The Releated Products of Diamond Wire Saw Rope Factory

Diamond Wire Saw Rope Factory

Table of Contents

Diamond Wire Saw Rope: Precision Engineering for Industrial Applications

In the heart of modern industrial operations lies a technology that epitomizes precision and efficiency—diamond wire saw rope. This specialized tool has revolutionized the way hard materials are cut, from construction sites to quarries. A diamond wire saw rope factory is where these marvels of engineering are born, combining advanced metallurgy with cutting-edge manufacturing techniques to produce tools that can tackle the toughest jobs. Understanding the intricacies involved in their production offers insights into why they stand out in today’s competitive market.

Diamond Wire Saw Rope Design and Manufacturing

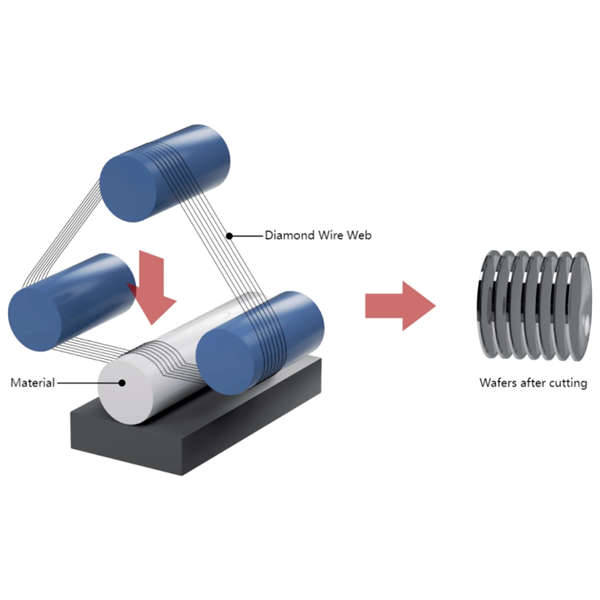

The design phase of diamond wire saw rope is crucial, as it sets the foundation for its performance capabilities. Engineers at the factory meticulously plan each component, ensuring that the wire’s strength, flexibility, and abrasive properties meet or exceed industry standards. High-quality steel cores form the backbone of the rope, providing necessary tensile strength while maintaining sufficient flexibility for maneuverability around complex shapes and contours.

Diamond segments are then electroplated or sintered onto the wire, creating a durable cutting edge capable of slicing through granite, marble, and reinforced concrete with ease. This process requires precise temperature control and chemical composition adjustments to achieve optimal bonding between the wire core and diamond particles.

Quality Control in Diamond Wire Saw Rope Production

Ensuring consistent quality throughout the manufacturing process is paramount for any reputable diamond wire saw rope factory. Stringent testing procedures are implemented at every stage, from raw material inspection to final product evaluation. Non-destructive testing methods such as X-ray fluorescence and ultrasonic examinations help identify potential flaws within the wire structure early on, preventing faulty products from reaching customers.

Moreover, performance metrics like cutting speed, durability under extreme conditions, and resistance to wear and tear are rigorously tested against established benchmarks. Only those wires passing all quality checks with flying colors proceed to packaging and distribution, guaranteeing users receive a tool that delivers reliable results time after time.

Sustainability Practices in Diamond Wire Saw Rope Factories

Environmental consciousness has become increasingly important across industries, including those involved in diamond wire saw rope manufacturing. Leading factories have embraced sustainable practices aimed at reducing waste, conserving resources, and minimizing their carbon footprint. Recycling programs for used wires not only reduce disposal issues but also recover valuable materials for reuse.

Energy-efficient machinery and processes reduce overall power consumption during production, contributing to lower greenhouse gas emissions. Additionally, innovations in design and materials science lead to longer-lasting products that require less frequent replacement, further decreasing environmental impact over the product lifecycle.

Innovations Driving Diamond Wire Saw Rope Technology Forward

Continuous innovation drives the evolution of diamond wire saw rope technology, pushing boundaries of what’s possible in material cutting applications. Research and development teams within leading factories explore new alloys, diamond configurations, and bonding techniques to enhance cutting efficiency and longevity.

Emerging trends include the integration of smart sensors into the wire itself, allowing real-time monitoring of operational parameters such as temperature, vibration levels, and wear progression. Such data-driven insights enable predictive maintenance schedules, optimizing equipment utilization and extending service life.

Customization Options for Diamond Wire Saw Ropes

Recognizing that no two cutting jobs are alike, many diamond wire saw rope factories offer customization services tailored to specific client needs. Factors like wire diameter, diamond grit size, segment spacing, and total length can be adjusted according to project requirements, ensuring the most suitable tool is available for each task.

This level of personalization reflects a commitment to meeting diverse customer demands while maintaining high standards of quality and performance. Whether tackling large-scale construction projects or intricate stonework, having access to precisely configured diamond wire saw ropes empowers professionals to achieve their objectives efficiently and effectively.

Through a combination of rigorous design principles, stringent quality assurance measures, eco-friendly practices, and ongoing technological advancements, diamond wire saw rope factories continue to set new benchmarks in their field. Their dedication to excellence ensures that these indispensable tools remain at the forefront of industrial cutting solutions, supporting countless projects worldwide with unparalleled precision and reliability.

Request for Quotation

报错: 未找到这个表单