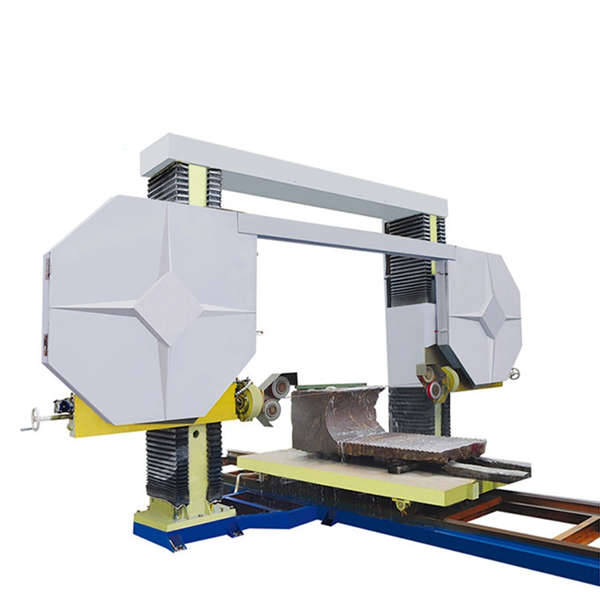

The Releated Products of Mini Diamond Wire Saw

Mini Diamond Wire Saw

Mini Diamond Wire Saw: Precision Cutting in Compact Form

In the realm of precision cutting, mini diamond wire saws have emerged as indispensable tools for professionals seeking accuracy and efficiency. These compact machines are designed to cut through hard materials like stone, concrete, and even metals with unparalleled precision. This article explores the features, applications, and benefits of mini diamond wire saws, highlighting why they are increasingly favored by craftsmen and industrial operators alike.

Mini Diamond Wire Saw Technology

The heart of any mini diamond wire saw lies in its technology. These saws utilize a thin, flexible wire embedded with diamond particles that rotate at high speeds to cut through materials. The diamond particles act as the cutting edge, allowing the saw to slice through tough surfaces with minimal effort. This design not only enhances the saw’s cutting capability but also extends its lifespan compared to traditional blade-based systems.

Applications of Mini Diamond Wire Saws

From construction sites to workshops, mini diamond wire saws find diverse applications due to their versatility and portability. They are particularly useful in areas where space is limited or where precision is paramount. For instance, in architectural restoration projects, these saws can make intricate cuts without damaging surrounding structures. Similarly, in the fabrication industry, mini diamond wire saws enable clean, precise cuts on metal sheets and pipes, ensuring a high-quality finish.

Benefits of Using Mini Diamond Wire Saws

One of the primary advantages of using mini diamond wire saws is their ability to maintain consistent performance across different materials. Whether cutting granite, marble, or reinforced concrete, these saws deliver smooth, accurate cuts every time. Additionally, their compact size makes them easy to maneuver in tight spaces, enhancing operational flexibility. This combination of precision and mobility has made mini diamond wire saws a go-to tool for professionals requiring high standards of craftsmanship.

How to Choose the Right Mini Diamond Wire Saw

Selecting the right mini diamond wire saw involves considering several factors such as the material being cut, the required depth of cut, and the specific project needs. For example, if you frequently work with very hard materials, opting for a saw with a higher concentration of diamonds in its wire will ensure durability and efficiency. It’s also important to consider the power source—battery-powered models offer more portability, while those connected to mains electricity might be better suited for continuous use in stationary settings.

Maintenance and Care of Mini Diamond Wire Saws

Proper maintenance is crucial for keeping your mini diamond wire saw in optimal condition. Regular cleaning of the wire and machine components helps prevent wear and tear. Lubricating moving parts ensures smooth operation and extends the life of the equipment. Following manufacturer guidelines for storage and handling can further enhance the longevity of your mini diamond wire saw, ensuring it remains a reliable tool for years to come.

Future Innovations in Mini Diamond Wire Saw Technology

As technology advances, so too does the potential of mini diamond wire saws. Innovations such as improved diamond formulations and more efficient motors promise to further enhance the performance and capabilities of these saws. Additionally, advancements in automation and digital control systems could lead to even more precise cutting operations, opening up new possibilities for industries that rely heavily on precision cutting techniques.

By understanding the technology behind mini diamond wire saws and how they can be effectively utilized, professionals can harness their full potential to achieve superior results in their projects. Whether for detailed craftsmanship or large-scale industrial applications, these powerful yet compact tools continue to redefine what is possible in material cutting.

Request for Quotation

报错: 未找到这个表单