The Releated Products of Quartzite Blades

Quartzite Blades

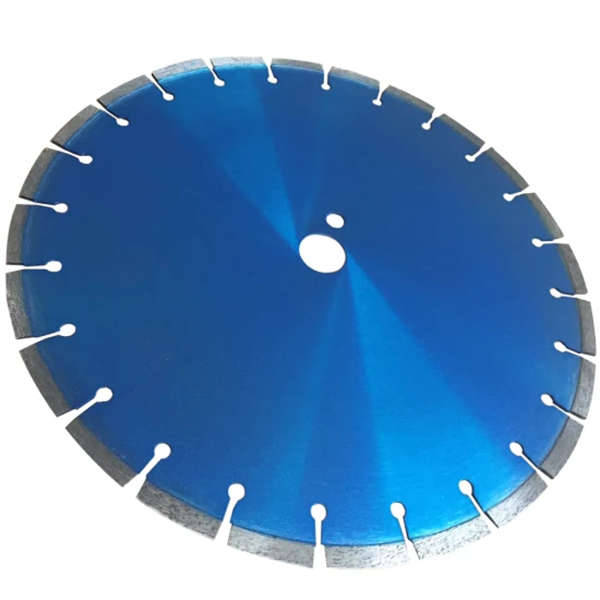

Understanding Quartzite Blades: Durability and Precision

Quartzite blades have become increasingly popular in industrial cutting applications due to their exceptional durability and precision. These blades, often used in the manufacturing and construction sectors, offer unparalleled performance when it comes to cutting through tough materials like stone, concrete, and even certain types of metals. In this article, we delve into the unique properties of quartzite blades and explore how they can revolutionize your operations.

Quartzite Blades: Material Composition

The composition of quartzite blades is crucial to their effectiveness. Made primarily from synthetic or natural quartz, these blades are engineered to withstand high pressures and temperatures, making them ideal for demanding environments. The addition of various binders and reinforcing agents further enhances their strength and resistance to wear. When selecting quartzite blades for your projects, understanding their material composition is key to ensuring optimal performance and longevity.

Benefits of Quartzite Blades in Industrial Applications

Incorporating quartzite blades into industrial processes can yield significant benefits. Their hardness and sharpness allow for precise cuts with minimal effort, reducing the risk of material waste and increasing production efficiency. Additionally, the low maintenance requirements of quartzite blades contribute to cost savings over time. Industries ranging from stonemasonry to automotive manufacturing have witnessed improved quality and productivity thanks to the adoption of these advanced cutting tools.

Maintenance Tips for Quartzite Blades

Proper care and maintenance are essential to extend the life of quartzite blades. Regular cleaning using mild detergents and water helps prevent the accumulation of debris that could dull the blade’s edge. It’s also important to store these blades in a dry environment away from corrosive substances. Periodic inspections for signs of wear or damage ensure that any issues are addressed promptly, preventing potential accidents during operation.

Choosing the Right Quartzite Blades for Your Needs

Selecting the appropriate type of quartzite blade depends on several factors including the material being cut, the thickness of the workpiece, and the specific requirements of your project. For instance, blades designed for cutting softer stones will differ from those intended for harder materials such as granite or marble. Consulting with a knowledgeable supplier can help you choose the best option tailored to your application, ensuring both safety and efficiency in your workflow.

Quartzite Blades vs Traditional Cutting Tools

When compared to traditional cutting tools made from materials like steel or tungsten carbide, quartzite blades stand out due to their superior cutting capabilities and longer lifespan. While initial costs might be higher, the reduced need for frequent replacements and the enhanced precision provided by quartzite blades often result in better value over time. This makes them particularly attractive for businesses looking to upgrade their cutting technology without compromising on quality or operational costs.

Future Innovations in Quartzite Blade Technology

As research and development continue within the industry, we can expect to see advancements in quartzite blade technology. Innovations may include improvements in blade design for even more efficient cutting, as well as the integration of smart technologies that monitor blade condition and performance in real-time. These developments promise not only to enhance current applications but also to open up new possibilities for industries seeking cutting-edge solutions.

By embracing the power of quartzite blades, manufacturers and construction firms alike can achieve greater precision, durability, and efficiency in their operations. Whether you’re just starting to explore the benefits of these advanced tools or looking to optimize your existing setup, investing in high-quality quartzite blades is a step towards achieving excellence in your field.

Request for Quotation

报错: 未找到这个表单