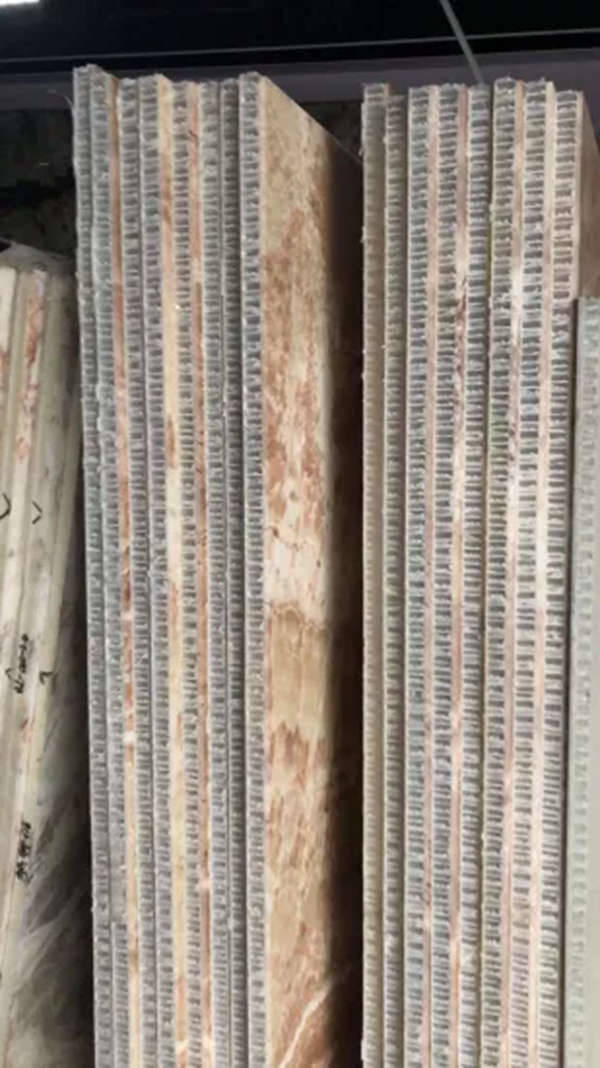

The Releated Products of Hand Diamond Wire Saw

Hand Diamond Wire Saw

Hand Diamond Wire Saw: Precision Cutting for Tough Materials

When it comes to precision cutting in tight spaces or on complex projects, the hand diamond wire saw stands out as a versatile and indispensable tool. This advanced piece of equipment is designed to handle materials that traditional saws cannot, making it a go-to choice for professionals in construction, mining, and stonework. In this article, we explore the features, benefits, and applications of the hand diamond wire saw, highlighting its role in enhancing efficiency and accuracy across various industries.

Advantages of Using a Hand Diamond Wire Saw

One of the primary reasons why the hand diamond wire saw has gained popularity is due to its unparalleled precision and maneuverability. Unlike conventional saws, which may struggle with curved cuts or detailed work, the diamond wire saw allows for intricate designs and shapes to be cut with ease. Its lightweight design and ergonomic handle make it ideal for extended use without causing strain on the user.

Applications of the Hand Diamond Wire Saw

The hand diamond wire saw finds extensive use in a variety of applications where precision and flexibility are paramount. From cutting through reinforced concrete in demolition projects to shaping marble and granite for architectural purposes, this tool excels. It can also be used effectively in the extraction of valuable stones from quarries, ensuring minimal damage to the surrounding material.

How Does a Hand Diamond Wire Saw Work?

Understanding how a hand diamond wire saw operates provides insight into its capabilities and limitations. Essentially, it consists of a thin wire embedded with diamond grains that rotate at high speeds, slicing through materials like butter. The wire is guided by pulleys attached to a frame, which can be adjusted according to the needs of the job. A steady stream of water cools the wire during operation, reducing friction and preventing overheating.

Choosing the Right Hand Diamond Wire Saw

Selecting the appropriate hand diamond wire saw depends largely on the specific requirements of your project. Factors such as the type and hardness of the material being cut, the size of the cut required, and the environment in which the work will take place all play crucial roles in determining the best model. Considerations might include blade length, motor power, and additional features like dust collection systems or adjustable speed controls.

Maintenance and Safety Tips for Hand Diamond Wire Saws

To ensure longevity and optimal performance, proper maintenance of your hand diamond wire saw is essential. Regular cleaning and inspection of the wire, pulleys, and motor components help prevent premature wear and tear. Always follow manufacturer guidelines regarding lubrication and replacement parts. Additionally, prioritize safety by wearing protective gear, keeping the workspace organized, and familiarizing yourself with emergency procedures.

Future Innovations in Hand Diamond Wire Saw Technology

As technology continues to advance, so too does the design and functionality of the hand diamond wire saw. Innovations such as wireless operation, improved battery life, and enhanced durability are making these tools even more accessible and efficient. Developers are also focusing on creating more eco-friendly models that reduce noise pollution and waste production during use.

In conclusion, the hand diamond wire saw represents a significant leap forward in cutting technology, offering unparalleled precision and versatility. Whether you’re a seasoned professional or just starting out, investing in a quality hand diamond wire saw can greatly enhance your ability to tackle challenging projects with confidence and precision.

Request for Quotation

报错: 未找到这个表单