The Releated Products of Granite Cutting Machine Manufacturers

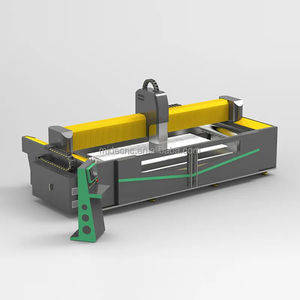

Granite Cutting Machine Manufacturers

Table of Contents

Granite Cutting Machine Manufacturers: Pioneering Precision

In the world of construction and architecture, precision is paramount. This is especially true when it comes to working with granite—a material known for its durability and beauty. Granite cutting machine manufacturers play a critical role in ensuring that this natural stone is processed accurately and efficiently. These machines are designed to meet the rigorous demands of the industry, offering solutions that range from basic cutting tasks to sophisticated shaping and polishing.

Innovative Technologies by Granite Cutting Machine Manufacturers

The advancements in technology have significantly impacted the capabilities of granite cutting machine manufacturers. Today, these machines incorporate state-of-the-art features such as CNC (Computer Numerical Control) systems, which allow for precise cuts and complex designs. Laser-guided mechanisms further enhance accuracy, enabling operators to achieve flawless edges and intricate patterns. By embracing innovation, manufacturers are not only improving the quality of their products but also making the process more sustainable and cost-effective.

Global Reach of Granite Cutting Machine Manufacturers

As the demand for granite products continues to grow globally, so does the need for reliable granite cutting machinery. Leading manufacturers are expanding their presence internationally, establishing partnerships and distribution networks that span continents. This global reach ensures that regardless of location, businesses can access high-quality equipment tailored to their specific needs. It also facilitates the exchange of ideas and best practices, driving continuous improvement across the industry.

Sustainability Efforts by Granite Cutting Machine Manufacturers

Environmental consciousness has become a key consideration for many industries, including those involved in granite processing. Recognizing this shift, granite cutting machine manufacturers are increasingly focusing on developing eco-friendly solutions. From reducing water consumption during cutting processes to minimizing waste and recycling materials, these efforts demonstrate a commitment to sustainability without compromising on performance or efficiency. As a result, companies can now choose from a range of environmentally responsible options that align with their corporate social responsibility goals.

Customization Options Offered by Granite Cutting Machine Manufacturers

No two projects are alike, which is why customization plays a crucial role in the success of granite cutting operations. Leading manufacturers understand this and offer a variety of customization options to meet diverse customer requirements. Whether it’s adapting machines for specific stone types, integrating additional functionalities, or designing bespoke solutions, the flexibility provided by these companies ensures that users can tailor their equipment precisely to their needs. This level of personalization supports both small-scale artisans and large industrial facilities in achieving optimal results.

Training and Support Services from Granite Cutting Machine Manufacturers

Investing in advanced machinery is only one part of the equation; proper training and ongoing support are equally important. Top-tier granite cutting machine manufacturers provide comprehensive training programs designed to help operators get the most out of their equipment. These may include hands-on workshops, online tutorials, and dedicated technical assistance teams. Additionally, robust after-sales services ensure that any issues are addressed promptly, keeping downtime to a minimum and maximizing productivity.

By focusing on these areas, granite cutting machine manufacturers continue to push the boundaries of what’s possible within the industry. Their contributions not only streamline workflows but also elevate the standard of craftsmanship associated with granite products worldwide.

Request for Quotation

报错: 未找到这个表单