The Releated Products of Diamond Wire Saw Machine Factory

Diamond Wire Saw Machine Factory

Table of Contents

Diamond Wire Saw Machine Factory: Precision Cutting Solutions

In the world of industrial cutting, precision and efficiency are paramount. The Diamond Wire Saw Machine Factory stands out as a beacon of innovation, offering unparalleled solutions for materials that were once considered too challenging to cut accurately. This article delves into the intricacies of these machines, their applications, and why they are indispensable in today’s manufacturing landscape.

The Evolution of Diamond Wire Saw Technology in Diamond Wire Saw Machine Factory

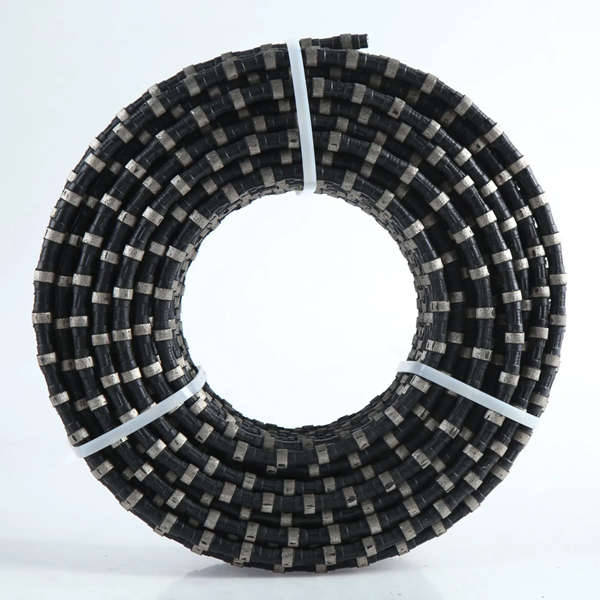

The journey of diamond wire saw technology has been marked by significant advancements aimed at improving cutting performance and reducing operational costs. Diamond Wire Saw Machine Factory has been at the forefront of this evolution, continuously refining its machinery to meet the growing demands of various industries. These machines now boast enhanced durability and cutting speed, thanks to innovations in diamond wire composition and tensioning systems. The result? An ability to slice through dense materials like marble, granite, and reinforced concrete with unprecedented accuracy and minimal material waste.

Applications of Diamond Wire Saws from Diamond Wire Saw Machine Factory

From construction to mining, the applications of diamond wire saws are vast and varied. Diamond Wire Saw Machine Factory caters to a wide range of sectors, providing specialized saws designed for specific tasks. In construction, these saws are essential for controlled demolition and renovation projects where precision is critical. In the mining industry, they excel at extracting valuable minerals without damaging the surrounding rock structure. Additionally, the automotive sector benefits from their use in recycling processes, efficiently separating parts for reuse or disposal.

Advantages of Using Diamond Wire Saws from Diamond Wire Saw Machine Factory

One of the key advantages of using diamond wire saws produced by the Diamond Wire Saw Machine Factory is their versatility. These saws can handle both soft and hard materials with equal ease, making them a versatile tool in any workshop or on-site operation. They also offer a cleaner cut compared to traditional methods, reducing the need for post-cut finishing work. Moreover, the low vibration levels during operation contribute to a safer working environment, enhancing operator comfort and reducing the risk of injury.

Innovative Features of Diamond Wire Saws from Diamond Wire Saw Machine Factory

To stay ahead in a competitive market, Diamond Wire Saw Machine Factory invests heavily in research and development. This commitment has led to the introduction of several innovative features that set their products apart. For instance, advanced electronic controls allow for precise adjustment of cutting parameters, ensuring optimal performance across different materials. Enhanced cooling systems prevent overheating, extending the life of the diamond wire and maintaining consistent cutting quality over extended periods.

Sustainability Initiatives by Diamond Wire Saw Machine Factory

Recognizing the environmental impact of industrial operations, Diamond Wire Saw Machine Factory has taken proactive steps towards sustainability. Their focus on energy efficiency reduces the carbon footprint associated with cutting operations. Furthermore, efforts are underway to recycle used diamond wires, minimizing waste and lowering the total cost of ownership for customers. These initiatives not only benefit the planet but also align with the growing demand from consumers and regulatory bodies for greener manufacturing practices.

The Future of Diamond Wire Saw Machines from Diamond Wire Saw Machine Factory

Looking ahead, the Diamond Wire Saw Machine Factory is poised to continue pushing boundaries in cutting technology. With ongoing investments in automation and artificial intelligence, the factory aims to develop even more sophisticated systems capable of adapting to complex cutting scenarios autonomously. This will not only enhance productivity but also open up new possibilities for industries seeking to leverage advanced materials and manufacturing techniques. As we move forward, it’s clear that diamond wire saws will remain a critical component in shaping our built environment and advancing industrial capabilities globally.

Request for Quotation

报错: 未找到这个表单