The Releated Products of Granit Diamond Wire Saw

Granit Diamond Wire Saw

Table of Contents

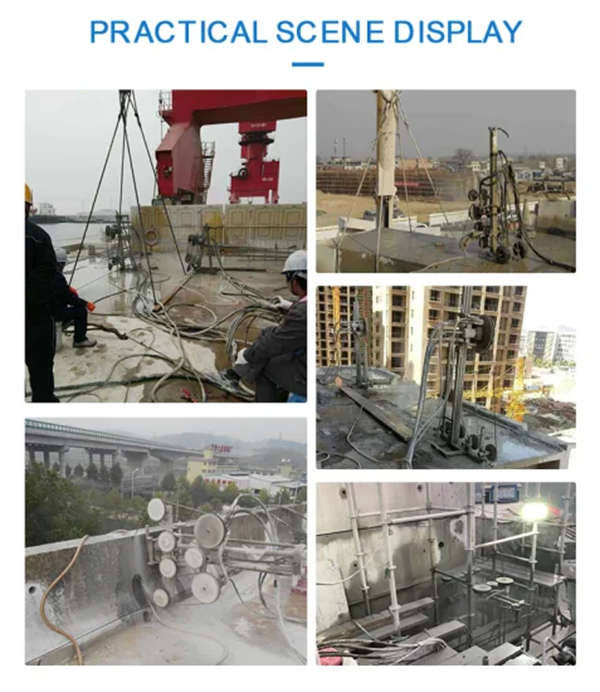

Granit Diamond Wire Saw: Precision in Stone Cutting

In the realm of stone cutting and mining, precision and efficiency are paramount. The introduction of the Granit Diamond Wire Saw has revolutionized how quarries and construction sites operate, offering unparalleled accuracy and speed. This advanced technology stands out for its ability to cut through the hardest materials with minimal effort, making it a preferred choice among professionals worldwide.

Granit Diamond Wire Saw: A Game-Changer in Quarrying

The Granit Diamond Wire Saw is designed specifically for quarrying operations where precision and speed are critical. Equipped with diamond-impregnated wire, this saw can slice through granite, marble, and other hard stones with ease. Its design allows for cleaner cuts, reducing waste and increasing productivity on site. The flexibility of the wire enables it to navigate around obstacles, providing a versatile solution for various quarrying needs.

Enhancing Efficiency with the Granit Diamond Wire Saw

When it comes to improving operational efficiency, the Granit Diamond Wire Saw delivers exceptional results. By using a continuous loop of wire embedded with industrial diamonds, it achieves smooth, controlled cuts every time. This method significantly reduces the time required for cutting compared to traditional methods, thereby boosting overall productivity. Moreover, the reduced noise and dust production make it an environmentally friendly option, enhancing workplace conditions.

Precision Cutting Made Possible by Granit Diamond Wire Saw

One of the key advantages of the Granit Diamond Wire Saw lies in its precision. Whether you’re working on intricate designs or large-scale projects, this saw ensures that each cut meets the highest standards of accuracy. The wire’s thinness allows for tighter radii and more detailed work, which is particularly beneficial for artists and craftsmen looking to create bespoke pieces from natural stone.

Cost-Effectiveness of Using Granit Diamond Wire Saw

Investing in the Granit Diamond Wire Saw not only enhances quality but also offers long-term cost savings. Due to its efficient cutting process, there is less material wastage, leading to substantial savings over time. Additionally, the durability of diamond wire means fewer replacements and lower maintenance costs compared to conventional saws. For businesses aiming to streamline their operations while maintaining high standards, this investment proves highly rewarding.

Environmental Impact of Granit Diamond Wire Saw Usage

Sustainability is becoming increasingly important across all industries, including construction and mining. The Granit Diamond Wire Saw contributes positively to environmental efforts by minimizing water usage and producing less dust and noise pollution. This eco-friendly approach aligns well with companies’ goals of reducing their carbon footprint without compromising on performance or output.

Future Innovations in Granit Diamond Wire Saw Technology

As technology advances, so does the potential of the Granit Diamond Wire Saw. Manufacturers are continuously exploring ways to enhance the capabilities of these saws, focusing on areas such as automation, wireless control systems, and even smarter materials for the wire itself. These developments promise even greater precision, speed, and efficiency in future models, setting new benchmarks for the industry.

By embracing the Granit Diamond Wire Saw, businesses can achieve higher levels of productivity, precision, and sustainability. Its innovative design and robust performance make it an indispensable tool for modern stone cutting and quarrying operations, paving the way for a brighter, more efficient future in the industry.

Request for Quotation

报错: 未找到这个表单