The Releated Products of Diamond Wire Saw Nz

Diamond Wire Saw Nz

Diamond Wire Saw NZ: Precision Cutting for Tough Materials

In the realm of construction and industrial cutting, precision and efficiency are paramount. Diamond Wire Saw NZ stands out as a revolutionary technology designed to meet these demands. This method offers unparalleled accuracy and speed, making it a preferred choice among professionals dealing with tough materials such as reinforced concrete, brick, and stone. Let’s delve into the details of what makes diamond wire sawing in New Zealand so effective.

Diamond Wire Saw NZ: An Overview

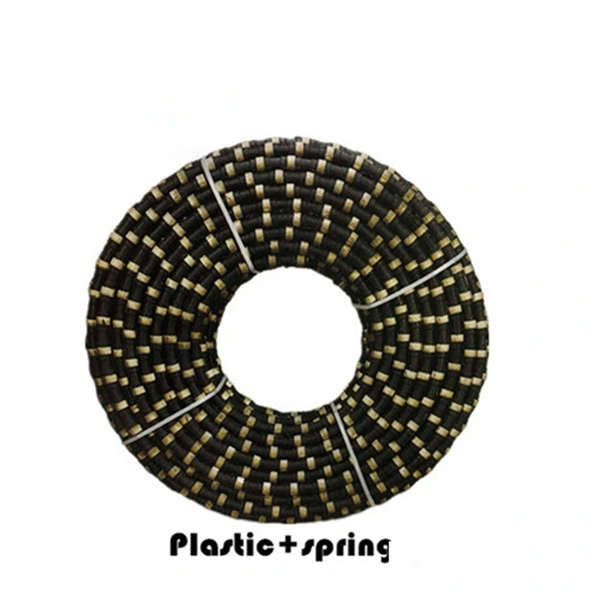

Diamond Wire Saw NZ refers to the process of using a thin, flexible wire embedded with diamond particles to cut through various hard substances. The wire is typically made of steel and coated with diamond segments that act as cutting tools. When operated at high speeds, this wire can slice through materials with minimal vibration and dust, ensuring clean cuts every time.

The use of diamond wire saws has become increasingly popular in New Zealand due to their ability to handle large-scale projects efficiently. Whether it’s bridge construction or demolition work, these saws provide a level of control and precision unmatched by traditional methods.

Benefits of Diamond Wire Saw NZ

One of the key advantages of Diamond Wire Saw NZ technology is its versatility. It can be used in confined spaces where other cutting methods would be impractical. Additionally, because the wire can be guided around obstacles, it allows for more intricate cuts without compromising safety or accuracy.

Another significant benefit is the reduction in noise and vibration during operation. This not only creates a safer working environment but also minimizes disruption to nearby areas. Moreover, the water-cooled system used in diamond wire sawing helps keep dust levels down, contributing to better air quality on site.

Applications of Diamond Wire Saw NZ

The applications of Diamond Wire Saw NZ span across multiple industries including construction, mining, and civil engineering. In construction, it is often employed for cutting deep slabs, removing bridge decks, and creating openings in walls and floors.

In the mining sector, diamond wire saws are utilized for extracting gemstones and minerals from quarries. This application showcases the saw’s capability to work with both soft and hard rock formations, making it an indispensable tool in resource extraction operations.

How Diamond Wire Saw NZ Works

Understanding how Diamond Wire Saw NZ operates provides insight into why it is so effective. The process begins with setting up the sawing unit, which consists of two drive units connected by the diamond-impregnated wire. Once set up, the wire is tensioned and then rotated at high speeds to cut through the material.

Water is continuously fed onto the cutting area to cool the wire and suppress dust. This ensures that the cutting process remains efficient while maintaining optimal working conditions. The continuous nature of the cut means that even very thick sections can be processed effectively, allowing for rapid progress on large projects.

Maintenance and Care of Diamond Wire Saw NZ

To ensure longevity and optimal performance of your Diamond Wire Saw NZ equipment, regular maintenance is essential. This includes inspecting the wire for wear and tear, checking the alignment of guide wheels, and replacing worn parts promptly.

Proper storage when not in use is also crucial. Keeping the saw dry and free from debris will prevent corrosion and extend its lifespan. Additionally, using manufacturer-recommended lubricants on moving parts can significantly reduce wear, ensuring that your diamond wire saw continues to deliver precise results over time.

Future Prospects for Diamond Wire Saw NZ

As technology advances, we can expect to see further improvements in Diamond Wire Saw NZ capabilities. Innovations in diamond segment design may lead to even faster cutting rates and longer-lasting wires. Integration with automation systems could also enhance productivity by allowing remote operation and monitoring of cutting processes.

Moreover, advancements in environmental sustainability might result in more eco-friendly cooling systems that further reduce the carbon footprint associated with construction activities. As industries continue to evolve, Diamond Wire Saw NZ will undoubtedly remain at the forefront, driving progress and efficiency in material cutting applications.

Request for Quotation

报错: 未找到这个表单