By reducing the need for explosives and improving material yield, these saws help minimize the ecological footprint of stone extraction. Moreover, advancements in recycling wastewater used during cutting processes are further contributing to greener quarrying practices.

By adopting diamond wire saw for quarry, operators can achieve greater efficiency, precision, and sustainability in their operations. As technology continues to evolve, we can expect these benefits to become even more pronounced, shaping the future of the stone extraction industry.

Request for Quotation

报错: 未找到这个表单