The Releated Products of Portable Diamond Wire Saw Machine

Portable Diamond Wire Saw Machine

Table of Contents

Portable Diamond Wire Saw Machine: Precision Cutting on the Go

In the world of construction and demolition, precision and efficiency are paramount. This is where the Portable Diamond Wire Saw Machine shines, offering unparalleled accuracy and flexibility. Whether you’re cutting through reinforced concrete, brick, or stone, this machine provides the power and control needed to tackle even the toughest jobs.

Benefits of Using a Portable Diamond Wire Saw Machine

The Portable Diamond Wire Saw Machine is not just another tool; it’s a game-changer for professionals who require precise, clean cuts. Its portability allows for easy transportation from one site to another, making it ideal for remote locations. Additionally, its compact design doesn’t compromise on performance, ensuring that every cut is as smooth and accurate as possible.

Applications of the Portable Diamond Wire Saw Machine

From bridge repair to architectural restoration projects, the applications of the Portable Diamond Wire Saw Machine are extensive. It excels in scenarios where traditional cutting methods fall short, particularly when dealing with large, irregularly shaped materials. The wire saw can navigate around obstacles, providing a level of versatility unmatched by other cutting tools.

How Does a Portable Diamond Wire Saw Machine Work?

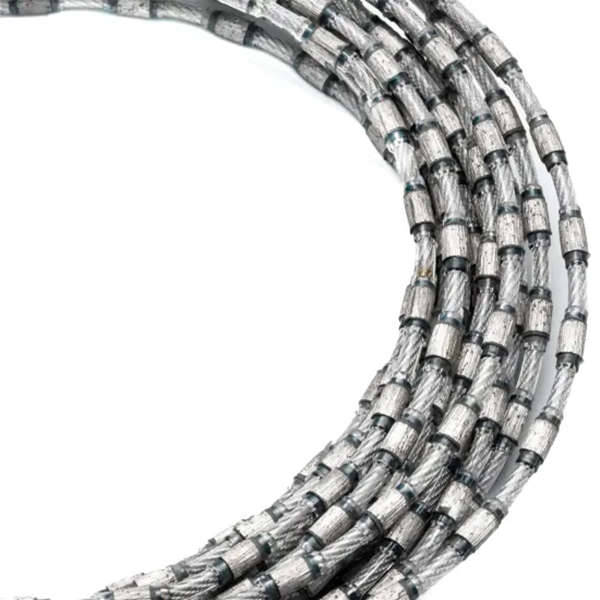

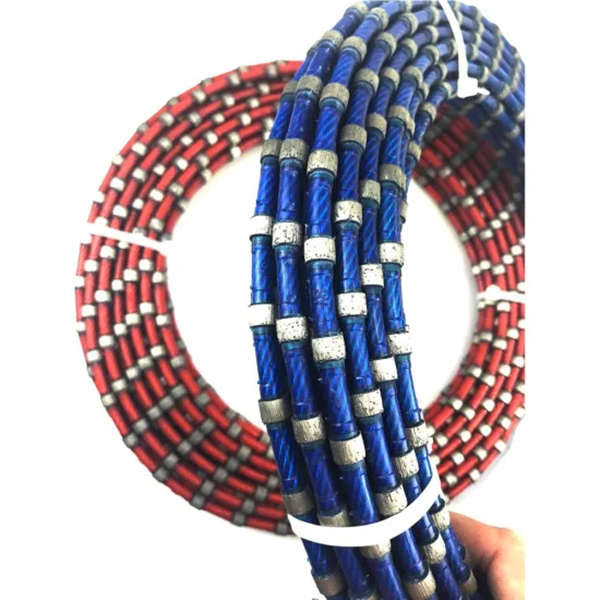

Understanding how the Portable Diamond Wire Saw Machine operates is crucial for maximizing its potential. Essentially, it uses a thin, flexible wire embedded with diamond grains to cut through hard materials. As the wire moves at high speeds, it grinds away at the surface, creating precise cuts. This process is quieter and produces less dust compared to traditional saws, making it suitable for use in noise-sensitive environments.

Choosing the Right Portable Diamond Wire Saw Machine

When selecting a Portable Diamond Wire Saw Machine, several factors come into play. Consider the material you’ll be cutting most often, as well as the depth and thickness required for your cuts. Different machines offer varying wire lengths and tension settings, which affect their overall performance and suitability for specific tasks. Also, look for features like ergonomic handles and adjustable guide wheels that enhance user comfort and control during operation.

Maintenance Tips for Your Portable Diamond Wire Saw Machine

To ensure the longevity and optimal performance of your Portable Diamond Wire Saw Machine, regular maintenance is essential. Keep the machine clean, especially after each use, to prevent debris from damaging internal components. Regularly inspect the wire for wear and tear, replacing it as necessary to maintain cutting efficiency. Lubricating moving parts can also help reduce friction and extend the life of your equipment.

Advancements in Portable Diamond Wire Saw Technology

As technology advances, so do the capabilities of the Portable Diamond Wire Saw Machine. Newer models are incorporating features such as digital controls and improved motor designs that increase cutting speed while reducing energy consumption. These innovations not only make the machines more efficient but also safer and easier to operate, setting new standards in the industry.

By investing in a Portable Diamond Wire Saw Machine, professionals gain access to a versatile tool capable of tackling complex cutting challenges with ease. Whether upgrading existing equipment or entering the market for the first time, understanding these aspects will help ensure you choose the right machine for your needs.

Request for Quotation

报错: 未找到这个表单