The Releated Products of Speed Tile Cutter

Speed Tile Cutter

Table of Contents

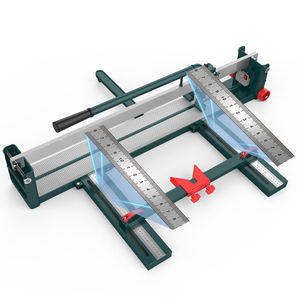

Speed Tile Cutter: Precision, Power, and Performance

In the world of construction and home renovation, the efficiency and accuracy of tools can make or break a project. One such indispensable tool is the speed tile cutter, designed to meet the demands of professionals and DIY enthusiasts alike. This article delves into the features, benefits, and considerations when choosing a speed tile cutter, ensuring your next tiling project goes smoothly.

Understanding the Basics of Speed Tile Cutters

Before diving into specifics, it’s essential to understand what a speed tile cutter is and how it works. Essentially, these machines use a diamond blade to score tiles, making precise cuts for a clean break. They come in various sizes and configurations, from compact handheld models to larger, more powerful stationary units. The key advantage of using a speed tile cutter over traditional methods is its ability to achieve straight, accurate cuts quickly—hence the term “speed.”

Selecting the Right Speed Tile Cutter

When shopping for a speed tile cutter, several factors come into play. Consider the size of the tiles you’ll be working with, as well as the volume of work. For small-scale projects or occasional use, a portable model might suffice. However, if you’re tackling large areas or have frequent need, investing in a heavy-duty, stationary speed tile cutter could save time and effort in the long run. Additionally, look for features like water cooling systems to reduce dust and prolong blade life, ergonomic handles for comfort during extended use, and adjustable guides for enhanced accuracy.

Maintenance and Care of Your Speed Tile Cutter

Like any piece of machinery, regular maintenance is crucial for keeping your speed tile cutter in top condition. Start by cleaning the machine after each use to prevent debris buildup. Pay special attention to the cutting wheel, ensuring it remains free of clogs and damage. Lubricate moving parts as recommended by the manufacturer to ensure smooth operation. Lastly, store your speed tile cutter in a dry place away from extreme temperatures to protect its components and extend its lifespan.

Tips for Using a Speed Tile Cutter Efficiently

To get the most out of your speed tile cutter, follow these tips:

– Always wear appropriate safety gear, including goggles and gloves.

– Measure twice, cut once. Use a square or laser level to mark your tiles accurately before cutting.

– Gradually apply pressure when cutting to avoid chipping or breaking tiles.

– Experiment with different speeds and blade types to find what works best for your specific materials and tasks.

Advantages of Using a Speed Tile Cutter Over Other Methods

Compared to manual scoring tools or angle grinders, speed tile cutters offer several advantages. They provide unparalleled precision, making them ideal for intricate designs and tight spaces. The speed at which they operate also boosts productivity, allowing professionals to complete jobs faster. Moreover, many modern models are designed with user safety in mind, incorporating features like automatic shut-offs and protective guards.

Frequently Asked Questions About Speed Tile Cutters

Q: Can I use my speed tile cutter on different types of materials?

A: Yes, most models can handle various materials, including ceramic, porcelain, stone, and glass. However, you may need to switch out blades depending on the hardness of the material being cut.

Q: How often should I replace the cutting blade?

A: Blade lifespan varies based on usage frequency and the type of material being cut. Generally, inspect your blade regularly for signs of wear and replace it when it begins to dull or chip.

By choosing the right speed tile cutter and maintaining it properly, you can ensure that every tiling project—from bathroom renovations to kitchen backsplashes—is completed with precision and professionalism. Whether you’re a seasoned contractor or a weekend warrior, investing in quality tools like a speed tile cutter will pay dividends in terms of both time saved and satisfaction with the final result.

Request for Quotation

报错: 未找到这个表单