The Releated Products of Hand Wire Saw Diamond Tools

Hand Wire Saw Diamond Tools

Table of Contents

Hand Wire Saw Diamond Tools: Precision Cutting for Tough Materials

When it comes to cutting through dense or hard materials, hand wire saw diamond tools stand out as a versatile solution. These specialized tools combine the strength of diamonds with the maneuverability of a hand-held design, making them indispensable in various industries. Whether you’re working on construction projects, mining operations, or even intricate stonework, understanding the benefits and applications of hand wire saw diamond tools can significantly enhance your work efficiency and precision.

Advantages of Hand Wire Saw Diamond Tools

Hand wire saw diamond tools offer several advantages over traditional cutting methods. Their primary benefit lies in their ability to cut through extremely hard materials such as concrete, stone, and reinforced metals with minimal effort. This makes them ideal for applications where precision and clean cuts are paramount. Additionally, these tools produce less noise and vibration compared to other cutting tools, reducing fatigue and enhancing user comfort during extended use.

Applications of Hand Wire Saw Diamond Tools

The versatility of hand wire saw diamond tools means they find application across multiple sectors. In construction, they are used for demolition and renovation projects, allowing for controlled removal of concrete structures without damaging surrounding areas. For stonemasons and sculptors, these tools provide a means to carve and shape natural stones with greater ease and accuracy. Even in the mining industry, hand wire saw diamond tools facilitate the extraction of valuable minerals from quarries by enabling precise cuts that maximize yield.

Maintenance of Hand Wire Saw Diamond Tools

To ensure optimal performance and longevity, proper maintenance of hand wire saw diamond tools is essential. Regular cleaning to remove debris and residue helps maintain the tool’s cutting efficiency. Lubricating moving parts periodically prevents wear and tear, while storing the tools in a dry place when not in use protects against corrosion. It’s also important to inspect the wire regularly for signs of damage or fraying, replacing it promptly to avoid accidents or decreased cutting effectiveness.

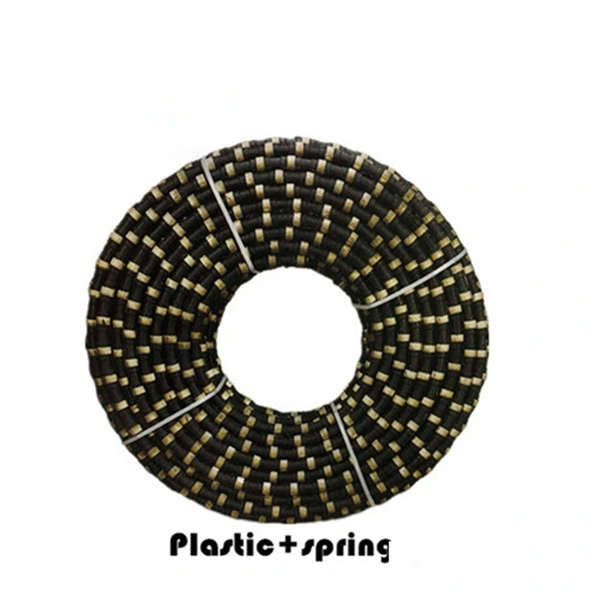

Types of Hand Wire Saw Diamond Tools

There are different types of hand wire saw diamond tools available, each suited to specific tasks. Some models feature adjustable tension settings, allowing users to customize the tightness of the wire based on the material being cut. Others come equipped with ergonomic handles designed to reduce strain during prolonged use. Choosing the right type depends largely on the nature of the job at hand, from fine-detail work requiring maximum control to larger-scale operations demanding robust durability.

Choosing the Right Hand Wire Saw Diamond Tool

Selecting the appropriate hand wire saw diamond tool involves considering factors such as the hardness of the material being cut, the desired depth of cut, and the level of precision required. Professionals often opt for tools with replaceable diamond wires, ensuring cost-effectiveness over time as only the worn-out part needs replacement rather than the entire unit. For beginners or those tackling occasional projects, more basic models may suffice, offering good value for money without compromising on essential features.

Innovations in Hand Wire Saw Diamond Tools

As technology advances, so too does the design and functionality of hand wire saw diamond tools. Recent innovations include the development of diamond wires with enhanced abrasion resistance, capable of lasting longer under harsh conditions. Smart sensors that monitor temperature and pressure during operation are being integrated into some models, alerting users to potential issues before they become serious problems. Such advancements continue to push the boundaries of what these tools can achieve, making them even more indispensable for professionals across diverse fields.

Request for Quotation

报错: 未找到这个表单