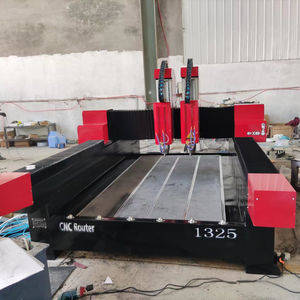

The Releated Products of Granite Marble Cutter

Granite Marble Cutter

Granite Marble Cutter: Precision in Stone Crafting

In the world of construction and interior design, natural stones like granite and marble have become synonymous with elegance and durability. To harness the full potential of these materials, professionals rely on specialized tools, one of which is the granite marble cutter. This tool is not just any piece of equipment; it’s a precision instrument designed to meet the demanding standards of artisans and contractors alike. Let’s delve into the world of granite marble cutters, exploring their features, applications, and the technology behind them.

Choosing the Right Granite Marble Cutter

Selecting the right granite marble cutter is crucial for achieving clean cuts and maintaining the integrity of the stone. Factors such as blade size, motor power, and water cooling systems play significant roles in determining the efficiency and effectiveness of the cutting process. For instance, a larger blade can handle thicker slabs of stone, while a powerful motor ensures smooth operation even when cutting through the hardest materials.

Advanced Features of Modern Granite Marble Cutters

Modern granite marble cutters come equipped with advanced features that enhance performance and safety. Anti-vibration handles reduce operator fatigue during prolonged use, while dust collection systems minimize airborne particles, creating a cleaner working environment. Additionally, many models now incorporate laser guides for precise alignment, ensuring straight cuts every time.

Applications of Granite Marble Cutters

The versatility of granite marble cutters extends beyond simple countertop installations. They are indispensable in various applications, from creating intricate designs for flooring and wall cladding to producing custom pieces for furniture and decorative elements. Whether you’re a professional contractor or a DIY enthusiast, having access to a high-quality granite marble cutter opens up a world of creative possibilities.

Maintenance Tips for Your Granite Marble Cutter

To ensure your granite marble cutter performs optimally over its lifetime, regular maintenance is essential. This includes keeping the blade sharp, cleaning the machine thoroughly after each use, and inspecting all parts for wear and tear. Proper care not only prolongs the life of your tool but also maintains its cutting precision, which is vital when working with expensive materials like granite and marble.

Safety Considerations When Using a Granite Marble Cutter

Safety must always be a priority when operating any power tool, especially one as potent as a granite marble cutter. Always wear appropriate personal protective equipment (PPE), including safety glasses, gloves, and hearing protection. Familiarize yourself with the manufacturer’s instructions and recommended safety practices. Remember, taking precautions can prevent accidents and injuries, ensuring a safer work environment for everyone involved.

The Future of Granite Marble Cutting Technology

As technology continues to evolve, so do the tools used in the industry. Future granite marble cutters are likely to feature more sophisticated automation, improved ergonomics, and enhanced safety mechanisms. Innovations such as smart sensors and IoT connectivity could revolutionize how we interact with these machines, making them even more efficient and user-friendly.

By understanding the capabilities and proper usage of granite marble cutters, professionals can elevate their craft, delivering projects that not only meet but exceed client expectations. Whether you’re new to the field or a seasoned expert, investing in a quality granite marble cutter is an investment in your future success.

Request for Quotation

报错: 未找到这个表单