The Releated Products of Diamond Wire Saw Granite Cutting Machine

Diamond Wire Saw Granite Cutting Machine

Diamond Wire Saw Granite Cutting Machine: Precision and Efficiency in Stone Processing

In the realm of stone processing, precision and efficiency are paramount. One tool that has revolutionized the industry is the Diamond Wire Saw Granite Cutting Machine. This advanced machinery offers unparalleled accuracy and speed when cutting granite, making it indispensable for modern stonework operations.

The Basics of Diamond Wire Saw Granite Cutting Machines

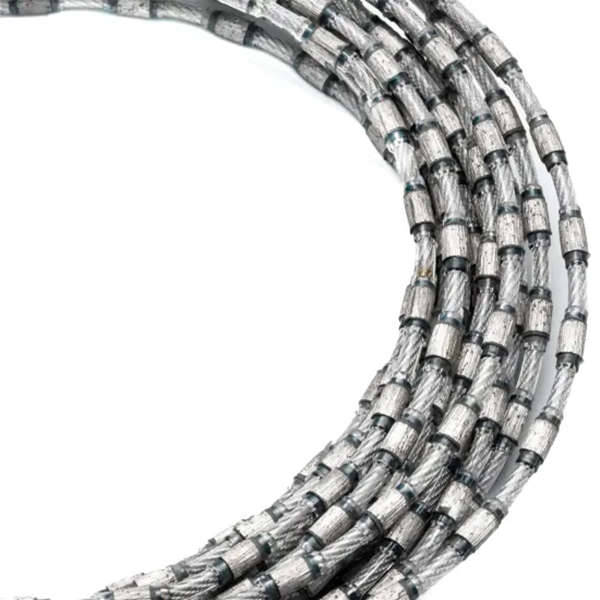

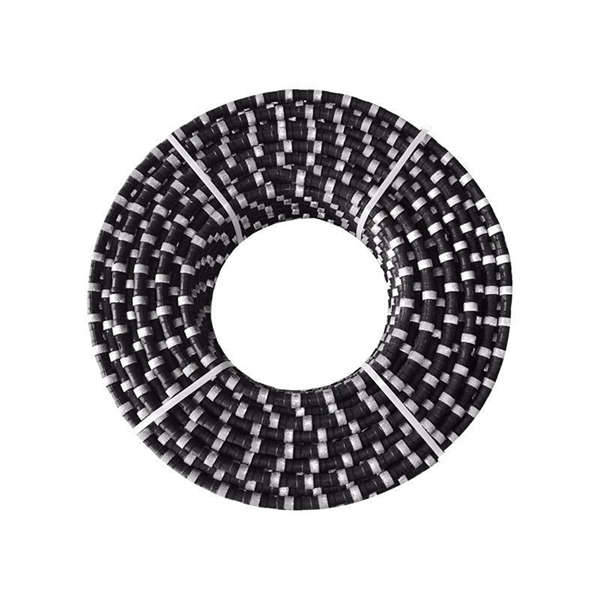

A diamond wire saw consists of a thin metal cable embedded with diamond grains. These machines work by continuously feeding this wire through the material to be cut—most commonly granite. The diamond segments on the wire grind away at the stone, creating clean, precise cuts. Diamond Wire Saw Granite Cutting Machines are versatile tools capable of handling various tasks, from rough shaping to detailed carving.

Advantages of Using Diamond Wire Saws for Granite

The benefits of using a Diamond Wire Saw Granite Cutting Machine are numerous. Firstly, these machines can cut granite slabs of any size or thickness, offering unmatched versatility compared to traditional methods. Additionally, they produce minimal noise and dust, improving workplace safety and reducing environmental impact. The precision of the cuts also reduces material waste, leading to cost savings over time.

How Diamond Wire Saw Granite Cutting Machines Work

Understanding how a Diamond Wire Saw Granite Cutting Machine operates is crucial for maximizing its potential. The process begins by threading the diamond-impregnated wire through guide wheels mounted on a frame. Hydraulic or electric motors then rotate these wheels, pulling the wire through the granite at high speeds. Water is typically used to cool the wire and suppress dust, ensuring smooth operation and prolonging the life of the cutting wire.

Maintenance Tips for Diamond Wire Saw Granite Cutting Machines

To ensure optimal performance and longevity, regular maintenance of your Diamond Wire Saw Granite Cutting Machine is essential. This includes inspecting the wire regularly for signs of wear or damage and replacing it as necessary. Keeping the machine clean, especially the guide wheels and tensioning system, helps prevent premature wear. Lubricating moving parts and checking hydraulic fluid levels are also vital steps in maintaining peak performance.

Applications of Diamond Wire Saw Granite Cutting Machines

From construction sites to sculpture studios, Diamond Wire Saw Granite Cutting Machines find applications across various industries. In construction, they are used for cutting large blocks of granite into smaller pieces suitable for flooring or countertops. Sculptors appreciate the fine control these machines offer, allowing them to create intricate designs with ease. Even in the mining sector, diamond wire saws are employed for selective extraction of high-quality granite without damaging surrounding rock formations.

Choosing the Right Diamond Wire Saw Granite Cutting Machine

When selecting a Diamond Wire Saw Granite Cutting Machine, consider factors such as the size of your projects, the types of materials you work with most often, and your budget. Smaller operations might benefit from portable models designed for occasional use, while larger facilities requiring frequent, heavy-duty cutting will need industrial-grade machines built for continuous operation. Consulting with experienced suppliers can help match you with the ideal machine for your specific needs.

By investing in a Diamond Wire Saw Granite Cutting Machine, businesses can significantly enhance their productivity and product quality, positioning themselves at the forefront of innovation in stone processing.

Request for Quotation

报错: 未找到这个表单