The Releated Products of Plastic Diamond Wire Saw For Marble Profiling

Plastic Diamond Wire Saw For Marble Profiling

Table of Contents

Plastic Diamond Wire Saw for Marble Profiling: Precision, Efficiency, and Durability

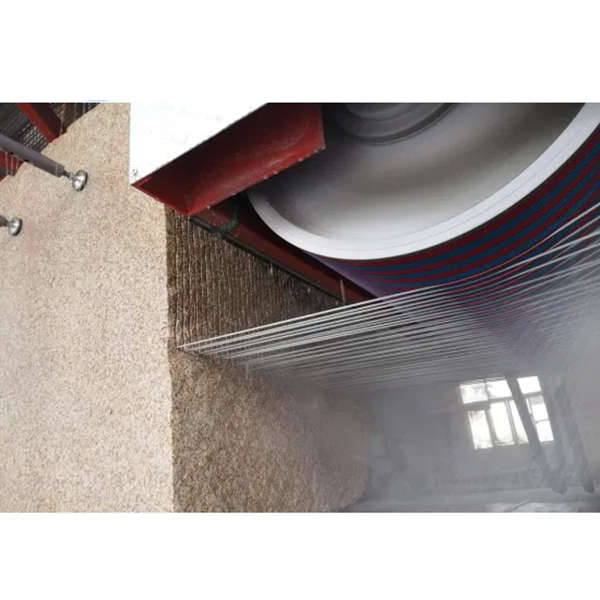

In the world of stone processing, achieving precision while maintaining high productivity is essential. One tool that has revolutionized marble profiling is the plastic diamond wire saw. This innovative technology combines flexibility with cutting-edge design to deliver unparalleled performance. Here’s everything you need to know about how this remarkable equipment enhances the efficiency and quality of marble profiling.

Advantages of Using Plastic Diamond Wire Saws for Marble Profiling

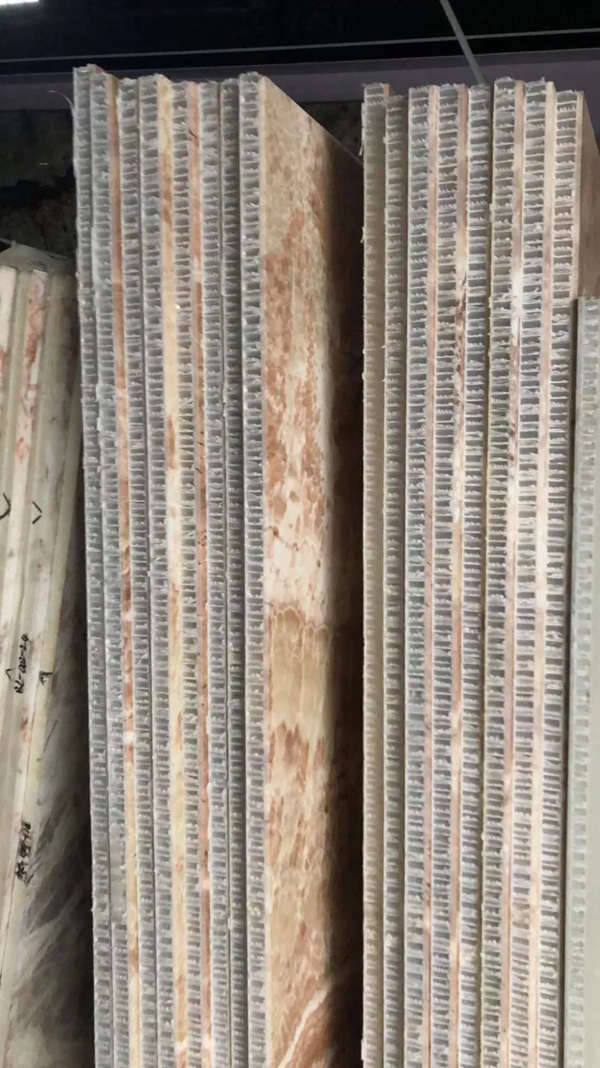

The primary advantage of using a plastic diamond wire saw for marble profiling lies in its ability to cut through the hardest materials with minimal effort. These saws are embedded with synthetic diamonds that can easily slice through marble, providing clean cuts and intricate designs. Moreover, the plastic coating around the wire reduces wear and tear, ensuring a longer lifespan of the tool. As a result, users experience reduced downtime and lower maintenance costs over time.

Innovative Design Enhances Performance in Marble Profiling

The design of plastic diamond wire saws is specifically tailored to meet the demands of marble profiling. Unlike traditional methods, these saws allow for more precise and detailed work, thanks to their thin, flexible wires coated with industrial-grade diamonds. This makes it possible to create complex profiles and shapes in marble slabs without compromising on accuracy or speed. Additionally, the plastic coating helps maintain the integrity of the blade during prolonged use, thus extending its operational life.

Improved Safety Features in Plastic Diamond Wire Saws for Marble Profiling

Safety is always a top priority when operating heavy machinery. Plastic diamond wire saws designed for marble profiling come equipped with advanced safety features that protect operators from potential hazards. These include automatic shut-off mechanisms in case of overheating, ergonomic handles for better grip and control, and robust construction materials that withstand harsh working conditions. Such enhancements not only improve overall safety but also contribute to a more comfortable user experience.

Sustainability and Environmental Impact of Plastic Diamond Wire Saws in Marble Profiling

Considering the growing emphasis on sustainability across industries, it’s crucial to evaluate the environmental impact of tools used in marble profiling. Plastic diamond wire saws have a positive contribution here as well. They produce significantly less waste compared to other cutting methods, primarily because they generate minimal dust and debris during operation. Furthermore, their efficient energy consumption leads to reduced carbon emissions, making them a greener choice for businesses committed to sustainable practices.

Maintenance Requirements for Plastic Diamond Wire Saws Used in Marble Profiling

To ensure optimal performance and longevity of plastic diamond wire saws used in marble profiling, regular maintenance is necessary. This includes cleaning the saw after each use to remove any accumulated residue, inspecting the wire for signs of wear or damage, and lubricating moving parts to prevent corrosion. Following these simple steps can help maintain the saw’s cutting efficiency and prolong its service life, ultimately saving on replacement costs.

Cost-Effectiveness of Adopting Plastic Diamond Wire Saws for Marble Profiling

While the initial investment in plastic diamond wire saws might seem substantial, their long-term benefits far outweigh the cost. Due to their durability and low maintenance requirements, these saws offer excellent value for money. They enable faster project completion times, reduce material wastage, and minimize labor costs associated with manual finishing processes. All these factors contribute to a higher return on investment over time, making plastic diamond wire saws a smart choice for modern marble profiling operations.

By incorporating plastic diamond wire saws into your marble profiling process, you’re not just investing in state-of-the-art technology; you’re also setting yourself up for success in terms of productivity, quality, and sustainability. Whether you’re a seasoned professional or new to the industry, embracing this innovation could mark the beginning of a new era of excellence in your work.

Request for Quotation

报错: 未找到这个表单