The Releated Products of Diamond Wire Saw For Stone

Diamond Wire Saw For Stone

Diamond Wire Saw for Stone: Precision Cutting in Modern Masonry

When it comes to precision cutting in the stone industry, few tools match the efficiency and versatility of the diamond wire saw. This innovative technology has revolutionized how quarries operate, enabling faster, more accurate cuts with minimal waste. Let’s delve into the intricacies of diamond wire saws, exploring their applications, benefits, and the science behind their success.

The Basics of Diamond Wire Saws for Stone

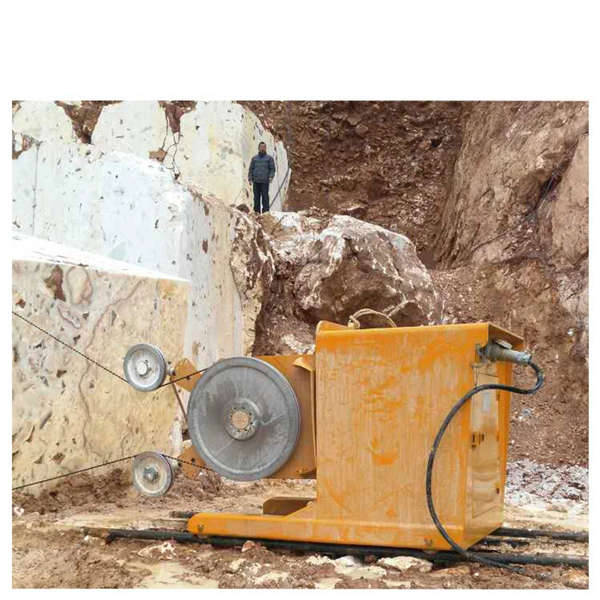

A diamond wire saw for stone is a specialized tool designed for cutting through hard materials like granite, marble, and other types of stone. It consists of a thin metal cable embedded with diamond grains, which act as the cutting edge. The wire moves at high speeds, powered by hydraulic or electric motors, allowing it to slice through dense materials with remarkable ease.

Applications of Diamond Wire Saws for Stone

From architectural projects to large-scale quarry operations, the diamond wire saw for stone finds extensive use across various industries. Its ability to make clean, precise cuts without causing thermal damage to the material makes it particularly useful for cutting intricate shapes and sizes. Whether you’re working on a small countertop or a massive monument, this tool ensures accuracy and efficiency.

How Does a Diamond Wire Saw for Stone Work?

Understanding the mechanics of a diamond wire saw for stone is key to appreciating its effectiveness. The saw operates on a principle similar to sandpaper; the diamond particles embedded in the wire act as abrasive grains that wear away the stone as the wire moves. Water is used during the process to cool the wire and wash away debris, ensuring a smooth operation and reducing the risk of overheating.

Benefits of Using Diamond Wire Saws for Stone

The diamond wire saw for stone offers several advantages over traditional cutting methods:

– Precision: The fine control offered by these saws allows for extremely precise cuts.

– Efficiency: They can cut continuously, leading to higher productivity rates.

– Versatility: Suitable for a wide range of materials and applications.

– Reduced Waste: By minimizing material loss, they contribute to more sustainable practices.

Maintenance and Care of Diamond Wire Saws for Stone

To ensure optimal performance and longevity of your diamond wire saw for stone, regular maintenance is crucial. This includes inspecting the wire for any signs of wear, keeping the equipment clean, and replacing worn parts promptly. Proper storage when not in use also helps protect the integrity of the saw.

Future Innovations in Diamond Wire Saws for Stone

As technology advances, so too does the design and functionality of the diamond wire saw for stone. Manufacturers are continually seeking ways to improve durability, reduce noise levels, and enhance safety features. With ongoing research and development, we can expect even more efficient and eco-friendly models to emerge, further solidifying the diamond wire saw’s position as a cornerstone of modern stonework.

By embracing the capabilities of the diamond wire saw for stone, professionals in the stone industry can achieve unparalleled results, combining artistry with advanced engineering to create stunning, durable structures. Whether you’re a seasoned mason or just starting out, understanding and utilizing this powerful tool can elevate your work to new heights.

Request for Quotation

报错: 未找到这个表单