The Releated Products of How A Diamond Wire Saw Works

How A Diamond Wire Saw Works

How A Diamond Wire Saw Works: Precision Cutting for Tough Materials

In the realm of industrial cutting, precision and efficiency are paramount. One tool that has revolutionized the way we cut through tough materials is the diamond wire saw. This advanced technology provides unparalleled accuracy and versatility, making it indispensable in various industries, from construction to mining. To understand its significance, let’s delve into how a diamond wire saw works.

Diamond Wire Saw Components: The Building Blocks of Precision

The fundamental components of a diamond wire saw include a motor, a series of pulleys, and the diamond-impregnated wire itself. The wire, embedded with industrial-grade diamonds, acts as the cutting blade. These components work together seamlessly to ensure clean, precise cuts even through the hardest substances like reinforced concrete or granite.

Power Source and Motor: Driving the Diamond Wire

A powerful motor drives the system, transferring energy to the pulleys which then rotate, pulling the wire through the material being cut. The strength and reliability of the motor directly impact the speed and effectiveness of the cutting process. Modern diamond wire saws often come equipped with adjustable speed settings, allowing operators to optimize performance based on the specific material and task at hand.

Pulley System: Ensuring Smooth Operation

The pulley system is crucial for maintaining tension in the diamond wire and guiding it through the material accurately. Typically, there are several pulleys involved, including drive pulleys and idler pulleys. Drive pulleys are connected directly to the motor, while idler pulleys help maintain tension and guide the wire around obstacles. Proper alignment of these pulleys is essential for efficient operation and longevity of the saw.

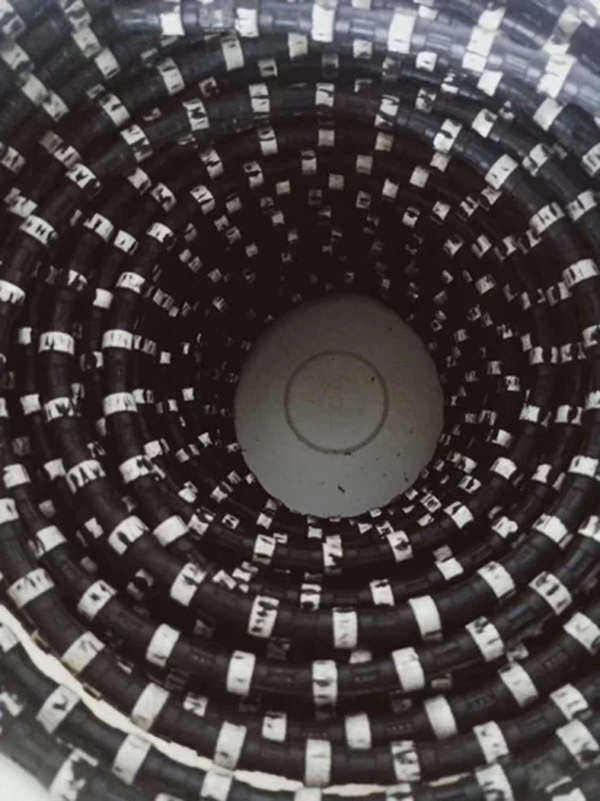

Diamond-Embedded Wire: The Cutting Edge

Perhaps the most critical component is the diamond-embedded wire, which does the actual cutting. Diamonds, known for their hardness, are embedded along the length of a steel cable. When this wire is pulled taut and moved at high speeds by the pulley system, it can slice through virtually any material. The durability and sharpness of the diamonds make them ideal for this application, ensuring that the saw can tackle even the toughest jobs without losing its edge.

Lubrication and Cooling Systems: Maintaining Performance

To keep the diamond wire saw operating at peak efficiency, proper lubrication and cooling are necessary. Water is commonly used not only to cool the wire during cutting but also to wash away debris, preventing overheating and wear on the diamonds. Some advanced models may feature built-in water pumps or external water supply systems to ensure consistent flow over the cutting area.

Applications of Diamond Wire Saws: Versatility in Action

From slicing through massive blocks of marble in quarries to removing sections of concrete in urban construction sites, diamond wire saws have found numerous applications across different sectors. Their ability to make precise cuts with minimal vibration and dust makes them particularly valuable in environments where traditional cutting methods might be too disruptive or imprecise.

Understanding how a diamond wire saw works reveals the sophisticated engineering behind this versatile tool. Its components work harmoniously to deliver unmatched precision and efficiency, making it an indispensable asset in many industries. Whether you’re involved in construction, mining, or manufacturing, investing in a quality diamond wire saw can significantly enhance your operations’ productivity and outcomes.

Request for Quotation

报错: 未找到这个表单