The Releated Products of Rigid Ceramic Tile Saw

Rigid Ceramic Tile Saw

Rigid Ceramic Tile Saw: Precision Cutting for Professional Results

When it comes to cutting ceramic tiles, precision and durability are paramount. A rigid ceramic tile saw stands out as a powerful tool designed specifically for this purpose. Whether you’re a professional contractor or a DIY enthusiast tackling a home renovation project, investing in a high-quality rigid ceramic tile saw can make all the difference. Let’s delve into why these tools are essential and explore their key features.

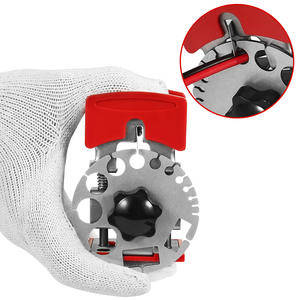

Rigid Ceramic Tile Saw Blades: The Heart of the Tool

The blade is arguably the most critical component of any tile saw, and a rigid ceramic tile saw is no exception. These saws typically use diamond blades, which are known for their ability to cut through hard materials like ceramic and porcelain tiles with ease. Diamond blades come in wet and dry varieties; wet blades require a constant stream of water to prevent overheating and prolong blade life, while dry blades can operate without water but may not last as long. For the best results and longest lifespan, a wet blade is generally recommended for a rigid ceramic tile saw.

Benefits of Using a Rigid Ceramic Tile Saw

Using a rigid ceramic tile saw offers several advantages over other types of tile cutting tools. Firstly, these saws provide unmatched accuracy and clean cuts, crucial for achieving a professional look in your tiling projects. Additionally, they are built to handle large volumes of work, making them ideal for commercial applications or extensive home renovations. Another significant benefit is the reduction in dust and debris during operation, thanks to the water cooling system found in many models. This feature not only keeps the workspace cleaner but also reduces health risks associated with airborne particles.

How to Choose the Right Rigid Ceramic Tile Saw

Selecting the right rigid ceramic tile saw depends on various factors including the size of your project, budget, and specific requirements. For instance, if you’re working on small-scale projects, a compact model with basic features might suffice. However, for larger jobs or frequent use, consider investing in a more robust, heavy-duty option that can handle continuous operation. Features such as blade size, water pump capacity, and adjustability of the cutting guide are important considerations when choosing a rigid ceramic tile saw.

Maintenance Tips for Your Rigid Ceramic Tile Saw

Proper maintenance is essential to ensure your rigid ceramic tile saw performs optimally and lasts longer. Regular cleaning of the machine, especially the blade and water pump, helps prevent clogging and ensures smooth operation. It’s also important to inspect the blade periodically for wear and tear, replacing it when necessary to maintain cutting efficiency. Keeping the saw lubricated and storing it properly when not in use will further extend its lifespan.

Common Issues with Rigid Ceramic Tile Saws and How to Troubleshoot Them

Like any piece of machinery, rigid ceramic tile saws can encounter issues from time to time. One common problem is chipping around the edges of cut tiles, which can often be resolved by adjusting the speed or pressure applied during cutting. If the blade becomes dull prematurely, check the water flow to ensure it’s adequate for cooling. In some cases, using the wrong type of blade for the material being cut can lead to poor performance; always verify that you’re using the correct blade for your specific needs.

By understanding the features, benefits, and proper care of a rigid ceramic tile saw, you’ll be well-equipped to select and maintain this invaluable tool. Whether you’re a seasoned professional or new to the world of tiling, investing in a quality rigid ceramic tile saw will undoubtedly enhance your capabilities and results.

Request for Quotation

报错: 未找到这个表单