The Releated Products of Trac Star Granite Saw

Trac Star Granite Saw

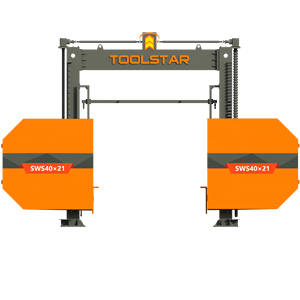

Trac Star Granite Saw: Precision Cutting for Professional Applications

In the world of construction and stonework, precision and efficiency are paramount. The Trac Star Granite Saw has emerged as a game-changer, offering unparalleled accuracy and speed. Whether you’re a seasoned professional or just starting out in the industry, understanding the features and benefits of this machine can significantly enhance your work. This article delves into the details of the Trac Star Granite Saw, exploring its capabilities, applications, and what sets it apart from other cutting solutions.

Trac Star Granite Saw: Robust Design and Durability

The Trac Star Granite Saw boasts a robust design engineered to withstand the rigors of daily use. Constructed with high-quality materials, this saw ensures durability and longevity, making it a reliable choice for demanding projects. Its sturdy frame and powerful motor are built to last, providing consistent performance even under heavy loads. This makes the Trac Star Granite Saw ideal for both commercial and industrial applications where reliability is key.

Enhancing Efficiency with the Trac Star Granite Saw

One of the standout features of the Trac Star Granite Saw is its ability to enhance efficiency on the job site. Equipped with advanced cutting technology, this saw allows for quick and precise cuts through granite and other hard materials. The saw’s design includes features such as automatic water cooling systems and adjustable cutting depths, which contribute to smoother operations and reduced downtime. By improving workflow, the Trac Star Granite Saw helps contractors meet tight deadlines without compromising on quality.

Trac Star Granite Saw: Versatility in Cutting Applications

The versatility of the Trac Star Granite Saw extends its utility across various cutting applications. Whether you need to cut straight lines or intricate designs, this machine delivers exceptional results every time. It is particularly well-suited for cutting granite countertops, paving stones, and monuments. With its interchangeable blades, the Trac Star Granite Saw can also tackle softer materials like marble, adding to its adaptability in different projects.

Advantages of Using the Trac Star Granite Saw

Using the Trac Star Granite Saw comes with numerous advantages that benefit both the user and the end product. Firstly, its ergonomic design reduces operator fatigue, allowing for longer working hours. Secondly, the saw’s dust collection system minimizes mess and creates a cleaner working environment. Lastly, the precision offered by the Trac Star Granite Saw ensures that each cut meets the highest standards of quality, enhancing the overall value of any project.

Maintenance and Care for Your Trac Star Granite Saw

To ensure optimal performance and longevity, proper maintenance of your Trac Star Granite Saw is essential. Regular cleaning, lubrication of moving parts, and checking for wear are crucial steps in maintaining the saw’s efficiency. Additionally, using manufacturer-recommended replacement parts and following the service schedule outlined in the owner’s manual will help keep your machine running smoothly.

Investing in the Future with the Trac Star Granite Saw

Investing in a Trac Star Granite Saw represents more than just acquiring a tool; it’s investing in the future of your business. This saw not only increases productivity and profitability but also opens up new possibilities for taking on more complex and diverse projects. As demand for high-quality stone cutting continues to grow, having the right equipment can give you a competitive edge in the market.

By choosing the Trac Star Granite Saw, professionals gain access to a powerful, versatile, and efficient tool designed to meet the challenges of modern stonework. Its combination of robust design, enhanced efficiency, and wide-ranging applications makes it a valuable asset for any serious contractor or artisan looking to elevate their craft.

Request for Quotation

报错: 未找到这个表单