The Releated Products of Precision Diamond Wire Saw Machine

Precision Diamond Wire Saw Machine

Precision Diamond Wire Saw Machine: Cutting Through Challenges

Precision diamond wire saw machines have revolutionized the cutting industry, offering unparalleled accuracy and efficiency. Whether it’s slicing through hard materials like concrete or intricate stone work, these machines deliver clean cuts with minimal material loss. This article explores the key features, applications, and benefits of precision diamond wire saw machines, emphasizing their versatility and technological advancements.

Precision Diamond Wire Saw Machine: Unmatched Precision

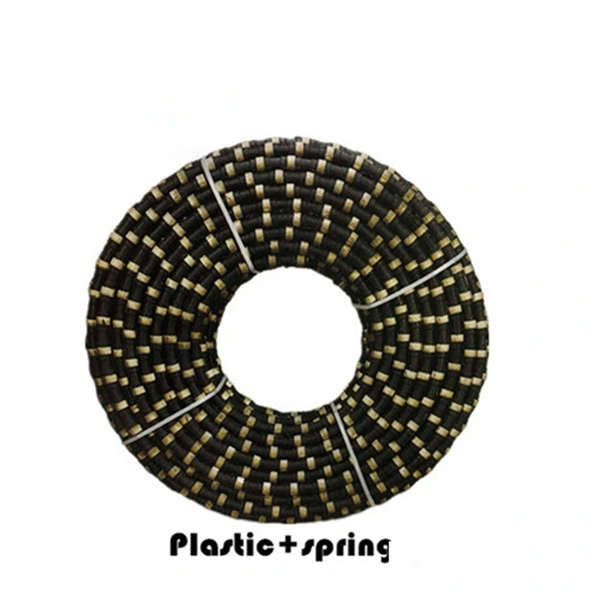

When it comes to precision cutting, few tools can match the capabilities of a precision diamond wire saw machine. These machines use a thin, flexible wire embedded with diamond particles, which rotates at high speeds to cut through various materials. The diamond particles act as cutting edges, providing a smooth and precise cut every time. This technology is particularly useful for applications requiring high levels of accuracy, such as cutting large blocks of granite or marble without damaging the material’s surface.

Applications of Precision Diamond Wire Saw Machine

The applications of precision diamond wire saw machines span across multiple industries, from construction and mining to manufacturing and art. In construction, they are indispensable for cutting reinforced concrete structures with precision, ensuring safety and efficiency during demolition projects. Mining operations benefit from these machines by enabling more accurate extraction of valuable minerals, reducing waste and increasing profitability. Manufacturers appreciate the ability to produce intricate parts with tight tolerances, enhancing product quality and consistency.

Advantages of Using a Precision Diamond Wire Saw Machine

One of the primary advantages of using a precision diamond wire saw machine is its ability to handle complex cuts efficiently. Unlike traditional saws that might struggle with irregular shapes or sizes, diamond wire saws can easily navigate around obstacles, making them ideal for cutting out specific sections from larger pieces of material. Additionally, because the wire does not come into direct contact with the material being cut, there is significantly less heat generated during the process, which helps maintain the integrity of delicate materials.

Maintenance Requirements for Precision Diamond Wire Saw Machine

To ensure optimal performance and longevity, regular maintenance of your precision diamond wire saw machine is essential. This includes inspecting the wire for wear and tear, cleaning debris from moving parts, and lubricating components as needed. Proper storage when not in use also plays a critical role in preserving the machine’s condition. By following manufacturer guidelines for maintenance, operators can minimize downtime and extend the life of their equipment.

Choosing the Right Precision Diamond Wire Saw Machine

Selecting the appropriate precision diamond wire saw machine depends on several factors, including the type of material you will be cutting, the size of the project, and your budget constraints. For instance, if you primarily work with softer stones, a smaller, more portable model may suffice. However, for heavy-duty applications involving harder materials or larger volumes, investing in a robust industrial-grade machine would be more suitable. Consider consulting with industry experts or conducting thorough research to find a machine that best meets your specific needs.

Training and Safety Measures for Precision Diamond Wire Saw Machine

Given the powerful nature of precision diamond wire saw machines, proper training and adherence to safety protocols are paramount. Operators must understand how to correctly set up and operate the machine, as well as recognize potential hazards associated with its use. Safety measures typically include wearing protective gear such as goggles, gloves, and ear protection, keeping bystanders at a safe distance, and ensuring all guards are in place before starting the machine. Regular refresher courses on safety practices can help reinforce good habits among users, contributing to a safer working environment.

Request for Quotation

报错: 未找到这个表单