The Releated Products of Mobile Granite Cutting

Mobile Granite Cutting

Table of Contents

Revolutionizing Stone Work: The Advantages of Mobile Granite Cutting

Mobile granite cutting has become an indispensable tool for professionals in the stone industry, offering unparalleled convenience and precision. Whether you’re working on large-scale construction projects or custom home renovations, having access to mobile cutting solutions can significantly enhance your workflow and final product quality.

Enhanced Flexibility with Mobile Granite Cutting

Enhanced flexibility with mobile granite cutting means that artisans and contractors can bring their tools directly to the job site. This eliminates the need to transport heavy slabs of granite back and forth from a stationary workshop, saving both time and resources. By setting up a temporary workstation on location, workers can ensure that every cut is precise and fits perfectly within the space it’s intended for.

Cost-Efficiency through Mobile Granite Cutting

Cost-efficiency through mobile granite cutting is another compelling reason why more businesses are adopting this technology. Traditional methods often require significant investments in infrastructure and manpower, which can drive up costs. In contrast, mobile units are designed to be compact yet powerful, reducing overhead expenses associated with maintaining a large facility. Additionally, because these machines are highly efficient, they help minimize material waste, further contributing to cost savings over time.

Improved Safety with Mobile Granite Cutting

Improved safety with mobile granite cutting cannot be overstressed. When operations are conducted on-site, there’s less risk involved in transporting unfinished products, which could otherwise pose hazards during handling. Furthermore, modern mobile cutters come equipped with advanced dust collection systems and noise reduction features, creating a healthier work environment for all involved. These safety enhancements not only protect employees but also comply with increasingly stringent occupational health standards.

Environmental Benefits of Mobile Granite Cutting

Environmental benefits of mobile granite cutting are substantial. By reducing the need for long-distance transportation of materials, these solutions contribute to lower carbon footprints compared to traditional practices. Moreover, many contemporary mobile cutters utilize water-jet technology, which uses less energy than conventional diamond blade saws while still achieving clean, accurate cuts. This eco-friendly approach aligns well with growing consumer demand for sustainable building practices.

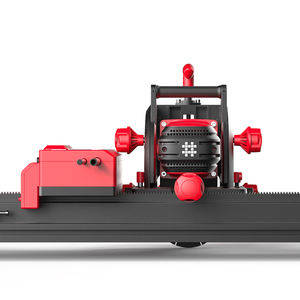

Innovative Design in Mobile Granite Cutting

Innovative design in mobile granite cutting reflects the industry’s commitment to advancing technology for better outcomes. Manufacturers are continuously improving upon existing models by incorporating user feedback and leveraging technological advancements. For instance, some newer units feature intuitive touch-screen controls, automatic calibration functions, and wireless connectivity options that streamline setup and operation processes. Such innovations make these tools even more accessible and user-friendly for professionals at all skill levels.

Future Trends in Mobile Granite Cutting

Future trends in mobile granite cutting suggest that we will see even more sophisticated machines entering the market. As research and development efforts continue, expect to see increased integration of artificial intelligence and robotics in mobile cutting applications. These developments promise to take productivity, accuracy, and customization capabilities to new heights, ensuring that mobile granite cutting remains a vital component of the evolving stone industry landscape.

Request for Quotation

报错: 未找到这个表单