The Releated Products of Vertical Diamond Wire Saw

Vertical Diamond Wire Saw

Understanding the Vertical Diamond Wire Saw: A Precision Tool for Modern Cutting Needs

In the realm of industrial cutting, precision and efficiency are paramount. One tool that has revolutionized the way we approach complex cutting tasks is the vertical diamond wire saw. This advanced machinery offers unparalleled accuracy and versatility, making it indispensable across various industries. From construction to mining, understanding how these saws operate can unlock new possibilities for your projects.

Vertical Diamond Wire Saw: An Overview

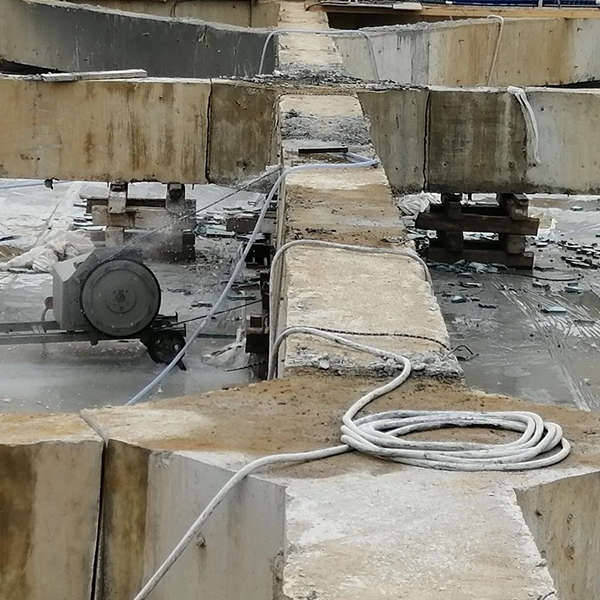

A vertical diamond wire saw consists of a thin, flexible wire embedded with diamond particles. These particles serve as the cutting edge, allowing the saw to slice through materials like stone, concrete, and metal with remarkable ease. The wire is continuously fed between two pulleys, one of which is driven by a motor. This continuous motion ensures a smooth, controlled cut every time.

Key Components of a Vertical Diamond Wire Saw

To appreciate the full capabilities of a vertical diamond wire saw, it’s essential to examine its key components. The diamond-impregnated wire is the heart of the system, responsible for all cutting activities. Pulleys guide the wire, maintaining tension and ensuring proper alignment during operation. Motors provide the power needed to drive the pulleys, while control systems allow operators to adjust speed and direction precisely.

Applications of the Vertical Diamond Wire Saw

The versatility of vertical diamond wire saws makes them suitable for a wide range of applications. In construction, they are used for demolition and renovation projects where precise cuts are required. For example, cutting large blocks of granite or marble for architectural use. In the mining industry, these saws help extract valuable minerals from quarries efficiently without damaging the surrounding rock formations.

Advantages of Using a Vertical Diamond Wire Saw

When compared to traditional cutting methods, using a vertical diamond wire saw presents several advantages. Firstly, it produces minimal noise and vibration, reducing workplace disruption. Secondly, the water-cooled cutting process minimizes dust generation, creating a safer environment for workers. Lastly, the ability to make clean, straight cuts in any direction increases productivity and reduces material waste.

Maintenance and Safety Considerations for Vertical Diamond Wire Saws

Like any piece of heavy machinery, regular maintenance is crucial for prolonging the lifespan of a vertical diamond wire saw. This includes inspecting the wire for wear and tear, lubricating moving parts, and cleaning debris from the machine after each use. Safety should also be a top priority; operators must wear appropriate protective gear and follow established guidelines to prevent accidents.

Future Innovations in Vertical Diamond Wire Saw Technology

As technology continues to evolve, so too does the design of vertical diamond wire saws. Innovations such as smart sensors and automated controls are being integrated into newer models, enhancing their performance and ease of use. Research into more durable diamond compounds promises to further improve cutting efficiency and reduce operational costs.

By embracing the power of vertical diamond wire saws, businesses can achieve greater precision, speed, and cost-effectiveness in their operations. Whether you’re tackling a challenging construction project or need to extract resources from hard-to-reach locations, this cutting-edge tool stands ready to meet your needs.

Request for Quotation

报错: 未找到这个表单