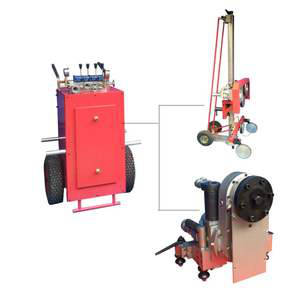

The Releated Products of Granite Marble Cutting Machine

Granite Marble Cutting Machine

Table of Contents

Granite Marble Cutting Machine: Precision in Stone Crafting

In the world of stone crafting, precision and efficiency are paramount. The granite marble cutting machine stands out as a revolutionary tool that has transformed the industry. By combining advanced technology with robust design, these machines ensure that artisans can achieve flawless cuts on even the hardest stones.

Advantages of Using a Granite Marble Cutting Machine

One of the most significant benefits of using a granite marble cutting machine is its ability to deliver clean, precise cuts. This capability is crucial when working with materials like granite and marble, which require accuracy down to the millimeter. Additionally, these machines offer unparalleled speed compared to traditional methods, significantly reducing production time without compromising on quality.

Technological Innovations in Granite Marble Cutting Machines

Modern granite marble cutting machines incorporate state-of-the-art technologies designed to enhance performance and user safety. Features such as automatic water cooling systems prevent overheating during operation, extending the life of the blade and ensuring consistent cutting quality. Moreover, digital interfaces allow operators to input specific measurements, enabling the machine to make complex cuts with ease and repeatability.

Maintenance Requirements for Granite Marble Cutting Machines

To keep your granite marble cutting machine operating at peak efficiency, regular maintenance is essential. This includes cleaning the machine thoroughly after each use to remove any debris or dust that might accumulate. Regularly inspecting and replacing worn parts, like blades and seals, also helps maintain optimal performance levels. Following the manufacturer’s guidelines for lubrication and storage ensures that your investment lasts longer and performs better over time.

Safety Measures When Operating a Granite Marble Cutting Machine

Safety should always be a top priority when working with heavy machinery like a granite marble cutting machine. Operators must wear appropriate personal protective equipment (PPE), including eye protection, gloves, and hearing protection. It’s also important to ensure that all safety guards are in place and functioning correctly before starting the machine. Familiarizing yourself with emergency stop procedures and conducting regular safety drills can help prevent accidents in the workplace.

Selecting the Right Granite Marble Cutting Machine

Choosing the right granite marble cutting machine depends on several factors, including the size of your projects, the types of materials you work with, and your budget. For small-scale operations, a compact model might suffice; however, larger businesses may require more powerful industrial-grade machines capable of handling continuous use. Consider consulting with industry experts or reading reviews from other professionals to find a machine that meets your specific needs and expectations.

Future Trends in Granite Marble Cutting Technology

As technology continues to advance, we can expect to see further improvements in granite marble cutting machines. Developments in artificial intelligence and robotics could lead to fully automated systems capable of performing complex tasks with minimal human intervention. Furthermore, innovations in blade design and material science promise to increase durability while reducing energy consumption, making these machines not only more efficient but also environmentally friendly.

Request for Quotation

报错: 未找到这个表单