The Releated Products of Onsite Granite Cutting

Onsite Granite Cutting

Table of Contents

The Precision of Onsite Granite Cutting: Enhancing Quality and Efficiency

Onsite granite cutting has revolutionized the way construction and remodeling projects handle natural stone installations. By bringing the workshop to the worksite, this technique ensures a level of precision and efficiency that was previously unattainable. Let’s delve into the benefits, methods, and considerations involved in onsite granite cutting.

Advantages of Onsite Granite Cutting

When it comes to working with granite, every inch matters. Onsite granite cutting offers several advantages over traditional offsite fabrication methods. First, it allows for precise measurements and adjustments that can be made directly on the installation site. This eliminates the need for multiple visits to correct minor discrepancies, saving both time and resources. Additionally, immediate feedback from installers can lead to quicker problem-solving and more accurate final products.

Techniques for Onsite Granite Cutting

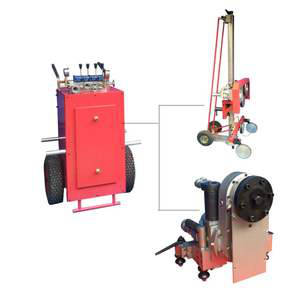

To achieve the best results with onsite granite cutting, specialized tools and techniques are essential. Water jet cutters and diamond blades are commonly used due to their ability to make clean, accurate cuts without damaging the surrounding material. These tools also minimize dust and debris, creating a safer environment for workers and reducing cleanup time post-project. Proper training and safety protocols must always be followed to ensure the highest standards of workmanship and worker protection.

Environmental Impact of Onsite Granite Cutting

One often-overlooked aspect of onsite granite cutting is its environmental impact. Compared to transporting large slabs of granite back and forth between a workshop and job site, performing the cutting on location significantly reduces carbon emissions associated with transportation. Furthermore, water recycling systems can be implemented to reduce water usage during the cutting process, making it a more sustainable option overall.

Cost-Effectiveness of Onsite Granite Cutting

While initial investment in equipment and training may seem high, the long-term cost-effectiveness of onsite granite cutting cannot be overstated. Reduced material waste, fewer trips between sites, and decreased labor hours contribute to substantial savings over time. For businesses looking to streamline operations while maintaining or improving quality standards, adopting this method could represent a significant competitive advantage.

Challenges and Solutions in Onsite Granite Cutting

Despite its many benefits, onsite granite cutting does come with its own set of challenges. Limited space, unpredictable weather conditions, and varying levels of access can all affect the feasibility and efficiency of the process. However, these obstacles can often be overcome through careful planning, use of portable equipment designed for field use, and employing skilled technicians who are adept at working under different circumstances. Effective communication between project managers and field teams is crucial for addressing any issues as they arise.

Future Trends in Onsite Granite Cutting

As technology continues to advance, so too will the capabilities of onsite granite cutting. Innovations in tool design, such as lighter yet stronger materials and more powerful motors, promise to further enhance the precision and speed of the cutting process. Moreover, developments in software solutions for measuring and designing custom pieces may lead to even greater integration between digital planning stages and physical implementation on-site. Staying informed about these trends will help professionals remain at the forefront of the industry.

Request for Quotation

报错: 未找到这个表单