The Releated Products of Diamond Wire Saw Granite Manufacturers

Diamond Wire Saw Granite Manufacturers

Diamond Wire Saw Granite Manufacturers: Precision, Power, and Performance

In the dynamic world of stone processing, diamond wire saw granite manufacturers stand as pioneers of innovation and precision. These manufacturers specialize in creating cutting-edge tools designed to tackle the hardest materials with unparalleled accuracy and efficiency. As the demand for high-quality granite continues to rise, so does the need for advanced diamond wire saws that can meet the rigorous standards set by today’s construction and architectural industries.

The Evolution of Diamond Wire Saws for Granite

The journey of diamond wire saw granite manufacturers begins with understanding the historical context and technological advancements that have shaped this industry. Traditionally, granite was cut using circular blades or gang saws, methods that were both time-consuming and resource-intensive. However, the introduction of diamond wire saw technology marked a significant shift towards faster, cleaner, and more sustainable cutting practices. Diamond-impregnated wires are now capable of slicing through massive blocks of granite with minimal waste and maximum precision.

Key Features of Diamond Wire Saws for Granite

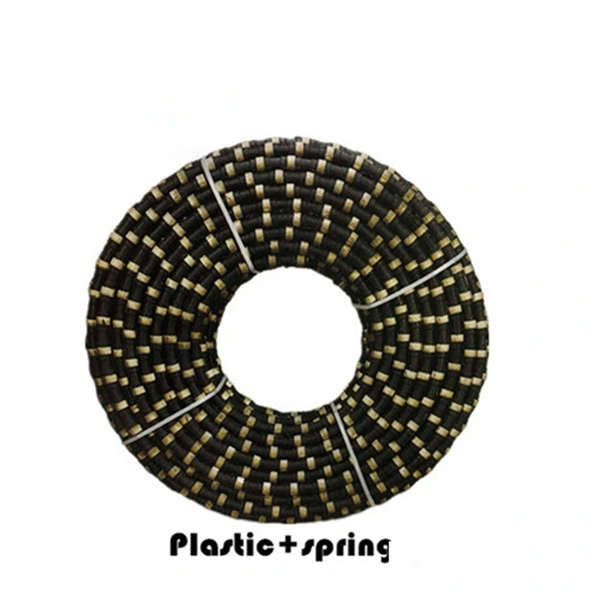

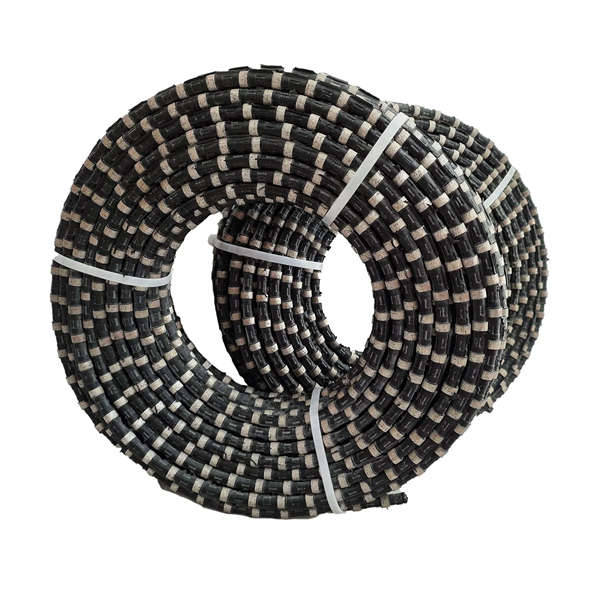

When evaluating diamond wire saw granite manufacturers, it’s essential to consider several key features that define their products’ quality and performance. Firstly, the durability of the wire plays a critical role in its longevity and cost-effectiveness. High-grade steel cores reinforced with industrial diamonds ensure that these wires can withstand the abrasive nature of granite without breaking or losing sharpness. Additionally, the design of the wire’s surface, including the pattern and concentration of diamond segments, greatly influences its cutting speed and finish quality.

Applications of Diamond Wire Saws in Granite Processing

From quarries to fabrication shops, diamond wire saws have become indispensable tools across various stages of granite processing. In quarries, these saws are used to extract large slabs from rock faces with minimal damage to the surrounding environment. At fabrication facilities, they enable precise cuts required for countertops, tiles, and other custom designs. The versatility and adaptability of diamond wire saws make them suitable for both rough and fine cutting operations, ensuring that manufacturers can cater to diverse customer needs efficiently.

Choosing the Right Diamond Wire Saw Granite Manufacturer

Selecting the right diamond wire saw granite manufacturer is crucial for businesses looking to enhance their production capabilities and product quality. A reputable manufacturer will offer a wide range of saws tailored to different applications and material types. They should also provide comprehensive technical support, including training on proper usage and maintenance procedures. Furthermore, investing in a brand known for its research and development efforts ensures access to the latest innovations in cutting technology.

Benefits of Using Diamond Wire Saws for Granite

Beyond just being a tool, diamond wire saws represent a commitment to excellence and sustainability within the granite industry. By reducing waste and improving cut quality, these saws contribute significantly to lowering operational costs while enhancing final product value. Their ability to operate quietly compared to traditional methods makes them ideal for urban environments where noise pollution is a concern. Moreover, the reduced water usage associated with diamond wire cutting techniques aligns well with growing environmental consciousness among consumers and regulatory bodies alike.

Future Trends in Diamond Wire Saw Technology for Granite

As we look toward the future, diamond wire saw granite manufacturers are continuously pushing boundaries to redefine what’s possible with cutting technology. Emerging trends include the integration of automation and robotics into cutting processes, allowing for even greater precision and consistency. Additionally, advancements in diamond synthesis and bonding techniques promise to further enhance the durability and efficiency of these tools. With ongoing investments in R&D, the coming years will likely see diamond wire saws becoming even more indispensable in meeting the evolving demands of the granite industry.

Request for Quotation

报错: 未找到这个表单